Jun

Vision, Robotics & Motion 2024 in 70 seconds

Vision, Robotics & Motion is the trade fair in the Benelux in the field of automating production processes. This year we were again present at this...

Stöber Antriebstechnik GmbH & Co KG established in 1934 and with headquarters in Pforzheim. Recent decades Stober specializes in the development and manufacture of precision gears, servo drives and controllers. Stober is an important partner and supplier of ATB Automation since 1954. ATB Automation is a certified TOP dealer and responsible for the customers in the Benelux.

Stöber Antriebstechnik is a family business founded in 1934. From te beginning large and familiar with manually adjustable speed drives and grown to a specialist in the field of high-precision and dynamic servo systems.

At the moment, the strategic direction is determined by the third generation Andreas Thiel (left) and Patrick Stöber (right). Since 2023, they have handed over day-to-day management to Managing Director Rainer Wegener (middle), who has been with Stöber Antriebstechnik since 2001.

The Stober systems and components are used worldwide.

In these countries Stober established with a service and sales office:

- Germany - United Kingdom - France - Italy - Austria - Switzerland - Turkey

- United States

- China - Taiwan - Japan

Additionally Stober is represented in many industrial countries by dealerships with sales and service facilities such as ATB Automation in the Benelux.

Manufacturing and assembly facilities are available in:

- Germany (Pforzheim)

- United States (Maysville - KY)

Quality from home" is the motto of Stöber.

The park machines includes renowned brands such as Gleason, Gildemeister, Reishauer and Studer.

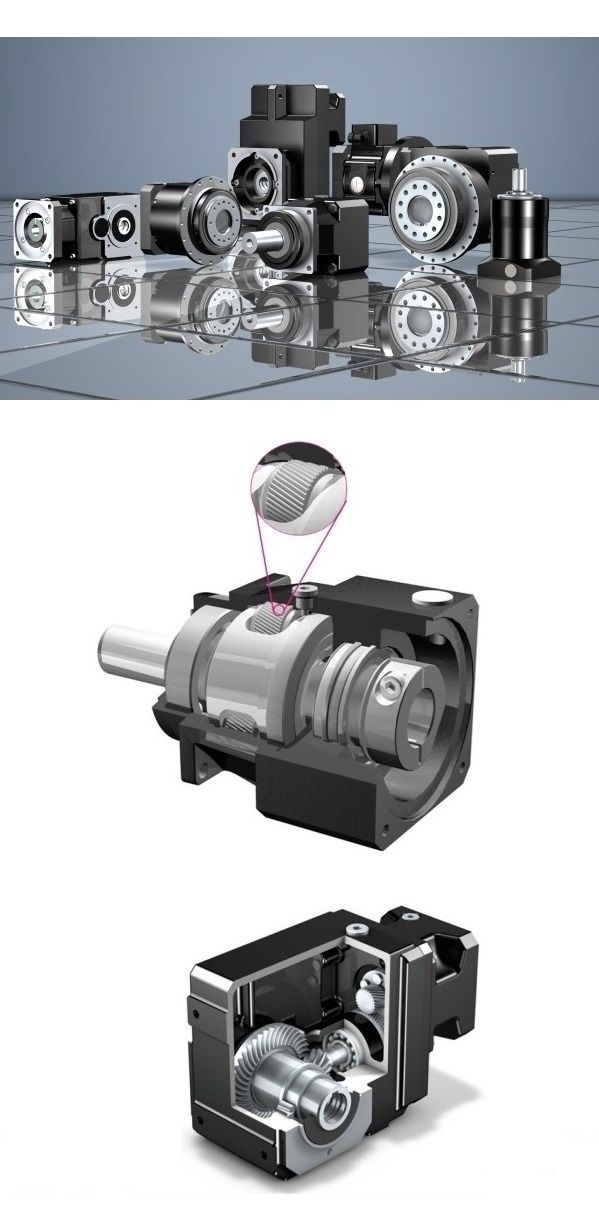

The housings of the gearboxes are machined from a single piece with a minimum number of fixtures. This results in the most accurate alignment and a maximum torsional stiffness.

All gear teeth such as the right-angle bevel gears, pinions, planet and sun gears, as well as the internal toothing in the housing of the planetary gears, have an helical toothing.

The teeth of precision planetary gearboxes have an extra honing operation. Honing is a chipping precision machining by grinding of the teeth in the axial direction.

This production results in gearboxes suitable for precise and dynamic servo applications:

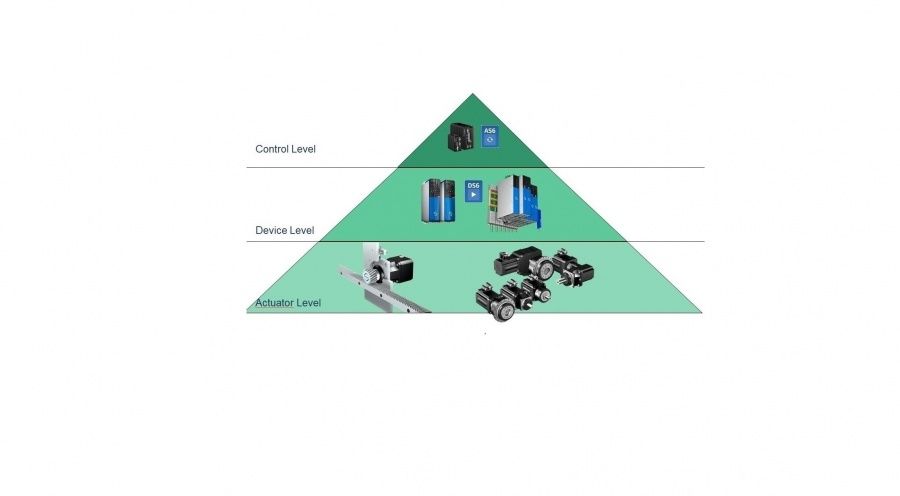

Actuator Level: Base is the wide range of precision gearboxes with servo motors and / or racks. For each application a constructive good solution.

Device Level: Stober controllers with positioning functionality equipped with EtherCAT or Profinet.

Control Level: Stober control system with control based motion control via EtherCAT.

At each level the components can be combined with another brand of servo motors, drives or operating system.

Easy mounting servomotors

Planetary gearboxes

Bevel gearboxes

In addition to planetary gears with angular stages there are precise angle helical bevelgearboxes and helical worm gearboxes available. These gears gives an engineer many cost-effective solutions with the design and construction.

Synchronous servomotors with permanent magnets. Optimal design, like the stator with orthocyclic coil.

Available with single or multi-turn EnDat 2.2 or Hyperface encoders with electronic nameplate for the Stober inverters.

With optional encoders, adjustment and connectors for third-party drives, among others, Siemens, Bosch Rexroth, SEW, B & R and Beckhoff.

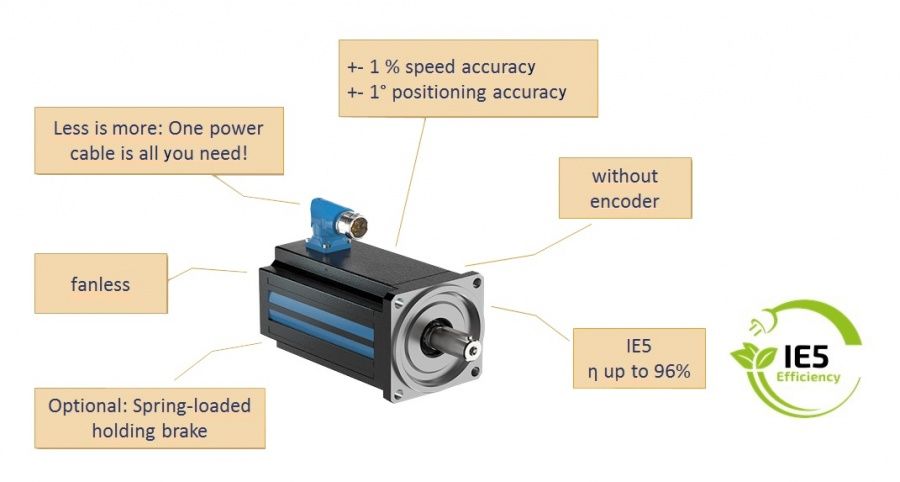

Is an asynchronous motor too big and not efficient enough for you? Or are you looking for an inexpensive and rugged alternative to the synchronous servo motor? Based on the "bridge the gap" principle, STOBER has brought a new motor class to market.

The consistently encoderless Lean motors are strong and rugged like asynchronous drives and precise and compact like synchronous servo motors. For example, the motors can be used for automation tasks in harsh production environments.

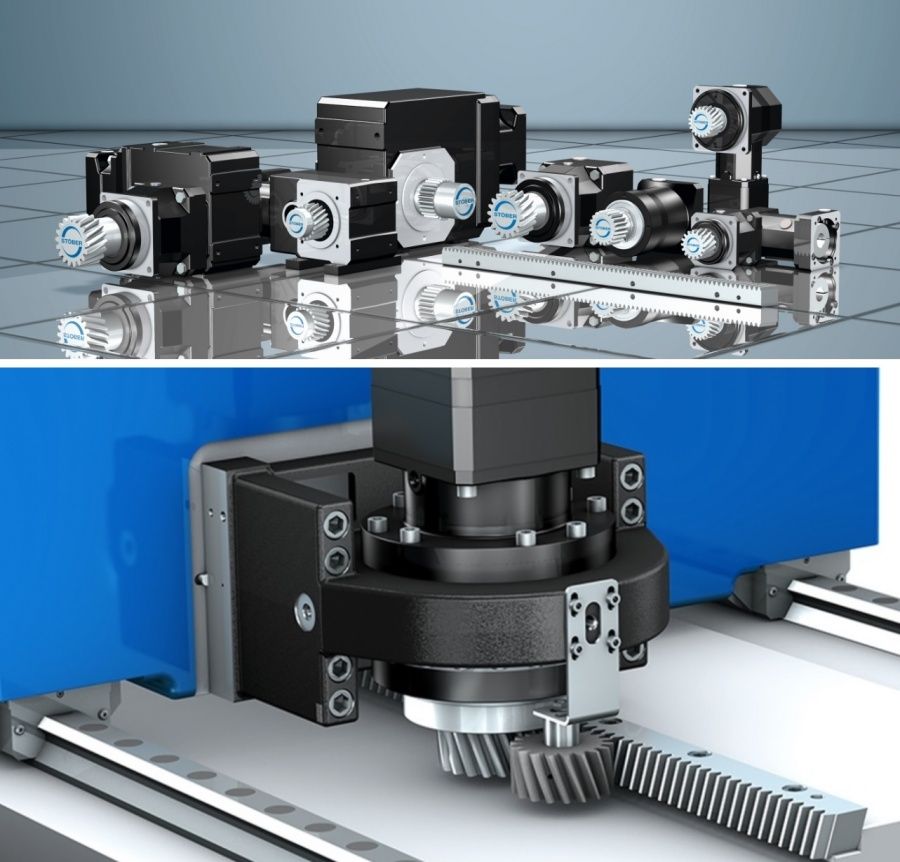

The Stober geared servo motors are built from the broad range of planetary gear and helical-bevel gear units combined with the compact servo motors.

The servo motor is assembled directly without adapter and coupling.

This construction without adapter and coupling has many advantages:

The Stober servo drives from the 6th generation with a servo cycle time of 62.5 ns and 25-bit encoder resolution are ideal for highly dynamic and accurate applications.

Control by the CiA402 (Can in Automation) protocol:

In addition, the SD6 drive controller is also suitable for positioning control with a Stober protocol via EtherCAT, Profinet or analog / digital inputs and outputs.

Because of the precise and dynamic servo systems Stober is a major global supplier for specific markets, such as:

Especially for these focus markets some specific products are developped.

High performance servo gear unit with support bearing:

The ATB Automation team has a strong bond and short lines with specialists from Stöber Antriebstechnik.

With the proper training and many years of experience ATB Automation is the right partner for engineers and machine builders in the Benelux:

Compact motors with high efficiency (IE5). The solution between asynchronous motors and synchronous servomotors. It is possible to position without an encoder.

Compact motorgears with high efficiency (IE5). The solution between asynchronous motors and synchronous servomotors. It is possible to position without an encoder.

Vision, Robotics & Motion is the trade fair in the Benelux in the field of automating production processes. This year we were again present at this...

The EtherCAT Technology Group keeps EtherCAT technology open to all potential users. It brings together manufacturers of EtherCAT equipment,...

STOBER has enhanced its SC6 and SI6 series drive controllers with additional PROFINET functions and having redeveloped SU6 module, the controllers...

With the innovative system concept for rack and pinion drives, STOBER has developed a compact, easy-to-use system with process reliability that is...

STÖBER Antriebstechnik has further advanced its One Cable Solution (OCS) in collaboration with encoder manufacturer HEIDENHAIN, bringing the...

The company Wadcon Automation, located in Groningen, specializes in the construction of special machines for the automation industry. From one of her...

The new generation of servo planetary gear units from STÖBER Antriebstechnik offers drives that are the most compact on the market in their power...

The Stöber lean motor is a revolutionary development and may also be the ideal solution for drive issues for your developments. The lean motor is a...

Stöber recently launched a revolutionary engine: the so-called lean motor. Is an asynchronous motor too big and not efficient enough for you? Or are...

Precision racks with twice the bores! Did you know that gear racks were originally used to place objects at different heights? For example, they...

A safe machine with minimal downtime, without compromises on performance because safety techniques throw a spanner in the works. “That sounds...

The range of manufacturers of servo drives is large... let's say very large. Not surprising given that automation with flexibly adjustable machines...

STOBER has further advanced its One Cable Solution (OCS) in collaboration with encoder manufacturer HEIDENHAIN, bringing the next generation to the...

On Wednesday 7 and Thursday 8 June 2023, we were present at the Vision, Robotics & Motion trade fair in the Brabanthallen in...

The EtherCAT Technology Days took place on 11 and 12 April 2023, right in the technological heart of Twente and Eindhoven. Participants learned all...

Precision in size XL With its fourth generation of PH series servo planetary gear units, STOBER presents precision gear units that are the largest...

It has been a while ago, but on Saturday June 9th once again the annual event “Stöber im Motion” the Mountainbike-event was oraganized by...

Wadcon Speciaalmachinebouw designs and realizes machines which can’t be find in a catalog. We focus on three product groups: assembly machines,...

Location Netherlands

Vermogenweg 109

NL-3641 SR MIJDRECHT

THE NETHERLANDS

Contact information:

Tel +31 297 28 58 21

Location Belgium

P. Basteleusstraat 2 - Unit 11

B-1600 SINT-PIETERS-LEEUW

BELGIUM

Contact information:

Tel. +32 2 588 80 05

Benelux

ATB Automation

Vermogenweg 109

NL-3641 SR MIJDRECHT

NETHERLANDS

Benelux

VAT NL 003226591B01

Chamber of Commerce 30100549

IBAN NL93 HAND 0784 5271 80

BIC HANDNL2A

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.