2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

Date: 15 November 2016

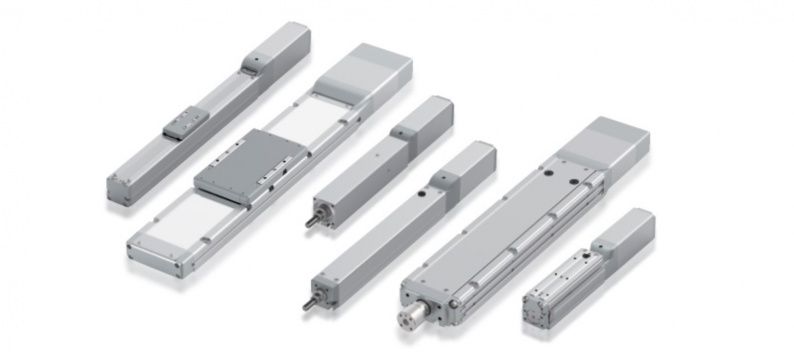

IAI brings with the new generation RCP6 linear actuators a flexible and robust solution to market with high repeatability for every positioning application within a range of one meter.

Each type is equipped with:

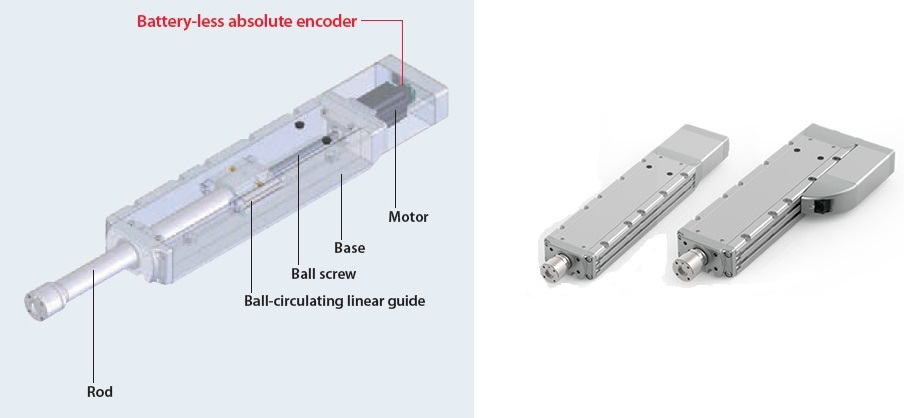

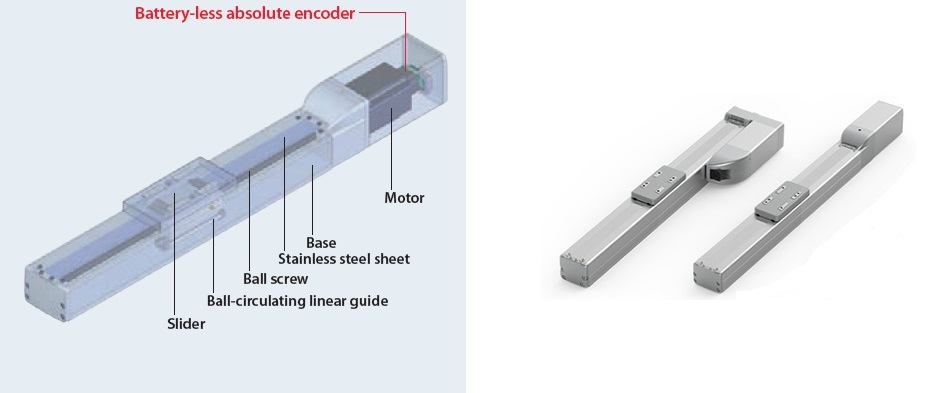

Version with rod and integrated ball screw. for high radial loads and moment loads.

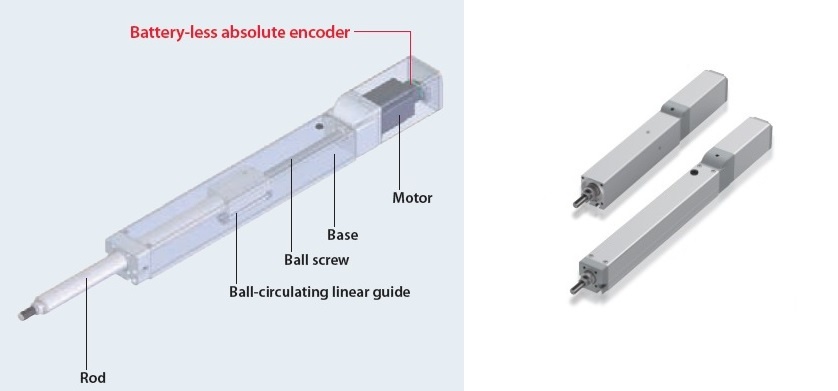

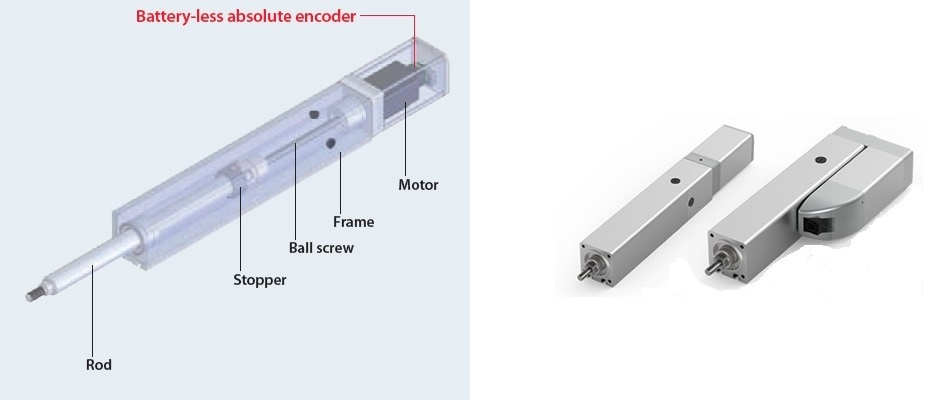

Version with rod without linear guide. Least expensive model, ideal for replacement of pneumatic actuators.

Uitvoering met drijfstang met brede behuizing en kogelomloopgeleiding. Hierdoor kunnen zeer hoge krachten en momenten op de drijfstang worden opgevangen

Version with slider and integrated ball screw, for mitigation of moments in all directions. Therefor these actuators are ideal for composing a XY or XYZ system.

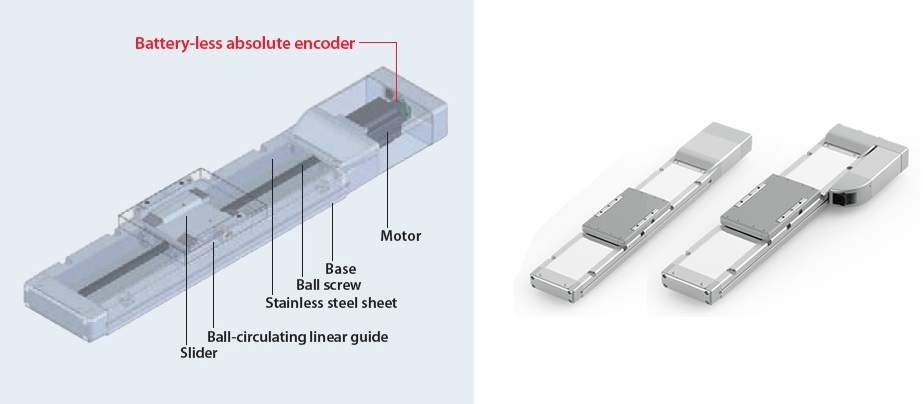

Version with wide slider and integrated ballscrew for mitigation of high moments. Hence the RCP6-WSA is a perfect actuator as basis for a cartesian system.

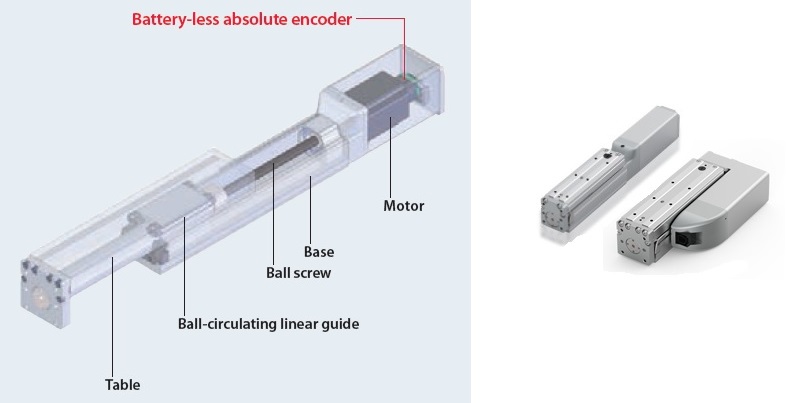

The RCP6-TA table type actuator suitable for a steady load movement, especially vertical payloads. The load can ben mounted with the thread holes on the surface of the table and end plate.

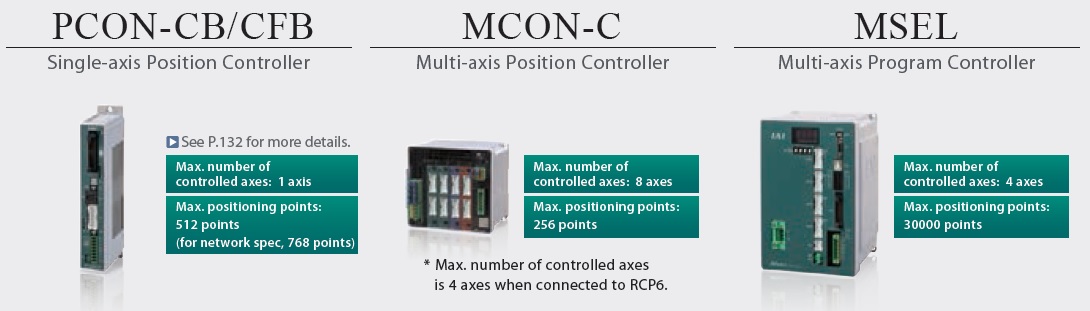

All types RoboCylinders linear actuators from the RCP6 series can be executed with an integrated controller next to the 24V stepper motor and absolute encoder.

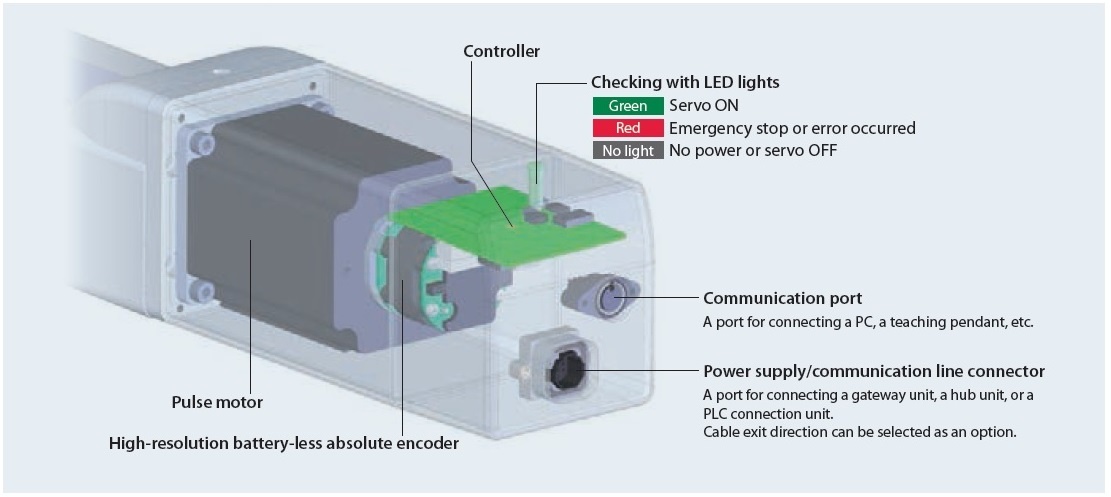

The actuator equipped with:

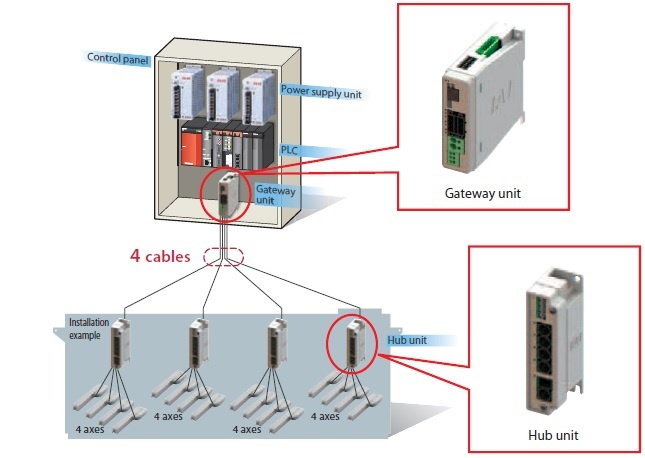

By using the gateway unit, a maximum of 16 axes or RCP6S actuators can operate via a field network:

To each gateway 4 pieces RCP6S or 4 hubs can be connected direcly. Subsequently 4 stuks RCP6S actuators can be connected on each hub (type RCM-P6HUB).

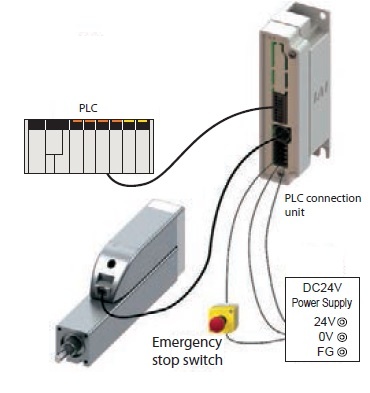

Via the RCP-P6PLC connection module the RCP6S can easily be controlled from a plc via serial communication .

Download the complete RCP6 catalog here

|

Please contact: Martin van der Steenhoven |

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.