2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

Accurate and constructive interesting servo drive consisting of a servo motor from the EZ series, with directly mounted right-angle helical bevel gear unit from the STÖBER MGS series. Without adapter and coupling.

Right-angle helical bevel servo geared motors available as:

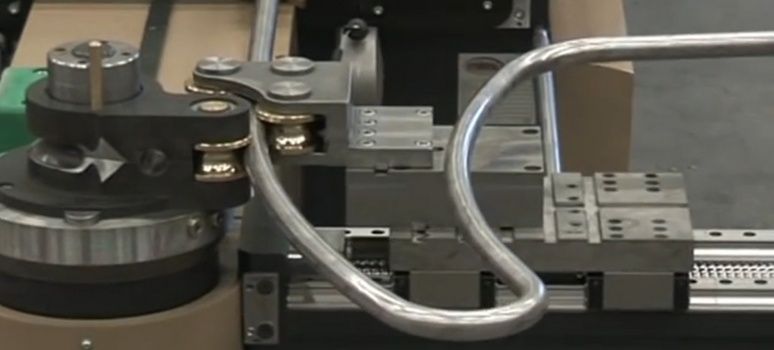

Bending machine for cold forming of tubes and profiles in draw bending operation, driven by Stöber servo drives.

Cardboard boxes are produced by folding continuously feeded cardboard with rotating hooks.

The Stöber P-EZ planetary servo drives are controlled by a motion controller. The hooks are positioned by a cam-profile.

Handling of 45,000 eggs per hour on a carousel which, through servo drives, rotates and with a lifting motion places the eggs in an egg braking machine.

Box packaging machine including feed with electronic and mechanical coupled drives. The feed consists of a smart-belt system with right-angle servo drives.

4-axis milling machine where a chisel with an integrated helical movement is positioned and thread is cut. The machine cut threads on location in old threaded holes.

With the Slitting machine glass fiber reinforced plastic can be cut. Hereby the rolls can be determined by both length and width.

Servo drives are used for the throughput of the material, positioning and turning the slit units. This way the production speed and the synchronous operation are fully matched to each other. The Stöber helical-bevel servo gear units were chosen because of their compact installation and hollow mounting shafts.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.