2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

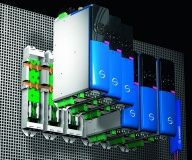

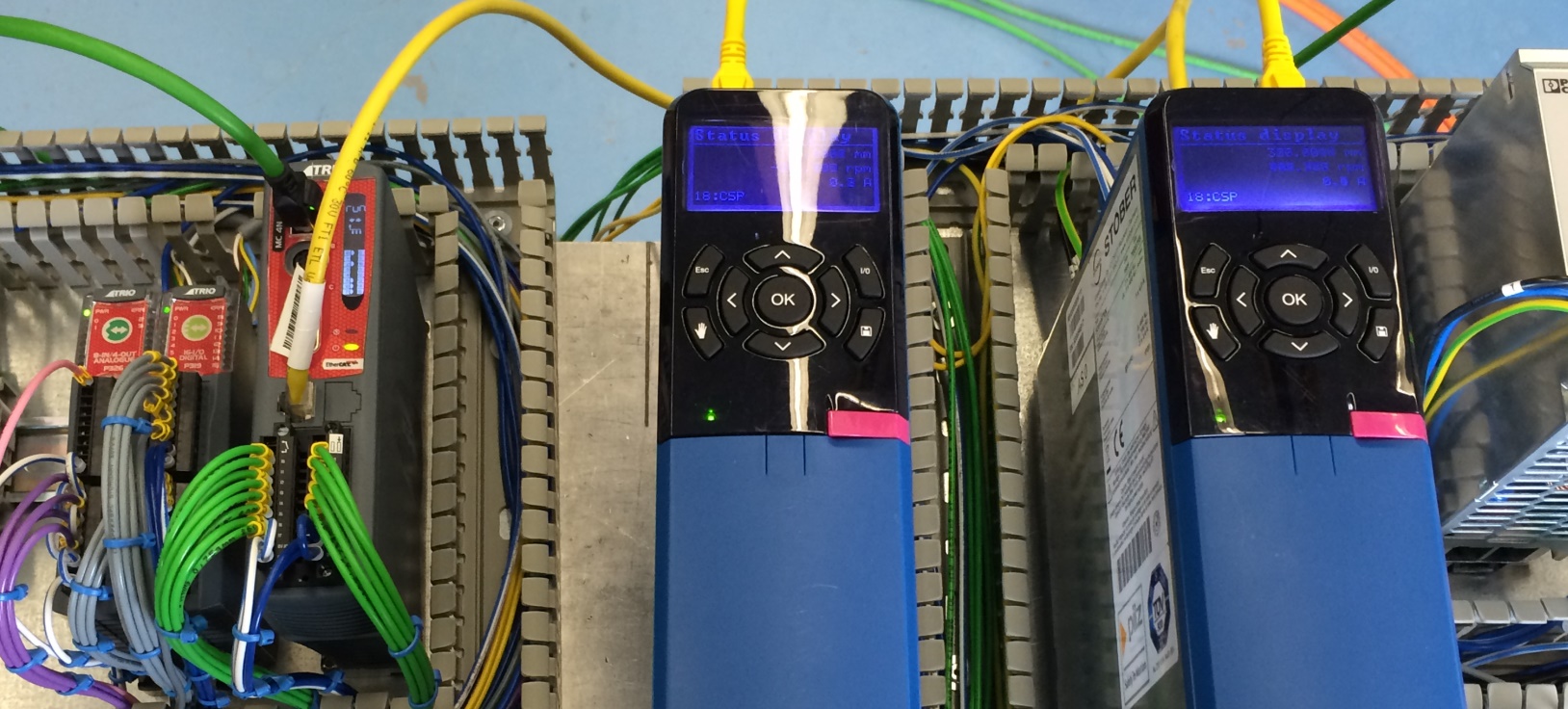

Very fast and precise digital drive control for synchronous servo drives with absolute EnDAT encoder.

For motor power from 0.75 up to 50 kW.

These drive controllers guarantee precision and timing in all circumstances for multiaxis applications with high dynamics.

Position, speed and torque control of the servo axes are calculated at a cycle time of 62.5 μs (16 kHz).

High resolution: for EnDAT2.2 encoder (25 bits per turn).

Suitable for drive based en controller based control (CiA402) via EtherCAT, ProfiNET or CANopen.

Complete motion control solution with Stöber MC6 motion controller, based on CODESYS V3 programming software.

Non-wearing electronic safety function: Safe Torque Off (STO).

Ensures that no torque-generating energy is supplied to the motor and the drive is reliably torquefree. This function forms the basis for many other safety functions.

Nominal currents from 1,5 A to 85 A (peak up to 150A).

Power supply drive controls:

External 24V auxiliary power.

Paramodul (plug-in memory) with integrated micro SD card for storage of all device data.

Fieldbus modules:

Expandable with additional I/O cards for additional analog or digital inputs and outputs.

Integrated control for 24V holding brake (<= 2.5 A).

Integrated filter and fan.

All the SD6 drive controllers sizes can be interconnected via the Quick DC Link, a rear-mounted module offering a secure and efficient bus connenction for a common DC link configuration.

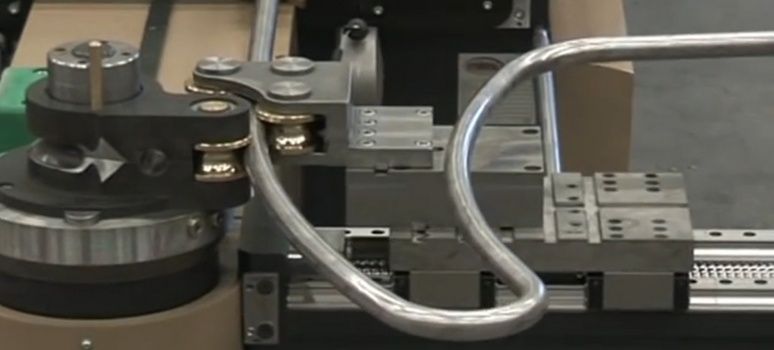

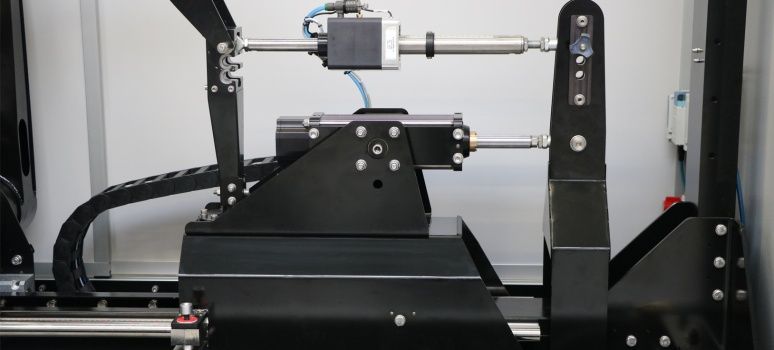

Bending machine for cold forming of tubes and profiles in draw bending operation, driven by Stöber servo drives.

In the production of marshmellows, the product is chopped by means of a knife driven by the Exlar GTX servo actuator. Due to the roller screw transmission, the actuator is suitable for a high duty cycle and a long service life is guaranteed. The actuator is equipped with an encoder suitable for control by the Stöber SD6A servo controllers.

With this GTX80 actuator, forces of up to 2 kN can be achieved in combination with a speed of 1100 mm/s.

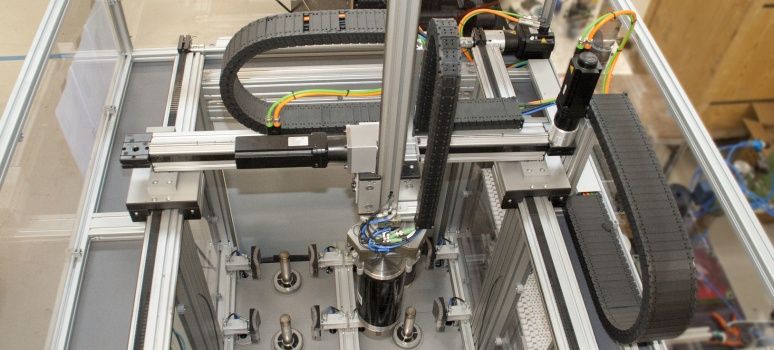

Compact Stöber planetary servo motor gears control an xyz system for handling isolation containers in a test machine. The XYZ system places the isolation container on one of the six test positions. After verification of the measurement system to the XYZ system picks up the container and place it on the rotator. Since the container is reversed by a fourth servo motor Stöber for the correct starting position for the next processing step.

The challenge in this system was the dynamic handling of a product with substantial mass of 25 kg, with speeds up to 2.5 m/s and accelerations of up to 5 m/s2. Using the calculations and the advices of ATB Automation a compact system is the result. The Stöber SD6 servodrives with EtherCAT in combination with Trio MC4N-ECAT motion controllers are easily and quickly connected and installed.

The standard STO safety card (Safe Torque Off) in the Stöber SD6 drives allows the integration of safety into the machine very easy. Safety of the operators is therefore guaranteed at all times.

A multi radius bending machine for products with multiple radii as well with different diameters, time-saving must be achieved by bending in one single cycle. Some examples are tubes for furniture and automotive.

Fully servo driven machine to achieve the highest performance:

- Pipe diameters up to 25 mm with a thickness of 2.5 mm

- Bending moment 1000 Nm

- Clamping force 25 kN

- Bending speed 540 deg / s

- Feed speed of 2100 mm / s

- Rotation speed 720 degrees / s

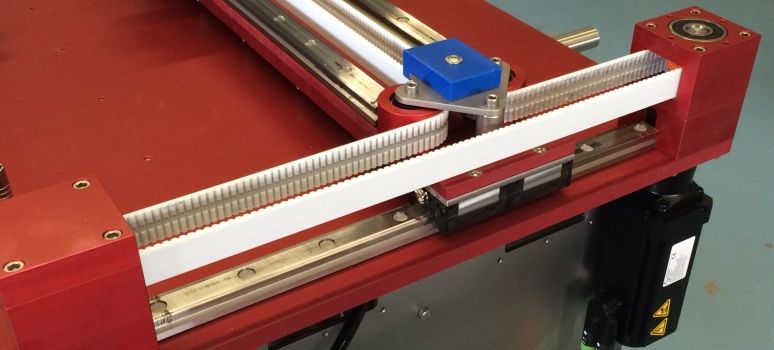

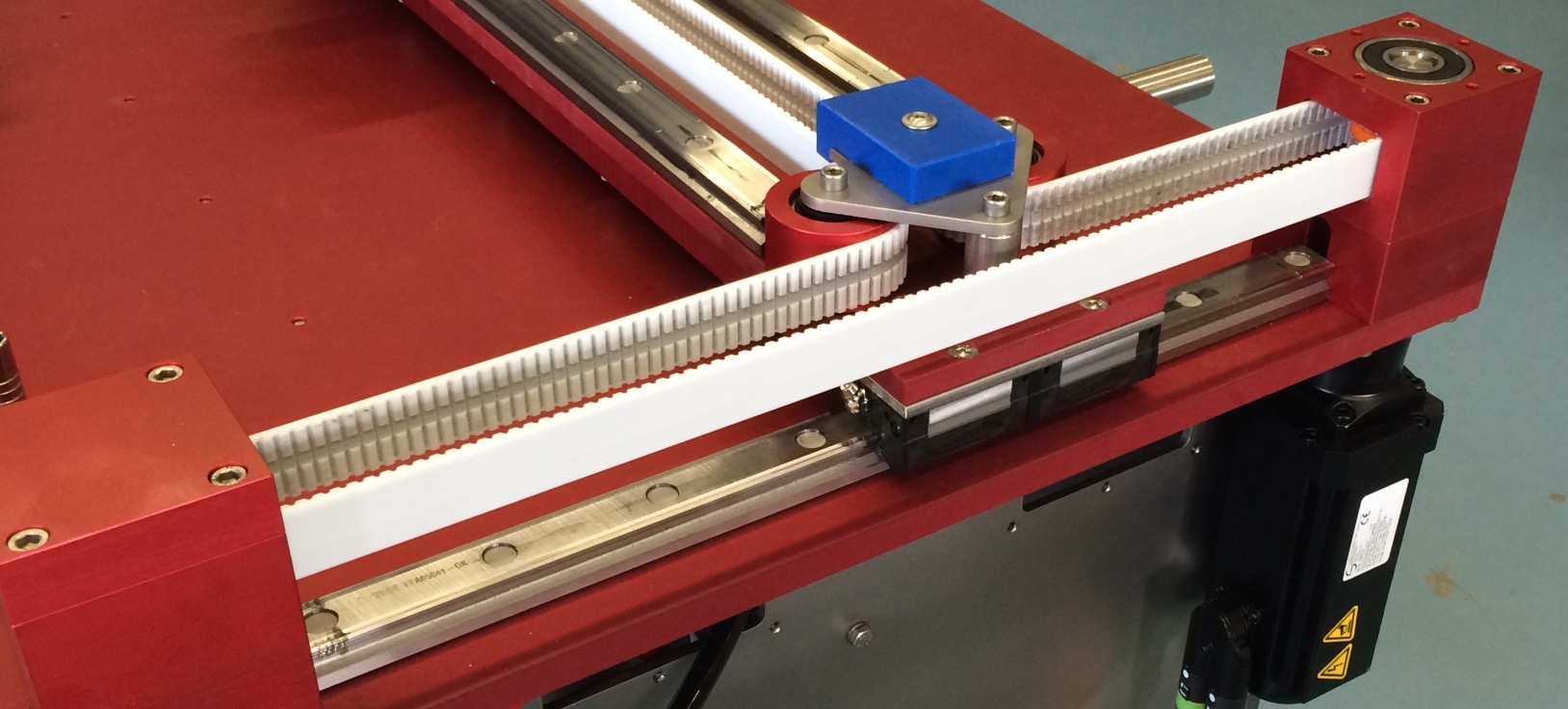

The machine is equipped with 9 pieces Stober servo drives with EZ servo motors and SD6 servo controllers equipped with EtherCAT. A unique feature is the fast feeding of the tube with the HPR racks and P-EZ planetary servogears with ZV pinion.

Conducted by the project team of ATB Automation.

A system composed of XYZ HSB Delta-S linear units with spindle and Stöber EZ-servo motor (X and Z-axis) and HSB-Beta Z linear unit with a toothed belt and Stöber PE-EZ planetary servo motor gear. The system is able to move gas cylinders of 20 kg within a reach of 1000 x 300 x 1000 mm, without external guides.

Central control is the Trio MC4 controller with Delphi communication via OCX commands. The Trio controller controls the Stöber SD6 drives via EtherCAT.

Single belt gantry system in the bakery industry: positioning of a spray installation.

Stober servo system with Trio Motion Controller

The servo system and the control system is provided by ATB Automation. This consists of:

- Stober planetary servo drive, PE-EZ

- Stober servo controller SD6 with EtherCAT

- Trio Motion Controller MC4N with EtherCAT

- Trio digital / analog inputs and outputs

- Trio 7 "Touchscreen, UNIPLAY

Programming and commissioning project team of ATB Automation

In cooperation with the producer of the spray system the Trio MC4N Motion Controller is programmed by ATB Automation.

- Motion software with a gantry coordinate transformation, which makes the positioning easy in X and Y (mm) can be programmed

- PLC functionality programmed in IEC 61131

- Operating software in the control panel

The tuning of the servo system is performed by the specialists of ATB Automation.

This is all conducted according to an advance down project design and planning with a fixed price agreement.

ATB Automation: More than components

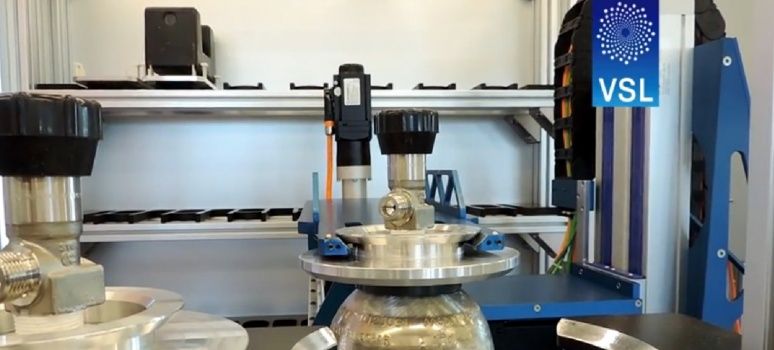

A system with durable electric actuators from the GSX-series of Exlar which ensures that the quality if a bicycle frame is determined by tests on stiffness and elasticity. These compact roller screw servo actuators are very powerful, reliable and have a high life time.

The actuator has a payload of 10 kg and moves with 3,5 Hz. The actuator is controlled with the Stöber SD6 controller via EtherCAT.

A machine for testing vacuum cleaners where the handle is being moved back and forth at a high frequency (36 beats per minute) over a length of 1 meter. The friction and angle of the movement can be adjusted to simulate all situations. For the linear movement a compact Beta-S lineare module from HSB is being used, suitable for heavy-duty systems and high-speed applications.

The HSB Beta is a closed linear unit with a spindle transmission which is neatly finished with cover band.

For the position, a Stöber servo motor is used from the EZ-series in combination with the fast and accurate Stöber SD6 digital servo controller.

The software engineers at ATB Automation assist in programming and commissioning via the help desk or on site

Besides control with I/O the drive can also be controlled with EtherCAT and ProfiNet.

The SD6 drive also has the CANopen option available.

This controller can be controlled with a display via Modbus, Profinet or EtherCAT. Click here for more information.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.