2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

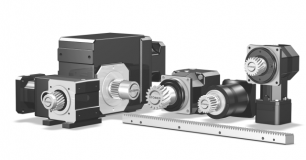

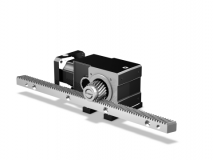

Compact systems with pinion directly mounted on the gearbox for rack and pinion drives. Suitable for robots and handlingsystems.

For gear units in the Stöber series:

PE / P / PA / PK / PKX / PE / KS / K / KL, modules 2, 3 and 4.

Spur and spiral toothing.

Force: 5 – 17 kN.

Zero backlash shaft hub connection (shrink glued and connected via feather key).

Highly accurate gantry system composed by two pieces rack-drive for the X-axis and one piece for the Y-axis. On the y-axis multiple welding torches can be mounted.

The servo drives are equipped with a Stober high precision planetary gear from the low clearance P serie. This gear unit has a backlash of1 arcminute. Stöber supplies the gear box mounted with pinion with helical gearing resulting in an accuracy of 10 microns. The gearboxes are lubricated for life.

Flexible programmable 4-axis palletizer robot. Heart in this application is the Trio Motion Controller where the 4 axis robot with 4 Leadshine servo drives is controlled via a coordinate transformation. The fast EtherCAT connection between the Trio MC4N-ECAT controller and the drives ensures accurate and simple communication. In addition to the Trio Motion Controller, mechanical components are also used, such as a slewing ring bearing for the rotation movement and a rack and pinion for the horizontal movement. Each servo shaft is equipped with a Stöber planetary gearbox or angle worm gearbox.

A multi radius bending machine for products with multiple radii as well with different diameters, time-saving must be achieved by bending in one single cycle. Some examples are tubes for furniture and automotive.

Fully servo driven machine to achieve the highest performance:

- Pipe diameters up to 25 mm with a thickness of 2.5 mm

- Bending moment 1000 Nm

- Clamping force 25 kN

- Bending speed 540 deg / s

- Feed speed of 2100 mm / s

- Rotation speed 720 degrees / s

The machine is equipped with 9 pieces Stober servo drives with EZ servo motors and SD6 servo controllers equipped with EtherCAT. A unique feature is the fast feeding of the tube with the HPR racks and P-EZ planetary servogears with ZV pinion.

Innovative design rack and pinion drives with supporting bearing cover permanently bolted in place. For applications in machine manufacture, automation and robotics.

More information about rack and pinion drives.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.