2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

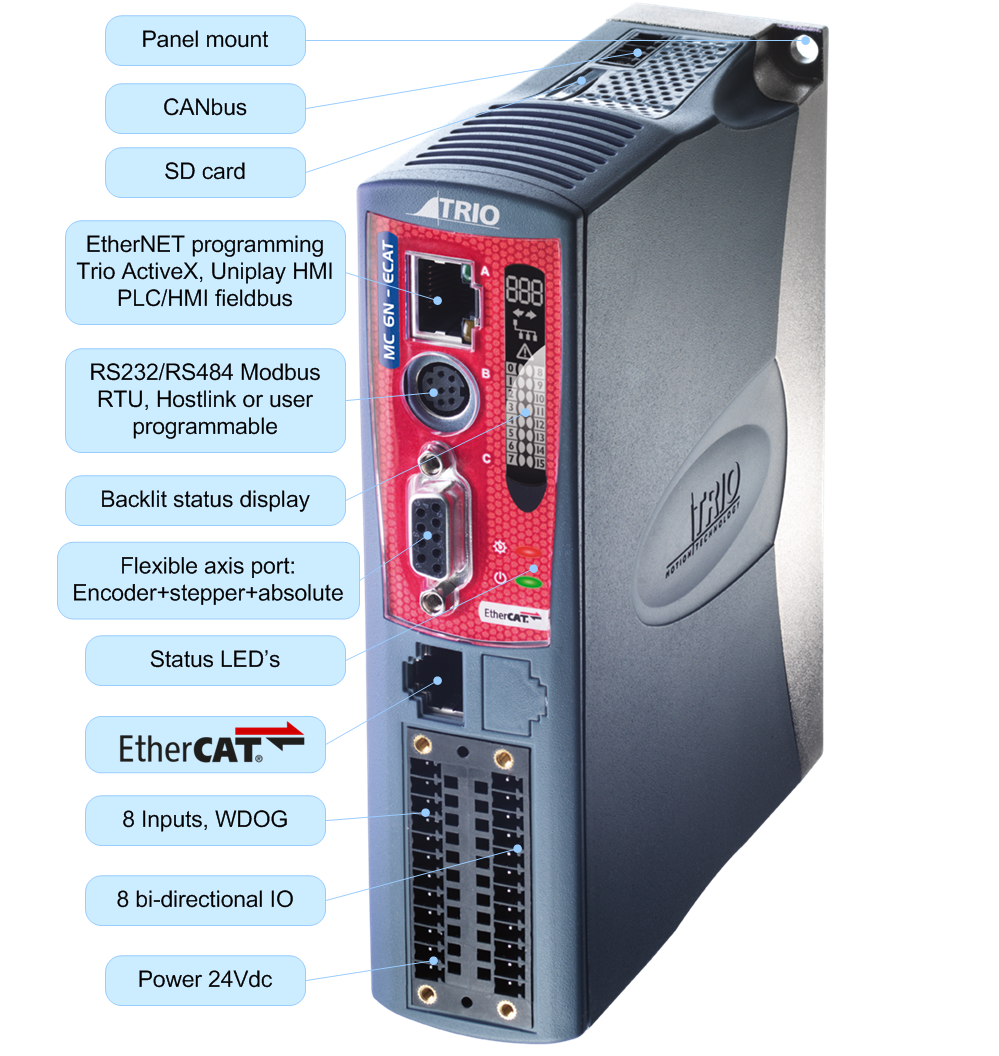

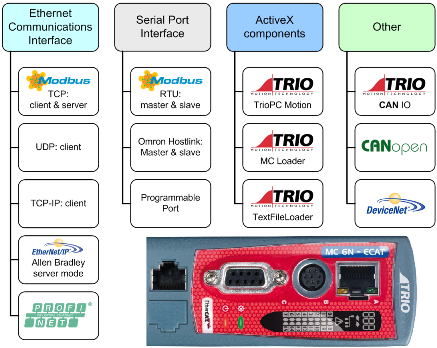

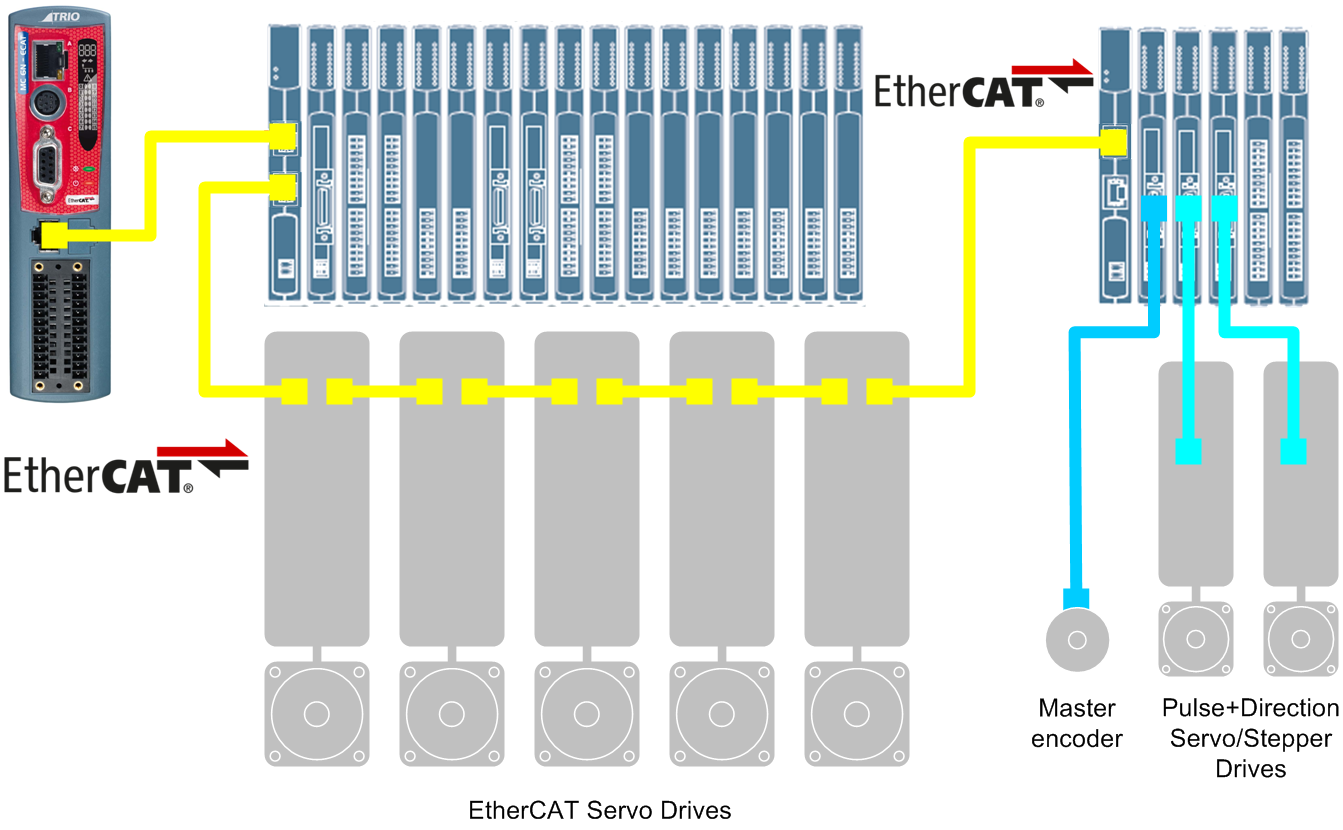

The MC6N is a powerful, flexible and compact motion controller. This fast EtherCAT Master can control up to 64 EtherCAT servo or step controllers as a stand-alone controller and is thereby equipped as standard with a conventional encoder or stepper port (flexible axis), 8 binary inputs (including 4 position registration inputs) and 8 bi-directional outputs. The MC6N can be connected to the Trio EtherCAT Flexslice system via the Flexslice EtherCAT Coupler for extra functionality. This allows the MC6N control to be expanded with additional binary and analog IO and / or conventional extra encoders, servo and stepper systems.

Versions of the MC6N are available for 2, 4, 8, 16, 32 and 64 motor axes. All versions are equipped with 64 software axes, each of which can be used as a virtual axis or via EtherCAT hardware-assigned axes. Each axis can be programmed with linear, circular or helical or spherical interpolation, electronic cams and coupled axes.

The built-in Ethernet port, serial port and CAN port make the Trio MC6N motion controller an extremely flexible motion controller for communication with other systems. In addition to programming the motion controller and the HMI connection, various protocols are available for communication with PC and PLC.

User programs can be written in Trio-based multi-tasking Trio MOTION-iX language using the powerful Motion Perfect application software for making complex motion easy. In addition, the standard IEC 61131-3 programming language is available, making fully functional PLC programming possible.

The Flexslice input / output modules from Trio offer a robust, fast and flexible solution for both motion control and general automation. EtherCAT cycle times of up to 125μsec are supported and the bus coupler uses EBUS technology to bring all submodules onto the EtherCAT network without degrading performance.

EtherCAT slave nodes (Flexslice modules) are connected via the Flexslice EBUS and the EtherCAT connector. Total number of slave nodes can be a maximum of 128 including I/O and more complex devices.

Flexslice modules:

Portal robot with a working range of 7600 x 400 x 2500 mm in the X-Y-Z plane where solar panels are stacked.

The HSB portal axes from the Gamma series with double guides are the basis of the system.

The X-Y-Z movements are performed with Trio servomotors and Wanshsin planetary gearboxes.

At the bottom of the Z axis is a 3D manipulator driven with the compact servo motors. The mass of the grab and the solar panel, a total of 75 kg, hangs on the Wanshsin planetary gearbox from the WAD series.

Interpolation of the 3D manipulator and the XYZ system is done with the Trio MC4N motion controller. The Estun servo controllers are controlled from the Trio control via EtherCAT control based. The Trio motion controller has been extended with a Touch Screen and additional I / O modules (Trio EtherCAT Flexslice system) for the complete machine control.

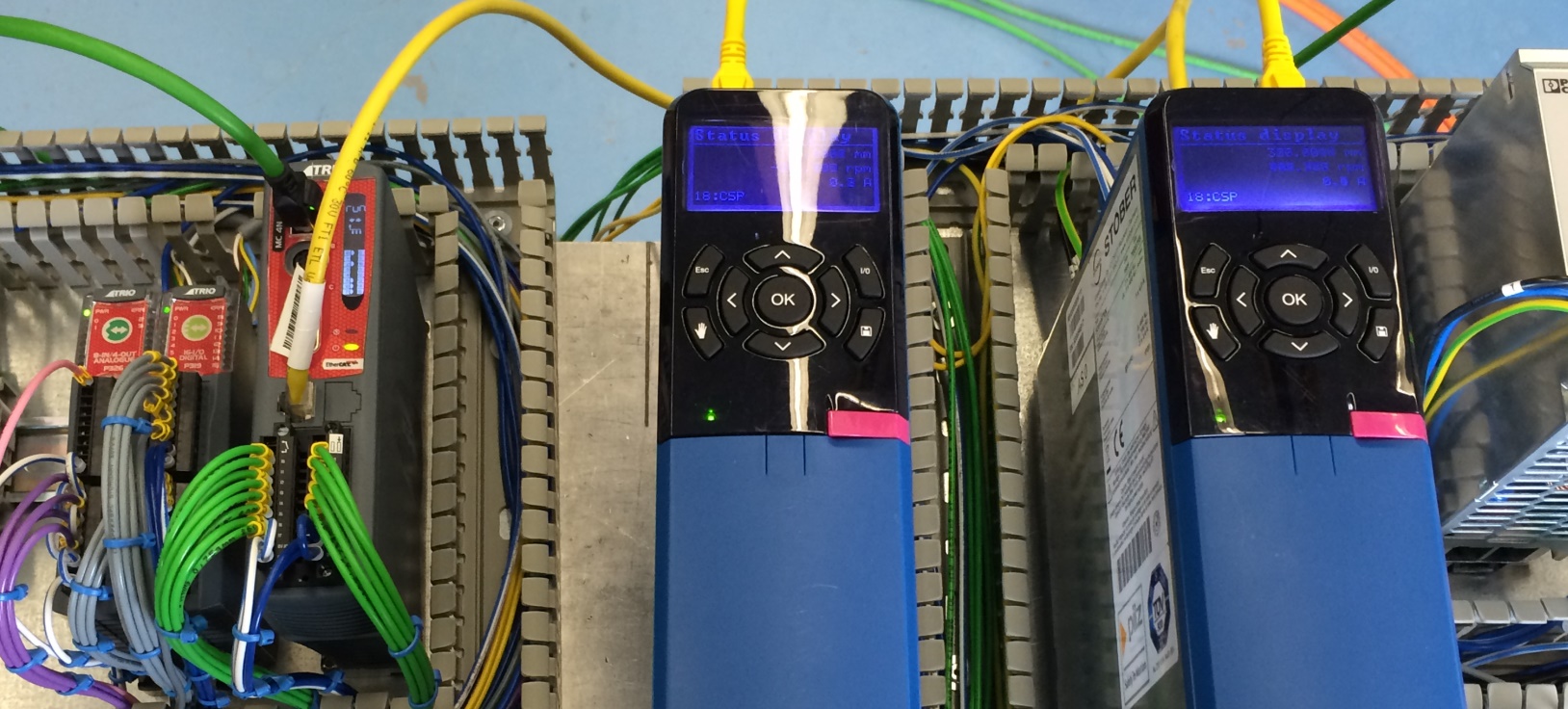

Flexible programmable 4-axis palletizer robot. Heart in this application is the Trio Motion Controller where the 4 axis robot with 4 Leadshine servo drives is controlled via a coordinate transformation. The fast EtherCAT connection between the Trio MC4N-ECAT controller and the drives ensures accurate and simple communication. In addition to the Trio Motion Controller, mechanical components are also used, such as a slewing ring bearing for the rotation movement and a rack and pinion for the horizontal movement. Each servo shaft is equipped with a Stöber planetary gearbox or angle worm gearbox.

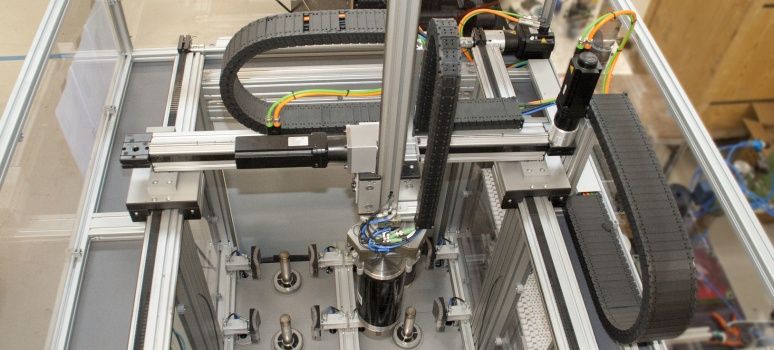

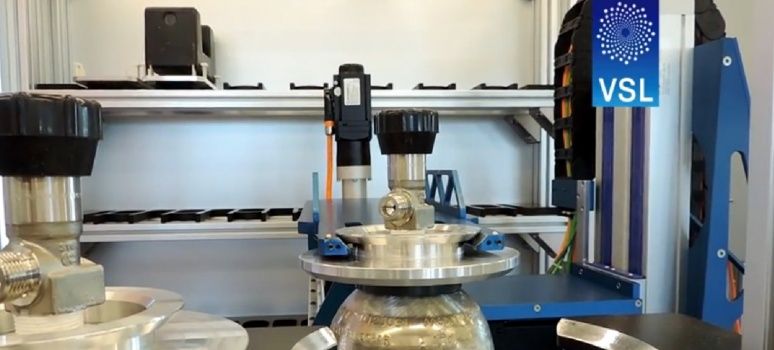

Compact Stöber planetary servo motor gears control an xyz system for handling isolation containers in a test machine. The XYZ system places the isolation container on one of the six test positions. After verification of the measurement system to the XYZ system picks up the container and place it on the rotator. Since the container is reversed by a fourth servo motor Stöber for the correct starting position for the next processing step.

The challenge in this system was the dynamic handling of a product with substantial mass of 25 kg, with speeds up to 2.5 m/s and accelerations of up to 5 m/s2. Using the calculations and the advices of ATB Automation a compact system is the result. The Stöber SD6 servodrives with EtherCAT in combination with Trio MC4N-ECAT motion controllers are easily and quickly connected and installed.

The standard STO safety card (Safe Torque Off) in the Stöber SD6 drives allows the integration of safety into the machine very easy. Safety of the operators is therefore guaranteed at all times.

Conducted by the project team of ATB Automation.

A system composed of XYZ HSB Delta-S linear units with spindle and Stöber EZ-servo motor (X and Z-axis) and HSB-Beta Z linear unit with a toothed belt and Stöber PE-EZ planetary servo motor gear. The system is able to move gas cylinders of 20 kg within a reach of 1000 x 300 x 1000 mm, without external guides.

Central control is the Trio MC4 controller with Delphi communication via OCX commands. The Trio controller controls the Stöber SD6 drives via EtherCAT.

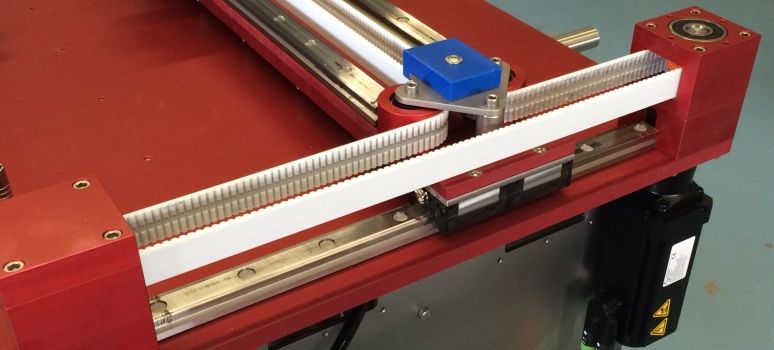

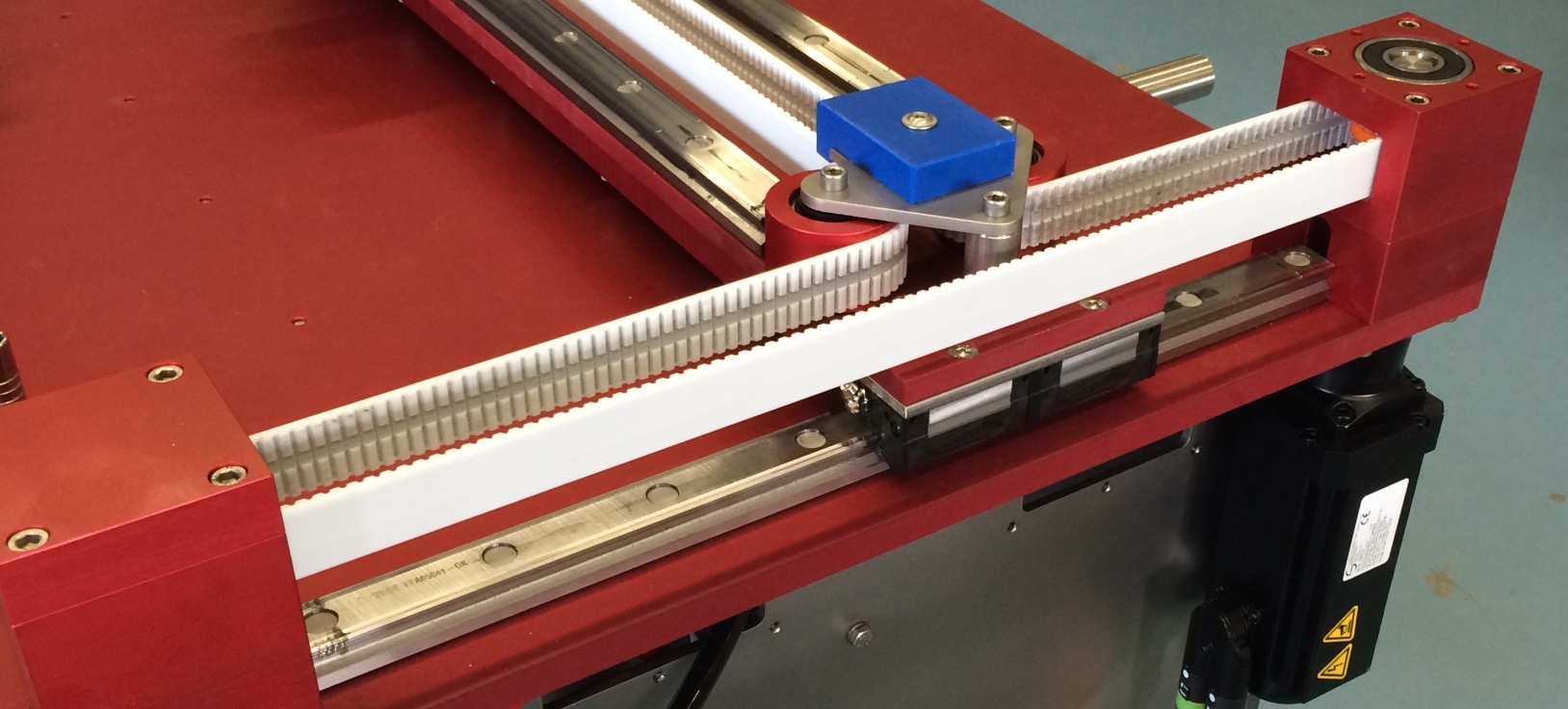

Single belt gantry system in the bakery industry: positioning of a spray installation.

Stober servo system with Trio Motion Controller

The servo system and the control system is provided by ATB Automation. This consists of:

- Stober planetary servo drive, PE-EZ

- Stober servo controller SD6 with EtherCAT

- Trio Motion Controller MC4N with EtherCAT

- Trio digital / analog inputs and outputs

- Trio 7 "Touchscreen, UNIPLAY

Programming and commissioning project team of ATB Automation

In cooperation with the producer of the spray system the Trio MC4N Motion Controller is programmed by ATB Automation.

- Motion software with a gantry coordinate transformation, which makes the positioning easy in X and Y (mm) can be programmed

- PLC functionality programmed in IEC 61131

- Operating software in the control panel

The tuning of the servo system is performed by the specialists of ATB Automation.

This is all conducted according to an advance down project design and planning with a fixed price agreement.

ATB Automation: More than components

A complete solution of ATB Automation has been used for cutting waffles.

Two servo driven lineair systems provide the input and output for plates of waffles. A third axis is used to print a cutting blade.

Central control is doe by the multi-axes Trio MC4N Motion Controller. The movements are recorded and matched in this controller. A Trio Uniplay display is being used for control. The Trio Motion Controller sends the servo drives real-time via the fast EtherCAT box.

The switchboard, programming and start-up of the system has been carried out by the ATB Automation project team.

The software engineers at ATB Automation assist in programming and commissioning via the help desk or on site

Besides control with I/O the drive can also be controlled with EtherCAT and ProfiNet.

The SD6 drive also has the CANopen option available.

CAM shapes, linked motion, linear, circular, helical and spherical interpolation.

Expandable with various I/O modules, displays and programmable with IEC 61131-3

ATB Automation supplies motion controllers from Trio Motion Technology and Leadshine. The Trio motion controllers can also be easily extended with various I / O and control panels so that the controller also can operate as stand-alone machine controller .

More information about motion controllers.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.