2024

From challenge to opportunity with Stöber safety technology

A safe machine with minimal downtime, without compromises on performance because safety techniques throw a spanner in the works. “That sounds...

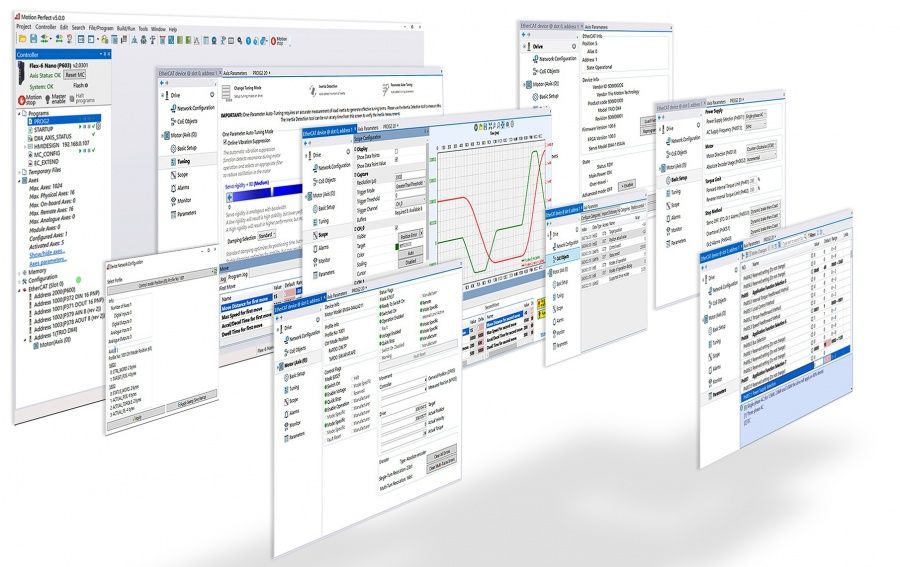

ATB Automation regularly organizes free open Trio Motion Control Application Days. An ideal opportunity to sample the possibilities of Trio Motion Controllers and MotionPerfect software. Check our calendar for the next dates.

We also offer introductory training to support customers properly when they get started with the Trio Motion Controllers. This training can be supplemented with in-depth knowledge sessions if required.

Introductory training is the kickstart for experienced professionals from one company who want to get started with the Trio Motion Controllers. After this intensive day, it is clear to the customer how a project can be started and a clear picture has been created of how the set goals can be realized.

In addition to the introductory training, we offer our customers in-depth knowledge sessions. To follow a knowledge session, the introductory training should always be followed. These sessions are designed to work with the client on certain topics with more depth when they have further questions after following the introductory training.

The sessions are demand driven and therefore have a complete project focus. In addition, the content is hands-on with a practical approach, so that the participants can start working independently with the Trio Motion Controller at the end of the day. Knowledge sessions can take place at the ATB Automation office or at the customer's office. The sessions are composed on the basis of customer needs. We have an inventory meeting with the customer to clarify where the additional knowledge needs lie. During the inventory interview, the customer indicates which modules they want to go into further; albeit superficially, albeit profoundly. A knowledge session lasts at least one part of the day of 3.5 hours. The outcome of the conversation can also show that there is a need for a session of several sessions.

We distinguish various knowledge sessions modules:

After this session, participants can independently program a Trio MOTION-iX application. The commonly used syntax is user-friendly and understandable for everyone. A participant learns how to set up an application with its own routines and functions. In addition, he learns error and error handling. If the project asks for specific issues, such as exchanging the data with parent control, then we will go into this in more detail, so that the possibilities can be fully utilized. In the session we will set up many example programs so that experience is gained and a good reference work is created which fits in with the development of the project.

Subjects: Program Structures, Constants, Logical and Bitwise operators, Comparison operators, Mathematical function, Functions, IO, Terminal, SD-Card storage

After this session, participants can independently program an application. This is usually in addition to a Trio MOTION-iX application. For many PLC programmers IEC61131 is a familiar way of programming, Trio has implemented this and supplemented with own motion commands. Depending on the customer's needs, we explain the possibilities and look for the floor. In the session we will set up many example programs so that experience is gained and a good reference work is created which fits in with the development of the project.

Topics: Structured Text, Function Block, Sequential Function Chart, Ladder

In this session, the participant becomes familiar with the powerful motion commands from the Trio controller. This varies from setting a single axis into motion, until a multi-axle system does exactly what the application demands. During the intake interview, we determine which motion commands fit the project's issue so that they are fully understood. After the session, the participants know all the possibilities of the commands and have built up a reference work to set up their own development.

Topics: Axis -commands -functions -parameters, Move, Move Absolute, Move Absolute Sequential, Move Circle, Move Modify, Movelink, Date, Helical, ADDAX, Spline, Cambox, Kinematics, Cancel, Rapid stop

In this session, the participants will work under supervision to realize an intuitive control panel with the Uniplay touch screen in Motion Perfect. After this session the possibilities of the Uniplay touch screen are clear and a clear picture has emerged of how the HMI can look and how it can be realized.

Topics: Button, Label, Check Box, Radio Box, Progress Bar, Track Bar, List Box, Combo Box, Keypad, Multi Page

In this session, participants get started with setting up a direct connection with an external system to control the motion controller from a parent platform, such as Visual Basic, MatLab or LabVIEW. Together we will establish the link and go through the functionalities. After the session, the participants know how to set up the link and what the possibilities are.

Topics: ActiveX (OCX), TCP / IP, UDP, PC-MCAT API, dual port RAM, IP, TCP / UPD, Microsoft Visual Studio, MatLab, LabVIEW, C, C #, C ++, Delphi, Java, Pascal, G Code

In this session, participants discuss the theory of motion control. What are the mechanical laws and how do we deal with them? How can the effects of acceleration and deceleration be optimized and what are the parameters that can be run? Depending on the customer's needs, we discuss the linear or rotating world or a combination of both. After this session the participants are able to optimize mechanical movements and prevent resonances and to solve them.

Topics: Newton, PID, proportional-integral control systems, Laplace, FFT (Fast Fourier Transform), force, torque, speed, (angle) adjustment, distance, resonances, oscilloscope, I/O, gain

In this session, participants will simulate which errors can occur in the system. Questions that are being dealt with include; When an error occurs, how should it be handled? Should the system come to a standstill? How should the error be made known so that the error can be resolved? How can the system be put into operation again? After this session, a clear overview of errors (malfunctions) that can occur and how to respond to them.

Topics: Run, Stop, Halt, Cancel, Rapidstop, Machine status, Clearing Errors

In this session the participants start to realize a multi-axial movement. Depending on the project requirements, we will handle an appropriate selection of commands to carry out the movement. After the session, the participants are familiar with the possibilities and are able to apply them independently.

Topics: MC4N feature, Frame transformation, Kinetics, Scara, Spider, Cartesian / Polar

In this session we explain how the Trio Motion Controller can be provided with data from an external source. The different interface possibilities become clear, so that a choice can be made that is appropriate for the project. Once the choice is made, we start hands-on and the chosen connection is set up. After the session, participants are able to build up the connection independently.

Topics: PC-MCAT main features, Getting started, Dual port RAM, I/O Expansions

Contact:

Peter Hamersma

system integration & project manager

+31 297 38 05 63

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.