2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

Date: 29 April 2024

It is clear that the conversion of hydraulics to electric or electro-mechanical actuators is a relevant topic in mechanical engineering: my colleague Henry le Noble previously wrote an article on this subject and I answered the 5 most frequently asked questions about electric actuators. But of course there are many developments in this dynamic world. High time for an update.

To get straight to the point: I notice that many machine builders want to replace their hydraulic drives with electric or electro-mechanical actuators. They often come to my table, because they know that ATB has a significant 'track record' in this area and can show successful examples from practice.

And during those conversations we quickly get to the core: people want to innovate, but they also don't want to make the cost price of the machine too high. Understandable!

An important and frequently heard argument from machine builders to fall back on hydraulics is therefore cost considerations. The idea is that people want to continue to compete against the competition.

And that is precisely where the greatest strength lies: because electric drive makes machines much more reliable and therefore makes the machine more valuable. And this puts you as a machine builder ahead of the competition.

The increase in value is truly a unique selling point for the buyers of your machines. We also often hear this from our customers:

In summary: it is an investment that pays for itself.

A topic that has become increasingly relevant in recent years is sustainability. More than ever before, customers require your machines to operate economically, cleanly and efficiently on their work floor.

This also provides environmental benefits on these points: electric and electro-mechanical actuators are energy efficient and environmental damage due to oil leakage is excluded.

Examples of successful replacements? We have enough of those! Good cases include the replacement of the hydraulic drive on the gas valves of a gas turbine or an application in which blood bags are pressed.

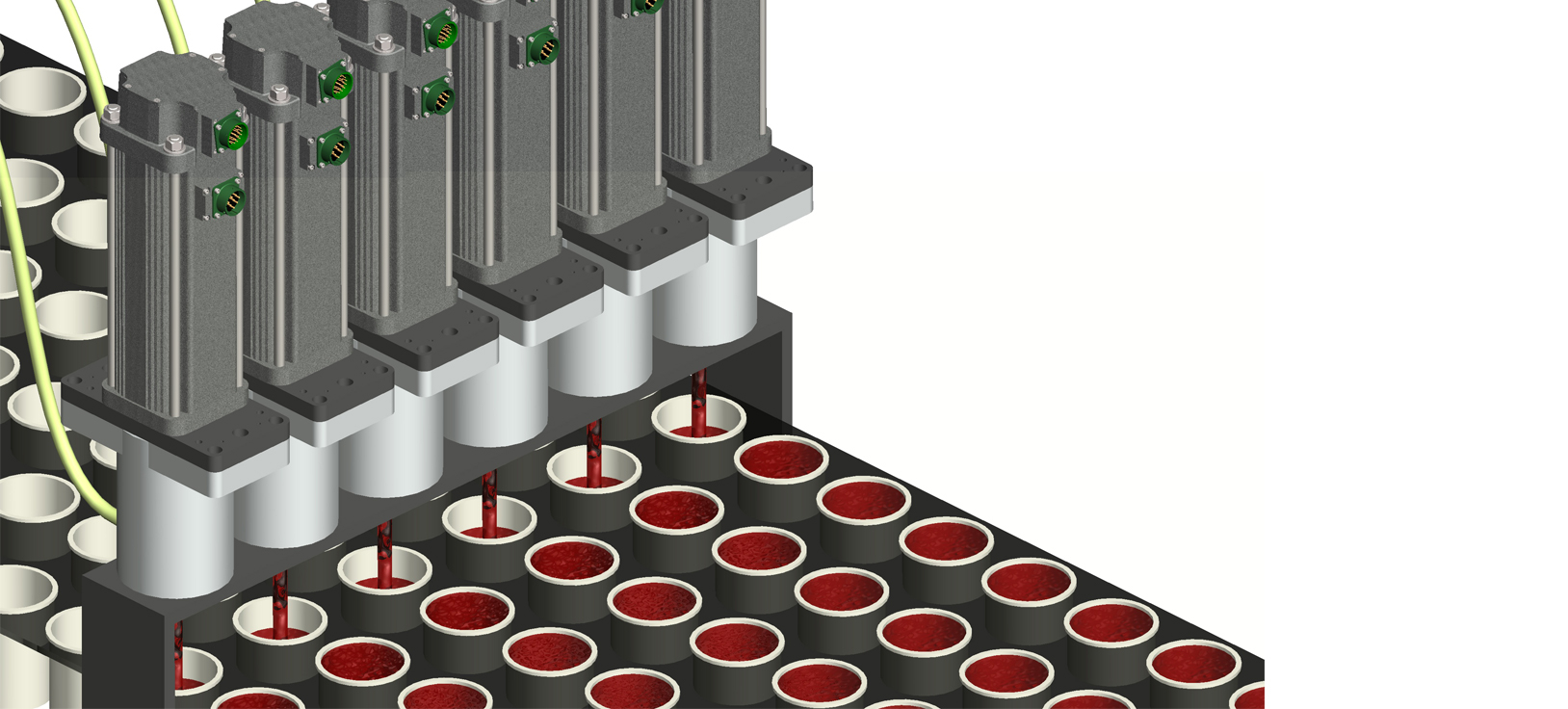

It is good to mention that our actuators are also an excellent replacement for pneumatics, for example in the food processing industry. For example, our Exlars are used in a dosing application for pesto and syrup waffles.

I imagine that all these arguments sound good, but also raise more questions for you. Then you have come to the right place: please feel free to contact me and I will be happy to tell you more about all the possibilities!

+31 297 38 05 54

martin@atbautomation.eu

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.