2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

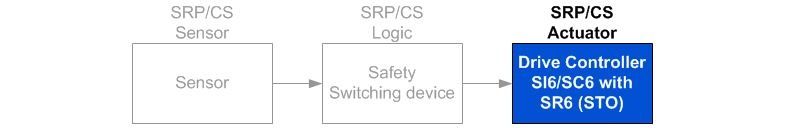

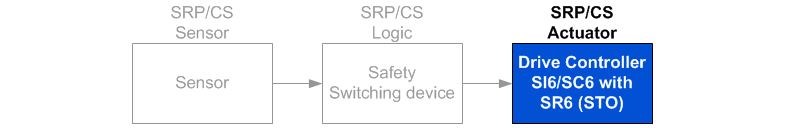

The SR6 safety function is an extension of the SB6, SI6 or SC6 servo drive. With the SR6 option the servo drive can be included as an actuator in the safety circuit (SRP / CS) for the redundant switching off of the torque (Safe Torque Off, STO).

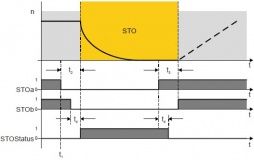

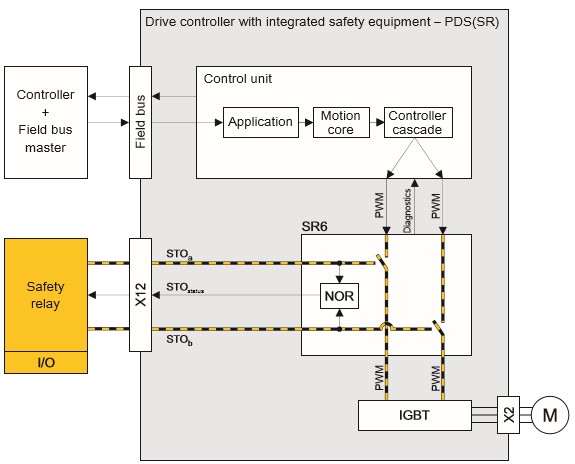

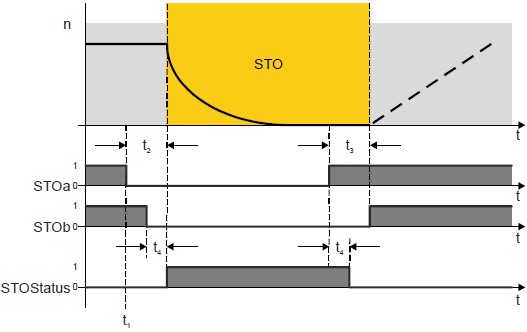

The safety function has a two channel design. Both channels STOa and STOb are independent and must both be connected to 24Vdc in order to enable the motor torque (STO function not active). In this situation, the STO status signal is also not active.

If one of the two (or both) channels STOa or STOb is not connected to 24Vdc, the PWM signal to the power stage of the servo drive is switched off redundantly so that the motor can no longer apply torque. The STO status signal is active in that case.

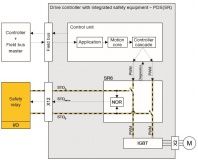

The signal flow of the STO function of the Stöber SI6 / SC6 servo drive with SR6 option is shown in the figure below. The STOa and STOb signals are switched using a safety relay or safety PLC (SRP / CS Logic). In this way a Performance Level PLe (Category 4) can be achieved according to EN ISO 13849-1 or SIL CL3 according to EN 62061 or SIL 3 according to EN 61508.

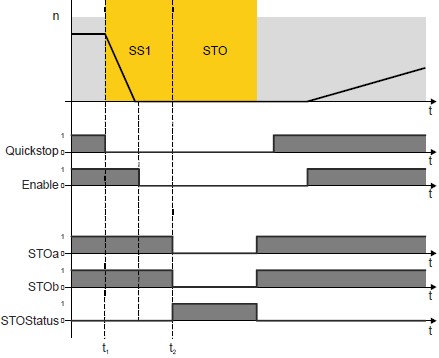

By using a safety relay or safety PLC with switch contacts incuding time delay, Safe Stop 1 function (SS1) on the SR6 option can also be realized according to EN 61800-5-2 and EN 60204-1. In addition to the Enable signal, a Quickstop signal is connected to the servo controller.

The signal flow of the SS1 + STO function of the Stöber SI6 / SC6 servo drive is shown in the diagram below.

The safety relay or safety PLC activates the SS1 safety function at time t1 via the Quickstop signal. After the delay time in the safety relay or safety PLC, the STO signal (a + b) becomes active at time t2. This process corresponds to "time-controlled SS1" definition of EN 61800-5-2.

The safety functions STO and SS1-t concern the complete SI6 or SC6 module and are not axis pecific. On dual axis controllers, both axis are brought into a safe state at the same time. An activated SS1 can not be interrupted.

The software engineers at ATB Automation assist in programming and commissioning via the help desk or on site

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.