2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

Date: 22 January 2021

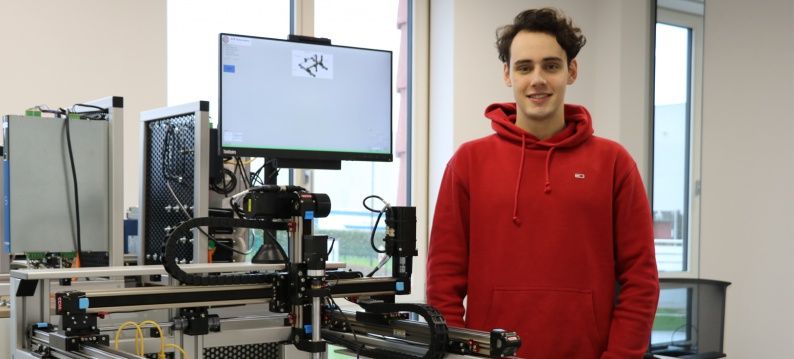

Since October 2020 I am doing an internship at ATB Automation. My name is Louk Jägers, I am 20 years old and I live in Mijdrecht. In my spare time I often meet up with my friends or I am playing sports or gaming. Currently I am following the Mechatronics Engineering study level 4 at the MBO college in Hilversum. For this study it is necessary to do an internship, this internship is also called a ‘Test of Competence’.

For an internship company I started surfing on the Internet and saw ATB Automation pass by. I began reading the website and my interest was aroused because of the industry, the product range and the different techniques that are used. With the application letter that ATB received, I was soon invited for an interview. The speed of communication gave me a good impression of the company, they are serious and motivated. I really like this in a company and it is also one of the reasons I chose ATB Automation to do my internship.

The assignment

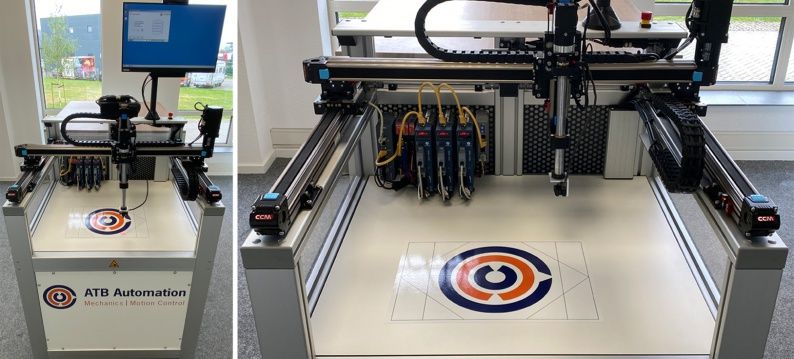

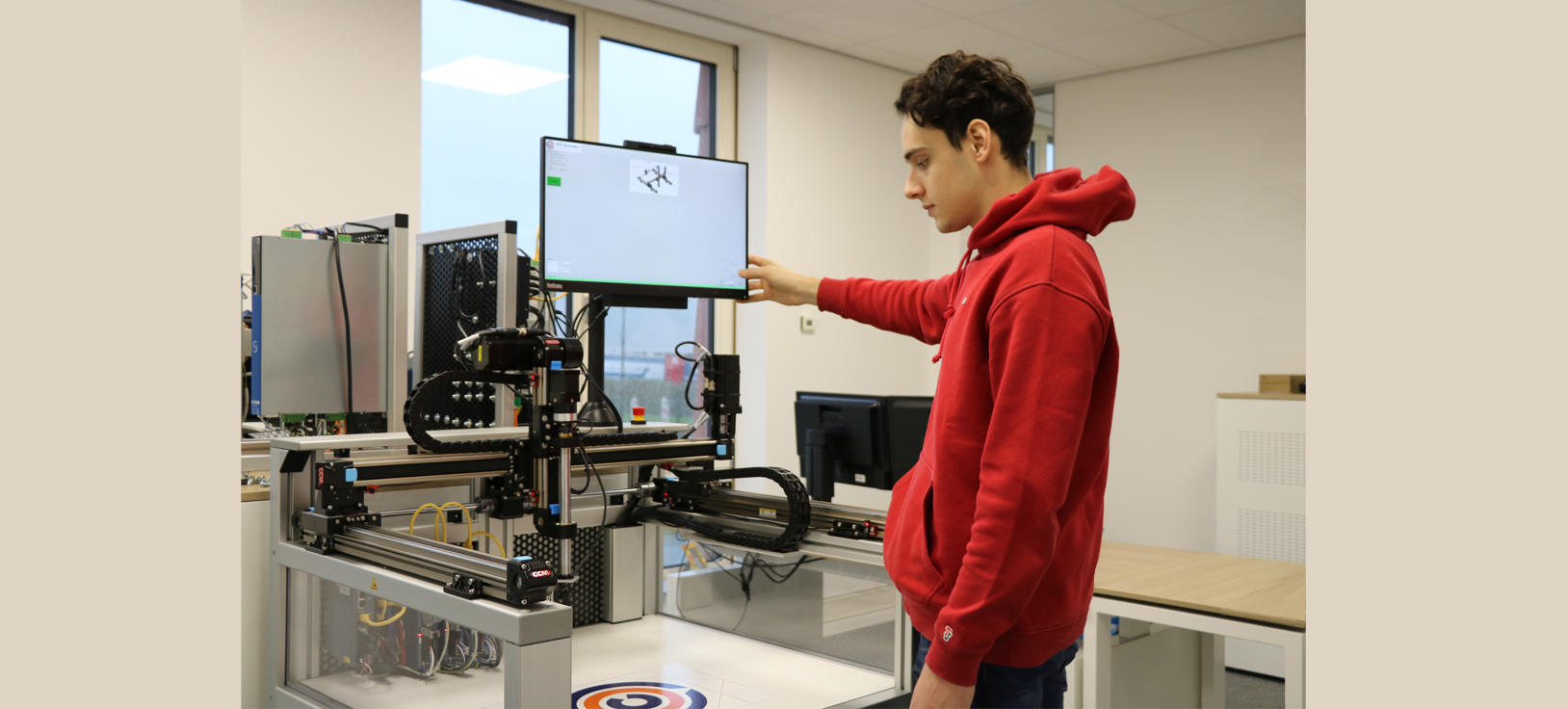

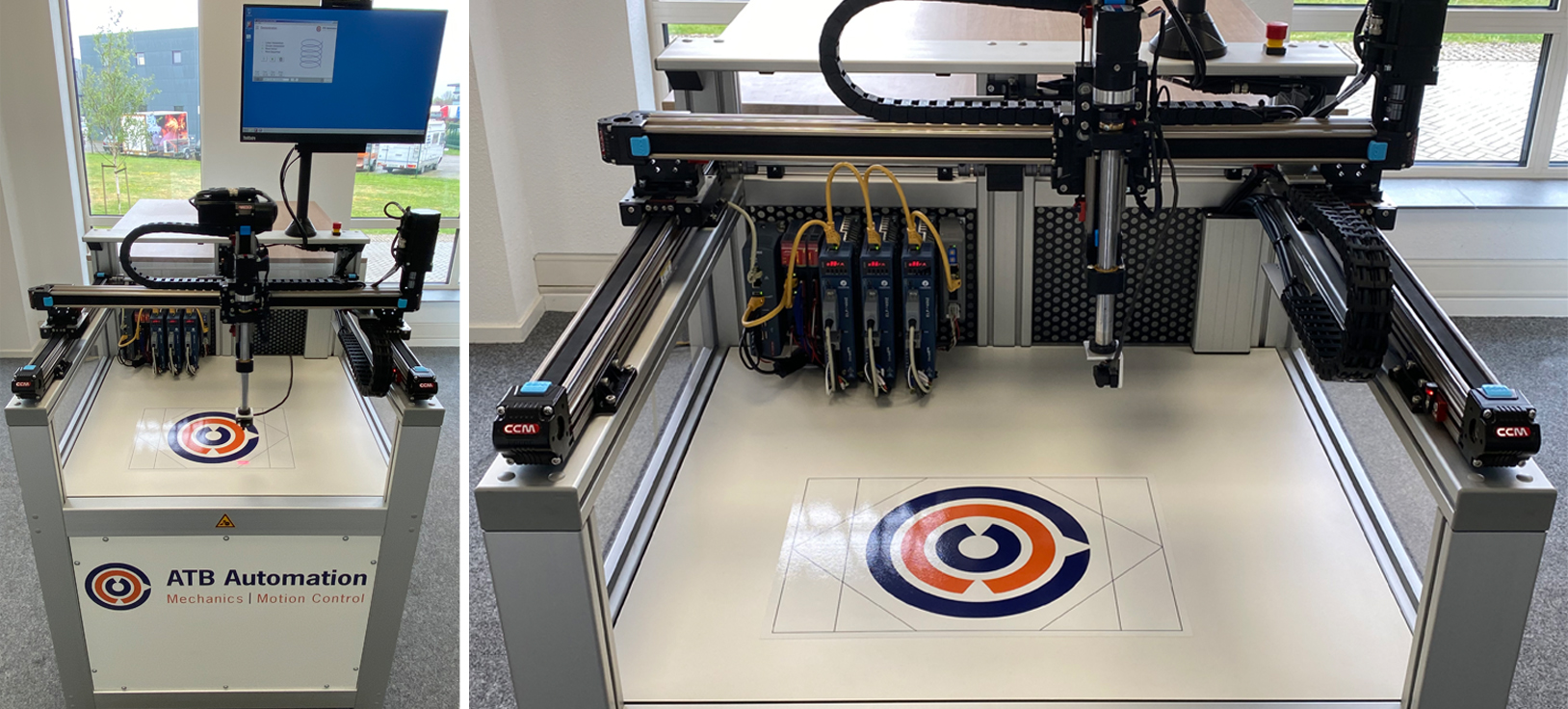

From ATB Automation I got the assignment to design the machine operation of a 4D robot in which the brands Trio, Leadshine and CCM are represented. I wrote and programmed an operating program fora n HMI (Human Machine Interface). With this operating program the operator can, for example, refer the robot to its home position and then perform various ineterpolatng movements.

The approach

To write a control program, I first had to learn more about the 4D robot that was already developed at ATB Automation for trade shows. This 4D robot consists of an XYZ system with lineair axes and a 4th rotation axis on the vertical Z axis. I’ve done reversed engineering. This means researching the robot to learn everythin about the components used and getting to know the robot this way. Once I knew with what I was working, I could start programming the robot.

The challenges

Programming was a real challenge. This was a bit new to me and we did not pay much attention tot his at school. I learned to program at ATB Automation. This was very productive. I was writing codes all day and trying new things.

Sometimes it was quite difficult. By asking a lot to the application engineers at ATB Automation and searching for information on the Internet, it all worked out. In the end, with enough support and selfstudy I was able to write a program that works for the 4D robot.

Lots of learning

I have now reached the end of my internship. Ot was a very fun and educational internship! I learned a lot about engines, programming, operating systmes and the forces involved.

What I liked most about my internship was the moment I had written of adapted a new program, it also worked on the robot. It was very nice to see that there was immediate movement at the 4D robot as conceived. This also kept the fun in programming.

About ATB

During my internship I got a lot of help with my project. If I couldn’t find a way or didn’t know where to find the information, I could always ask for help and I was getting helped on my way. I would like to thank my colleagues, especially my internship supervisor Karel Keers. He and the other ATB colleagues helped me a lot during my internship.

Due to the Corona time, I had less contact with my colleagues. A lot went online, but this didn’t make it any less fun. We could all get along very well and it was always very pleasant.

‘ATB Automation is a fun company to do an internship.’

From ATB Automation I got the opportunity to orientate myself further with the potential to work at ATB Automation.

‘I’m glad I got this opportunity. It is a very pleasant, enthusiastic and motivated team to work with!’

The motion control system of robot is usually composed of <a href='https://okmarts.com/catalogsearch/result/?q=motor' target='_blank'>motor</a>controller, motor drive and motor body (mostly servo motor). The motor controller has intelligent operation function and can transmit instructions to drive the motor. The drive can provide boost current to drive the motor according to the command of the controller. The motor can move the robot directly, or make the robot move through the transmission system or chain system.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.