2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

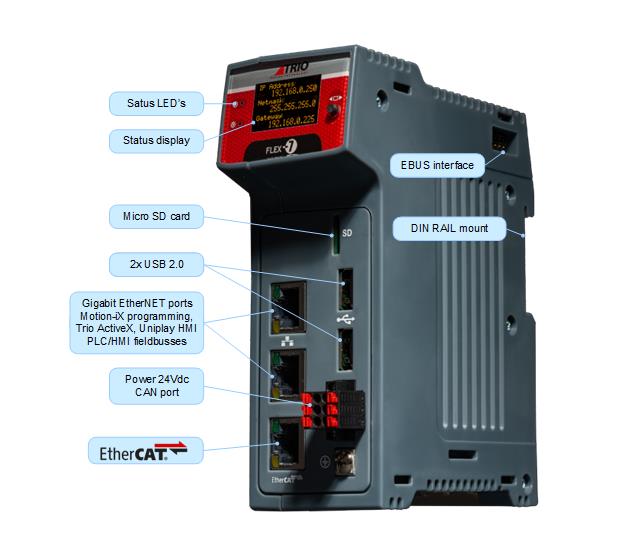

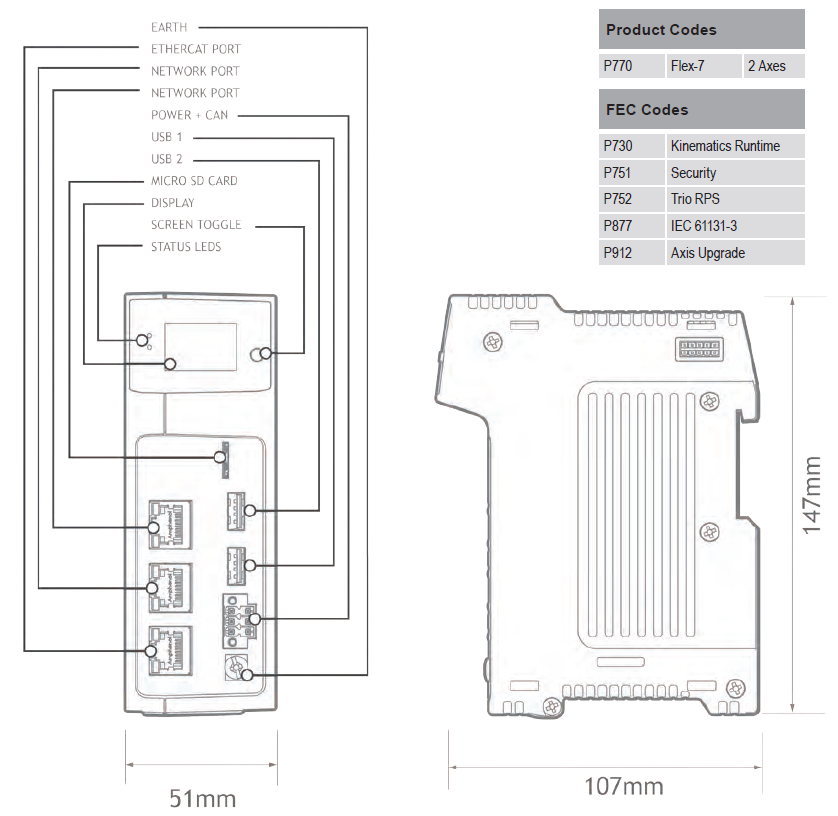

The Flex-7 is Trio’s most powerful, compact Flexible Machine Controller, capable of controlling up to 128 motor axes via EtherCAT, with update rates of up to 125μs. The Flex-7 is based on a newly designed communication interface and a 1.2GHz Quad Core 64-bit ARM Cortex A53 processor, which represents a step forward in performance for Trio’s Flexible Machine Controller range.

Using this quad-core processor, the individual cores are dedicated to motion and communication. Combined with the Gigabit Ethernet hardware, the Flex-7 can handle complex motion and high-speed communication interfaces for high axis count machines. The two Gigabit Ethernet ports enable communication with PLC or factory networks.

The Flex-7 can be used as a stand-alone EtherCAT controller but is also fully compatible with Trio's Flexslice system, which consists of a range of high-performance I/O modules including digital and analog I/O, along with analog servo and stepper motor control, temperature control and encoder interfaces.

The Flex-7 is available to control 2, 4, 8, 16, 32, 64 or 128 motor axes. All versions feature 128 software axes which can be used as virtual axes or via EtherCAT as hardware-assigned servo or stepper axes or encoder input axes. Each axis can be programmed with linear, circular or helical or spherical interpolation, electronic cams and coupled axes.

The built-in Ethernet ports can be used for programming and connection to the common HMI (Trio touch screen). But also for communication with a main machine controller via Profinet, Ethernet-IP, Modbus TCP-IP etc.

Programming and commissioning of the Flex-7 is done using the powerful Motion Perfect development environment. Using multi-tasking application software, complex movements are easily programmed with the Trio MOTION-iX commands and integrated HMI editor. In addition, the standard IEC 61131-3 programming language is available for developing a fully functional PLC program. The result is tested and optimized using a motion controller simulator, HMI simulator, the 3D oscilloscope and 3D machine visualization tool.

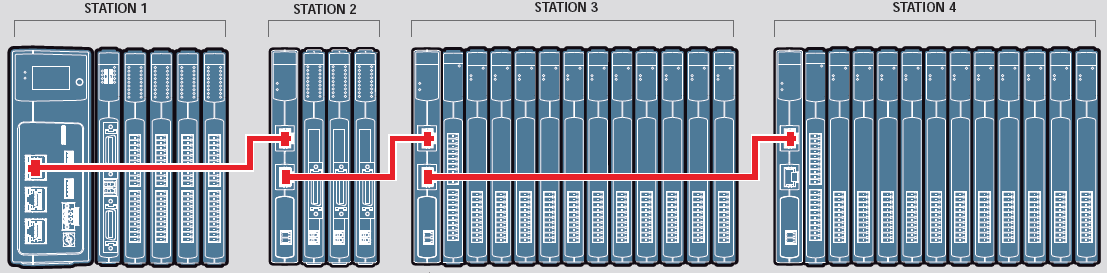

Trio's Flexslice input/output modules offer a robust, fast and flexible solution for both motion control and general automation. EtherCAT cycle times of up to 125μsec are supported and the bus coupler uses EBUS technology to bring all submodules onto the EtherCAT network without any loss of performance.

EtherCAT slave nodes (Flexslice modules) are connected via the Flexslice EBUS and the EtherCAT connector. Total number of slave nodes can be up to 128 including I/O and more complex devices.

Flexslice modules:

ATB Automation supplies motion controllers from Trio Motion Technology and Leadshine. The Trio motion controllers can also be easily extended with various I / O and control panels so that the controller also can operate as stand-alone machine controller .

More information about motion controllers.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.