2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

With the new design of the ServoFit® PE planetary gear unit, STÖBER is adding special versions for automation and robotics functions to its servo gear unit range. In line with the reputation of the helical gearing specialist, this new gear units is also equipped with this system.

With its helical gearing, the PE planetary gear unit represents a first in its product and price category. When compared with the spur gear units previously in standard use, it is clear that the helical gearing ensures very low noise levels and high smoothness of operation. Plus there is the high housing stability provided by the ingenious monobloc construction with integral motor adapter for mounting of standard servo motors.

The market launch of the ServoFit® PE planetary gear unit covers sizes PE2 to PE5, all being available in single and two stage versions up to i = 100. The two stage units also feature the monobloc housing.

Two gantry robots for a repacking line with a working range of 2200 x 2030 x 1900 mm in the X-Y-Z plane where crates are stacked. The capacity of the stackers is calculated on crates of 10 kg and 6 cycles/min. There is also a product transfer unit in the repacking line with a working area of 1700 x 600 mm for handling rejected products.

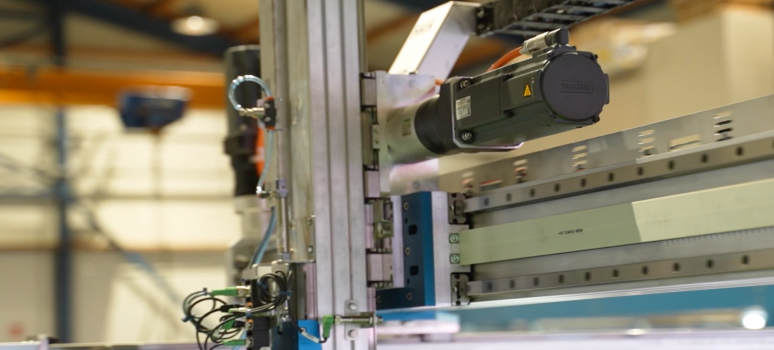

The basis of the systems are the robust HSB portal axles from the Gamma series with double recirculating ball guides and toothed belt transmission. Due to the limited installation height, telescopic axes for the Z-movement have been used here. The linear modules are equipped with our Stöber planetary gearboxes, flexible for mounting any type/brand of servo motor.

Flexible programmable 4-axis palletizer robot. Heart in this application is the Trio Motion Controller where the 4 axis robot with 4 Leadshine servo drives is controlled via a coordinate transformation. The fast EtherCAT connection between the Trio MC4N-ECAT controller and the drives ensures accurate and simple communication. In addition to the Trio Motion Controller, mechanical components are also used, such as a slewing ring bearing for the rotation movement and a rack and pinion for the horizontal movement. Each servo shaft is equipped with a Stöber planetary gearbox or angle worm gearbox.

The Stober ServoFit® gearboxes are available with a flexible system adapter and couplings for many servomotor

Assembly of the servo motor is simple. If desired, this can be carried out at the workshop of ATB Automation.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.