2024

NEW: Flex-7 - Flexible Machine Controller

The Flex-7 is Trio’s high performance, compact Flexible Machine Controller. Offering 128 axes of motion via EtherCAT, with update rates down to...

Trio Motion Technology, headquartered in Tewkesbury (UK) and founded in 1987, develops hardware and software for high-quality motion controllers for the control servo and stepper motors. Since 2001 Trio Motion Technology is an important partner and supplier of ATB Automation. In many solutions from ATB Automation and its customers, a Trio motion controller is the heart of the solution

Trio Motion Technology was founded in 1987 and has since grown into a leading specialist in the field of high performance motion control technology.

Developer and producer of high-quality motion controllers for flexible and economical motion control solutions. Used worldwide for control of complex high dynamic automation and machine control in most industries.

Since 2017 Trio Motion Technology is part of Estun Automation, manufacturer of servo drives and robots from Nanjing (China).

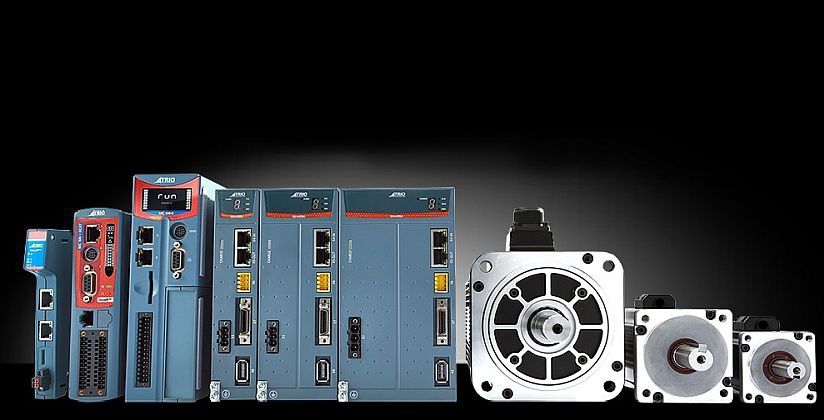

As a result, within a few year Trio Motion Technology's delivery program has grown into total solutions with servo controllers, servo motors and scara robots.

Trio Motion Technology is represented worldwide with offices in Tewkesbury (UK), Pittsburgh (US), Pune (India) and Shanghai (China) and through a network of more than 100 fully supported distributors.

Trio has its own research & development team that develops controls as solutions for customer applications. Trio has introduced many innovations to the market over the years. All products have been tested to international standards and the company has ISO9001: 2015 quality approval.

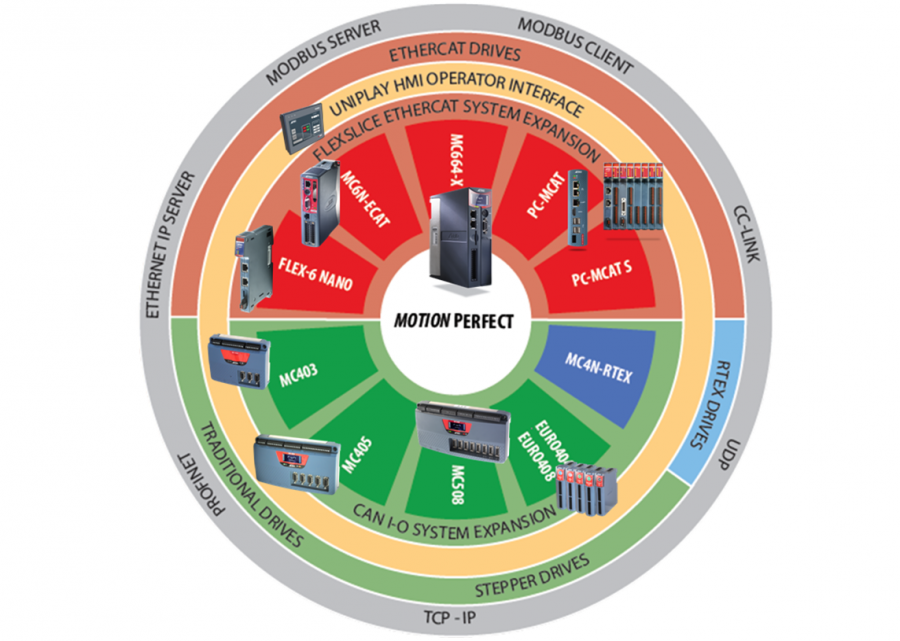

Trio Motion Technology Motion Coordinators, extension modules, I/O modules, EtherCAT controllers and HMIs are designed to control motion in industrial machines with a minimum of external components. In many applications, Trio's hard and software products can be combined to build a control system for machines with multiple axes and peripherals.

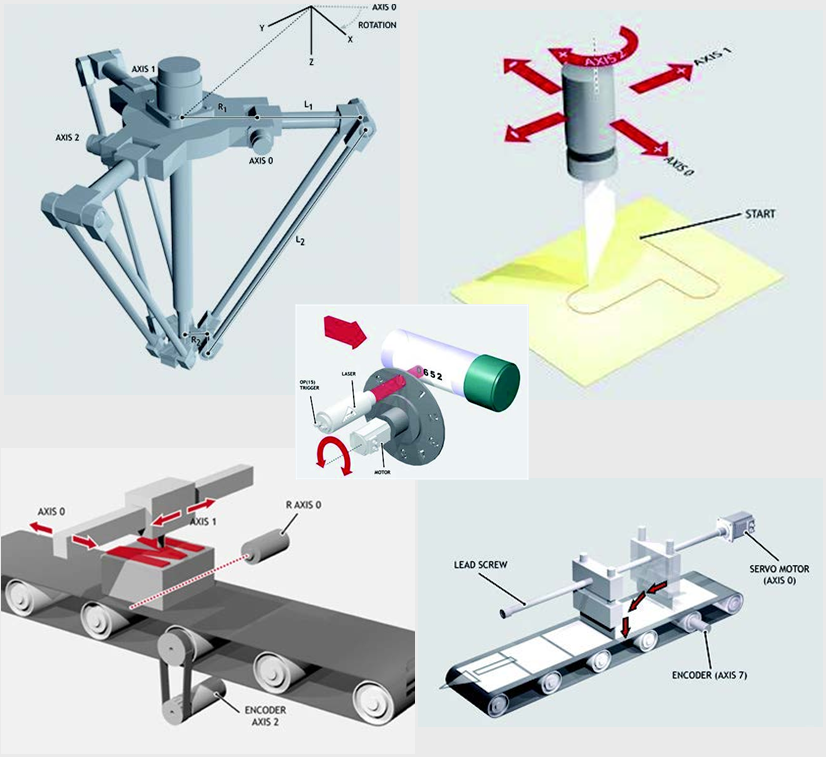

With an extensive set of move functions for coordinating single or multiple axes, complex motion control applications become manageable. Functions include linear, circular and spherical interpolation as well as cam profiles and easy electronic coupling of axes. In addition, there are position registration functions with fast inputs and switching of outputs on a position range of one or more axes.

Motion profiles from CAD / CAM systems are made possible with the Look-Ahead functions in the Motion Coordinators. Polyline data is buffered and processed in an intelligent way to ensure constant speed for dispensing applications or angular speed control for cutting.

The MC4 / 5/6 series Motion Coordinators open up a new world of robotics and frame transformations. Delta systems of 2 or 3 axes are programmed in the familiar Cartesian coordinate system while the complex position transformation calculations are provided by the Motion Coordinator. Transformations for scara robots up to 4 axes and articulated arm robots up to 6 axes are also supported.

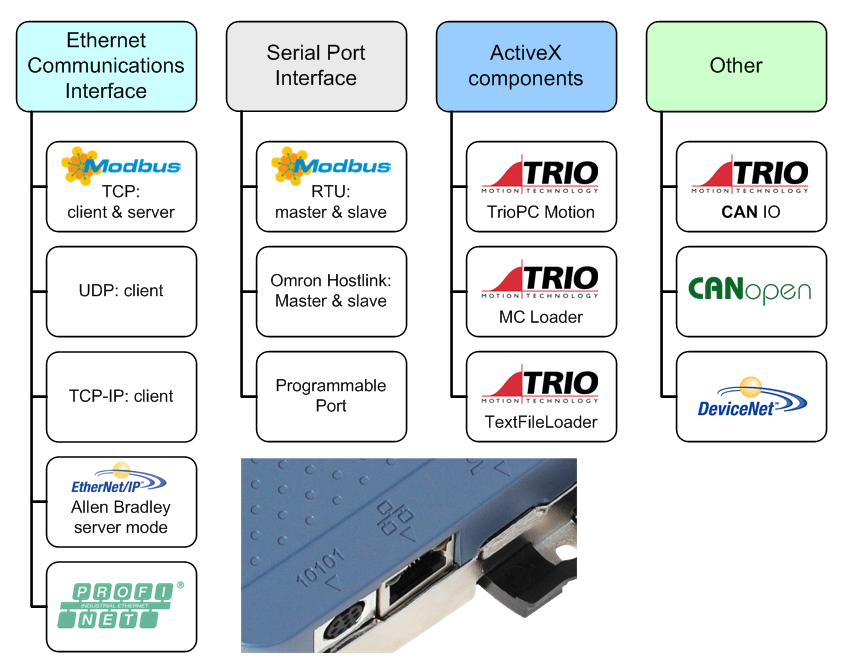

The Trio Motion Coordinators are extremely modular, so that the user can tailor them to their specific application. Systems can be used stand-alone, but also have the flexibility of communicating with external PCs or other overhead controls. In addition to the digital and analog IO expansion via CAN or EtherCAT, the most common factory communication protocols are available on the Motion Coordinators.

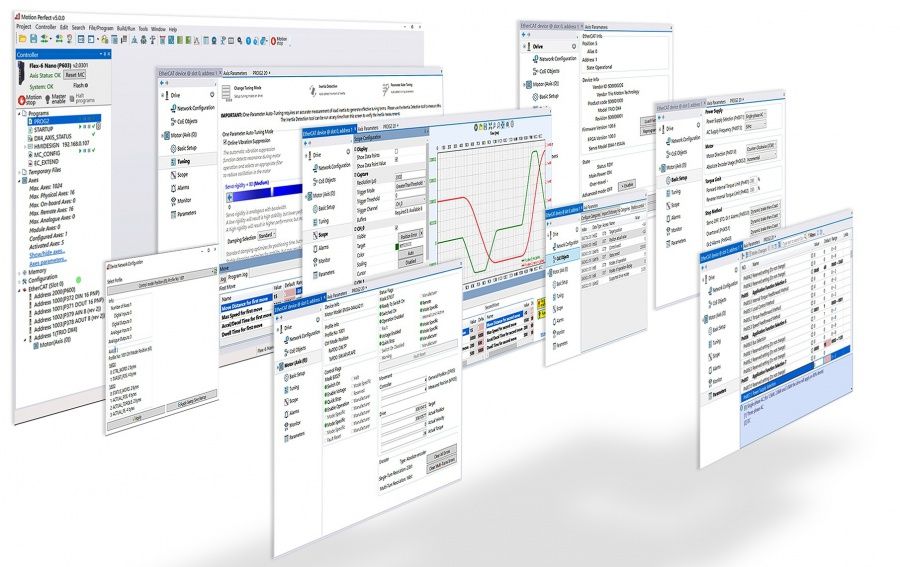

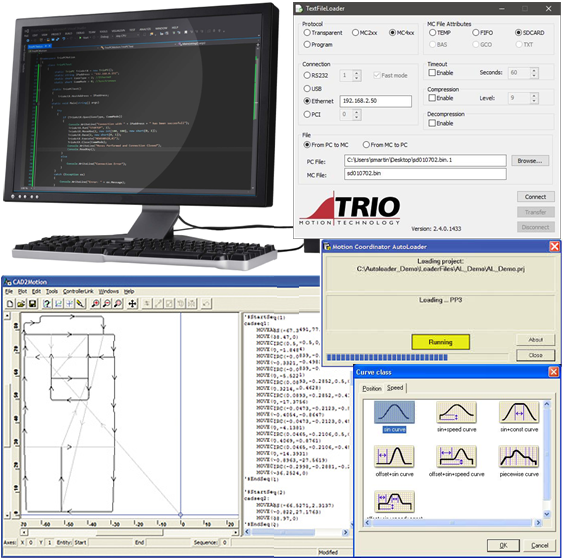

Motion Perfect is the development environment for the Trio Motion Coordinators range including the new Flex-6 Nano and MC6N-ECAT. It offers the user an easy-to-understand Windows-based interface for rapid application development, controller configuration and motion and controller function monitoring. In addition to the Trio MOTION-iX programming language, supported IEC languages and editor for HMI pages are available.

MotionPerfect also has an MC400 simulator and Uniplay HMI Simulator program for offline programming. And a 3D oscilloscope and 3D visualization tool to visualize the results.

Trio has developed a series of powerful software tools for use with every Motion Coordinator. These tools offer all the functions required for setting up, programming, generating Cam profiles, robot control and CAD position trajectory conversion with minimal development time.

CAD2Motion is a program designed to enable users to translate CAD-generated two-dimensional motion paths into Trio MOTION-iX programs.

PCMotion ActiveX can be used in any programming language that supports ActiveX (OCX) components, such as one of the Microsoft Visual languages (BASIC, C #, C ++, etc.), LabView, Delphi, etc.

With the help of the TextFileLoader (.txt) files can easily be loaded in the memory of the controller or the SD card (if present). For example, G code and HPGL files can be processed on the controller using sample programs available through ATB Automation.

Trio has been developing and supplying servo controllers and servo motors since 2021 in collaboration with parent company Estun Automation.

The Trio servo systems are designed to work seamlessly with Trio's EtherCAT controllers and be fully integrated into Trio’s application development tool, Motion Perfect allowing complete machine configuration from one tool; commissioning, diagnostics and programming.

Trio provides total solutions with the Trio EtherCAT motion controllers for central control of up to 128 servo drives and servo motors.

Trio supplies Scara Robots with an arm of 400 to 700 mm. These are controlled with a Trio of motion controllers.

An integrated solution with robot and machine control as one coordinated system maximizes performance and simplifies programming and possible future expansion of the system.

Motion Perfect includes access to IEC 61131 and PLCopen and the robotics solution; TrioRPS.

This allows advanced visualization including a 3D oscilloscope.

ATB Automation regularly organizes Motion Application Days to get acquainted with the controls of Trio Motion Technology. These days are free to visit.

During this information day an explanation is given about the possibilities and method of programming.

Look at the ATB Automation agenda items for more information and the data of the Trio Motion Control information days.

ATB Automation organizes introductory training courses to support customers when they get started with the Trio Motion Controllers. This training is given by Trio trained application engineers with a lot of practical experience. The basis for the introduction training is the ATB Automation Template.

This training can be supplemented with in-depth knowledge sessions on specific items such as IEC61131 programming, robotics and motion control with vision sensor.

For more information read here.

The Flex-7 is Trio’s high performance, compact Flexible Machine Controller. Offering 128 axes of motion via EtherCAT, with update rates down to...

Vision, Robotics & Motion is the trade fair in the Benelux in the field of automating production processes. This year we were again present at this...

The EtherCAT Technology Group keeps EtherCAT technology open to all potential users. It brings together manufacturers of EtherCAT equipment,...

New SCARA robot range provides OEMs with integrated control solution for robot, motion and machine automation The motion-first automation control...

The company Wadcon Automation, located in Groningen, specializes in the construction of special machines for the automation industry. From one of her...

The company AME in Eindhoven makes various products for various customers. The volumes of the products are such that with a sufficient degree of...

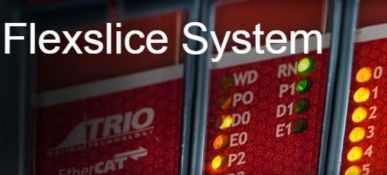

The EtherCAT Flexslice System is designed to let you do more! It offers fast flexible expansion for motion applications and can be used with Trio or...

Trio’s PC-MCAT 64 is an innovative "Motion + PC Solution". A powerful quad core Intel Atom processor is used to drive both a high performance...

On February 5, Dynacon Industrial Limited, a wholly-owned subsidiary of Estun Automation, acquired 100% of the shareholdings of TRIO Motion...

On Wednesday 7 and Thursday 8 June 2023, we were present at the Vision, Robotics & Motion trade fair in the Brabanthallen in...

The EtherCAT Technology Days took place on 11 and 12 April 2023, right in the technological heart of Twente and Eindhoven. Participants learned all...

Since October 2020 I am doing an internship at ATB Automation. My name is Louk Jägers, I am 20 years old and I live in Mijdrecht. In my spare time I...

Location Netherlands

Vermogenweg 109

NL-3641 SR MIJDRECHT

THE NETHERLANDS

Contact information:

Tel +31 297 28 58 21

Location Belgium

Bergensesteenweg 106A - bus 2

B-1600 SINT-PIETERS-LEEUW

BELGIUM

Contact information:

Tel. +32 2 588 80 05

Benelux

ATB Automation

Vermogenweg 109

NL-3641 SR MIJDRECHT

NETHERLANDS

Benelux

VAT NL 003226591B01

Chamber of Commerce 30100549

IBAN NL93 HAND 0784 5271 80

BIC HANDNL2A

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.