2024

From challenge to opportunity with Stöber safety technology

A safe machine with minimal downtime, without compromises on performance because safety techniques throw a spanner in the works. “That sounds...

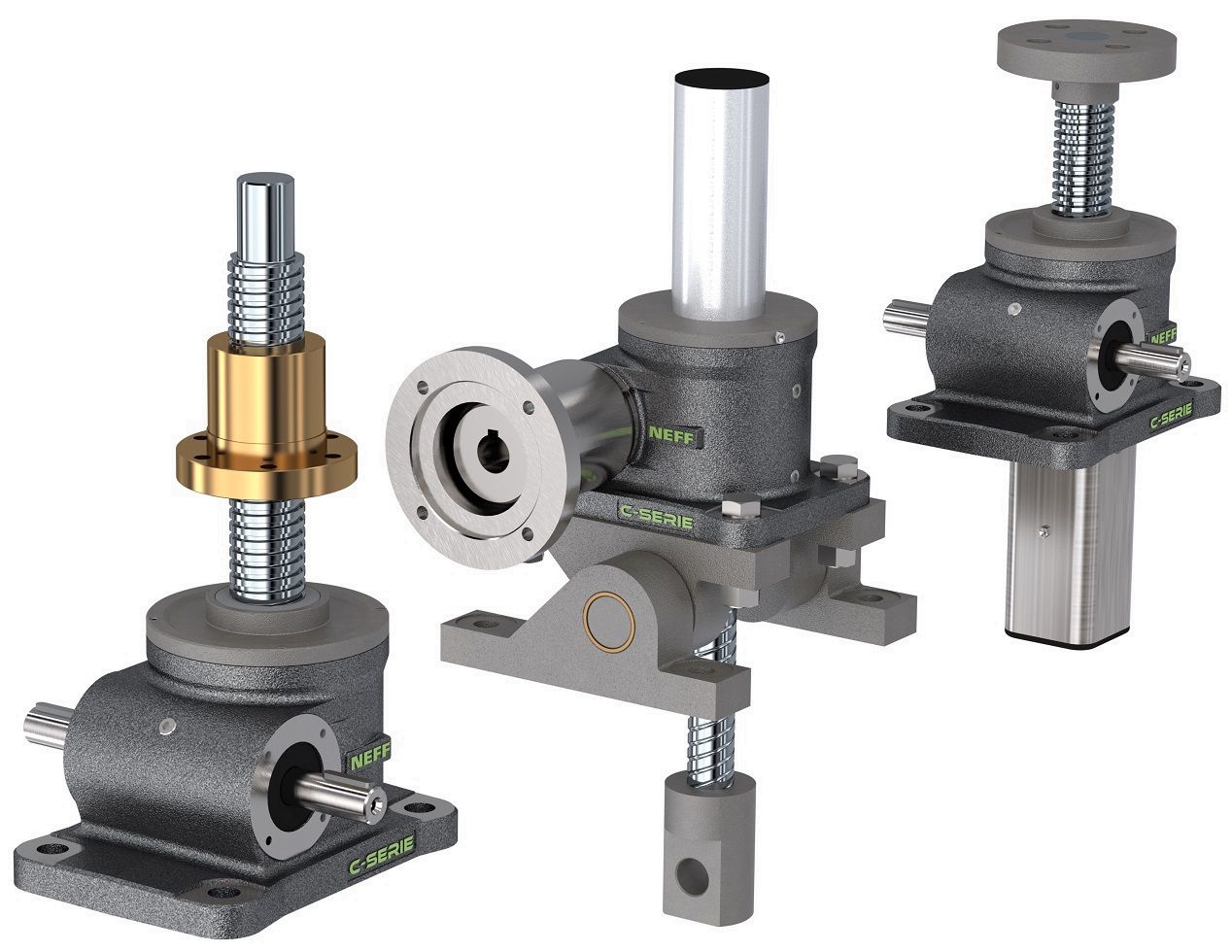

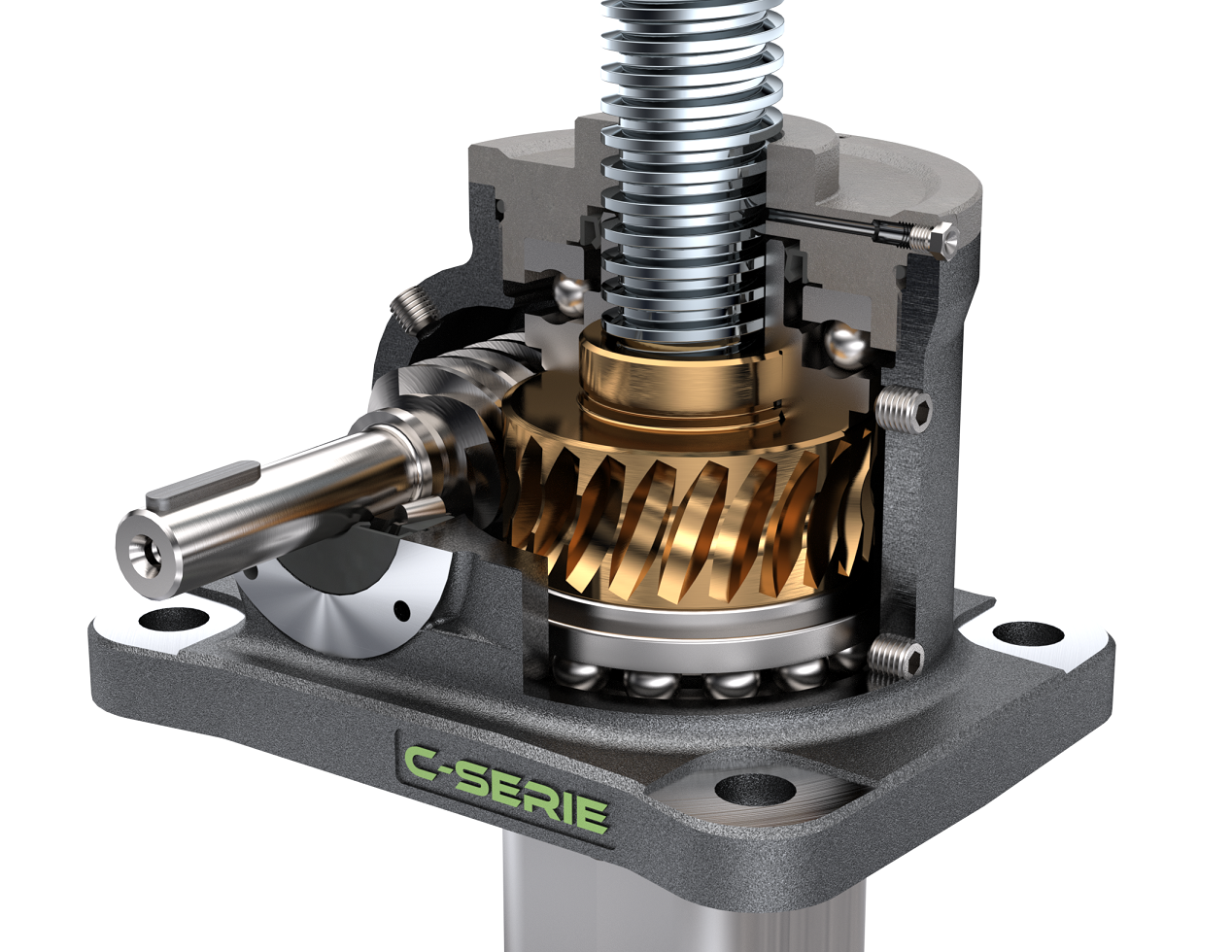

Lifting systems for various applications with standard screw jacks, worm gear screw jacks, actuators and precision screws for lifting capacities to 500 kN.

ATB Automation supplies components in mechanics and Motion control technology. Spindle lifting elements, screw jacks, are an important product group within the Mechanics group. With lifting forces of up to 500kN, there are solutions for various industries. The spindle lifting elements can be driven with a wide range of motors and drives from the Motion Control range of ATB Automation.

The NEFF spindle lifting elements are high-quality products and have a long history. Wilhelm NEFF opened a mechanical workshop in Waldenbuch in 1905. Since the 1980s, the focus has been on spindles and spindle lifting elements.

The most famous spindle lifting element in the industry. A robust product with a proven service life. The main features are :

With over 65 years of experience in drive technology, ATB Automation provides advice for any desired industrial drive problem with a delivery program from extremely compact servo drives to linear spindle lifting systems in the most diverse industries.

Contact us directly for advice on the most suitable servo motor for your application:

Delivery in the Netherlands, Belgium and Luxembourg.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.