2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

Date: 18 September 2023

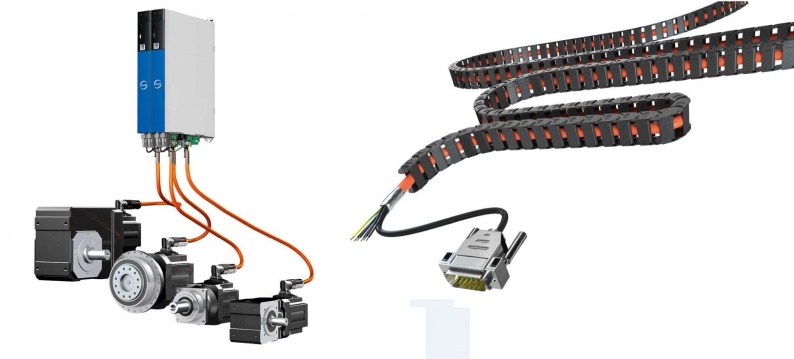

STOBER has further advanced its One Cable Solution (OCS) in collaboration with encoder manufacturer HEIDENHAIN, bringing the next generation to the market. Thanks to the future-proof HEIDENHAIN EnDat® 3 protocol, the new hybrid cable can reliably connect motors and drive controllers at a distance of up to 100 meters. The user receives a complete system consisting of synchronous servo motor, cable and the appropriate drive controller. One of the leading figures behind this development is Dr. Florian Dreher, Head of Development (CTO) at the Pforzheim-based drive specialist.

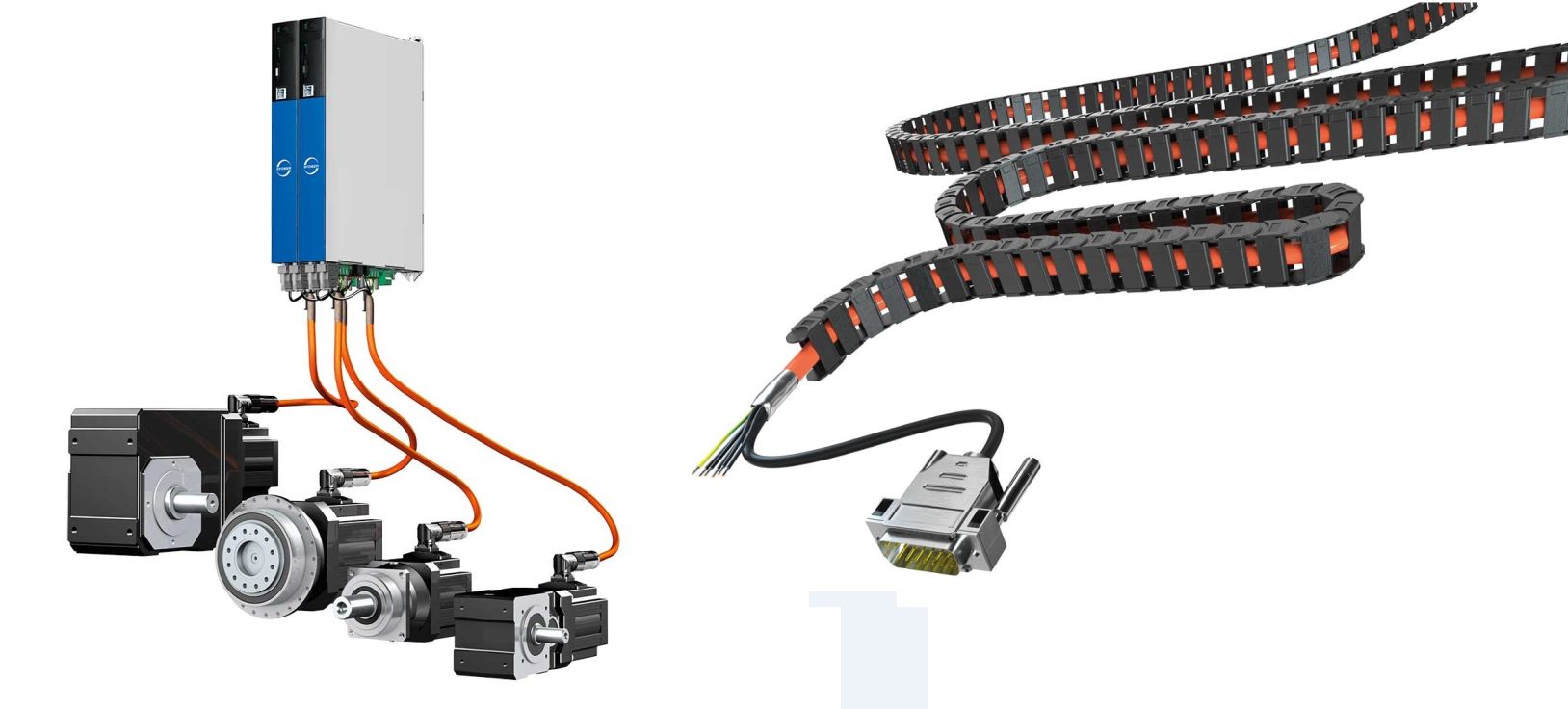

Pforzheim-based drive specialist STOBER has been offering the One Cable Solution—or OCS for short—since 2016. While a conventional solution has one cable that transmits the encoder data and another that carries the electrical power, there is one hybrid cable with OCS that handles both tasks. Until now, there have been minor weak points: If encoders and drive controllers are spaced more than 15 meters apart, data can no longer be transmitted without faults in all cases. In that case, an output choke is needed for each cable. A choke is expensive and takes up extra space in the control cabinet. “We have solved these problems in cooperation with HEIDENHAIN,” Dr. Dreher explains. “To do this, we further developed the existing STOBER one-cable solution and optimized it specifically for highly dynamic applications in drag chains.” As Head of Development and Purchasing for Motors, he was instrumental in this.

Dr. Dreher has been working at STOBER since 2017 and studied mechanical engineering in Karlsruhe. Even then, he had a strong liking for electrical engineering. “I really like both fields, and at that time, unfortunately, the major in Mechatronics did not yet exist,” he says regretfully. After graduating, he began working at a large drive technology manufacturer and earned his doctorate by studying part-time in addition to working. His research project concerned the design of electrical machines. Why did he make the switch to STOBER? “My former employer is also family-run, but simply too big. I was one of many,” he explains.

At the Pforzheim-based drive specialist, he values the product range, which he finds very interesting. “We develop all components in-house. These include motors and gear units on the one hand, and cables on the other,” he says. “The company is streamlined, the hierarchies are flat and there is excellent communication with other departments such as Gear Unit Design and Electronics. In addition, we are globally active. For some years now, we have been increasing our focus on the Asian and North American markets.” In addition, STOBER is also a family-owned company. This has a positive impact on our collaboration.

For STOBER, it goes without saying that we have our eye on the competition and always compete on an equal footing. “Nevertheless, we are also often one of the trendsetters, as with the development of our OCS.” In cooperation with the manufacturer of the new hybrid cables, STOBER subjected them to numerous lab tests. Even after five million cycles, the quality of the data transmission is good enough that all signals could be read and evaluated flawlessly without errors in the encoder communication, even at a cable length of 50 meters without a choke. “We did have some obstacles to overcome in the beginning,” Dr. Florian Dreher says. But the lessons learned from this were enormous. Comparable cables from other providers fail here in the standard version. The second OCS generation from STOBER, on the other hand, does not.

As project manager, Dr. Dreher was responsible for the cable design and production, interference resistance and test coordination. “Most competitors would conduct separate tests on the individual components that play a critical role in the flawless function of the OCS,” says Dr. Florian Dreher. “By contrast, our test focused on how they work together.” For the department head, this was also the most important insight.

“We must always have an eye on the system.” This includes cable, motor, encoder and drive controller. This meant that each relevant specialist department had to be involved in the project. Therefore, it was very important to have good communication with each other, particularly with development partner HEIDENHAIN and STOBER’s Electronics Development department. This also included the manufacturer of the hybrid cables, which also provided the drag chain system for the tests. The experience that Dreher took away from the OCS project is that teamwork is enormously important and paves the way to maximum success.

What will happen now with OCS? Dr. Florian Dreher pauses briefly to consider, then says, “We want to clarify the added value for our existing and potential customers. Many users on the market still see us as one among many in this area. But we aren’t.” The fact is that the OCS system, composed of geared motors, cables and electronics, ran in a field test around the clock for over half a year without faults. In addition, the components included in the system can each be connected with just a click.

Are there plans for the future? “We will continue making technical improvements to motors and cables,” Dr. Florian Dreher promises. “This involves taking the most finely tuned STOBER system and advancing it even further. Because this is exactly what our success factor is.” Dr. Dreher also shares responsibility for determining the direction of future developments and coordinating the individual departments to that end. As the unifying head, he’s on top of it.

Dr. Florian Dreher is CTO at STOBER and has been working at STOBER since 2017. Since March 2023 Dr. Florian Dreher is member of the managing board.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.