2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

Date: 14 September 2017

With great expectations I was looking forward to it. I went to Rosta in Switzerland for a basic product seminar. On Monday, June 26th, I left from Zaventem Airport towards Switzerland. After a flight of over an hour, the plane landed at Zurich Airport.

Once I arrived at the airport I went searching for Bruno Weltzheimer (a colleague of Rosta). Thanks tot he directives sent by Rosta in an e-mail, it was very easy to find Mr. Weltzheimer (Sales manager of France, Morocco and Tunisia) at the agreed place at Zurich Airport. After having a drink we went to the hotel (Hotel Aarau West) together to drop off our luggage and freshen up for dinner.

At 18.45 I walked towards the hotel reception and I got acquainted with other representatives of the Rosta Group. The representatives came from all corners of the world, namely: Sweden, France, Norway, Slovenia, Finland, Germany, Italy, America and Australia. At 19 o'clock we went all the way to the 'Golf Restaurant' in Oberentfelden (right at the opposite of the hotel) for dinner. After a delicious dinner and a nice conversation with the other representatives, most of us, including myself, went to the hotel to get a goodnight sleep for the seminar the next day.

Off to the factory of Rosta in Hunzenschwil

The fact that Swiss people have precision appears soon. At 8.15 pm, according tot he appointment, I traveled from the hotel tot he ROsta factory with the representatives from the other countries. At the factory we met Marc Mollenkopf, the CEO of Rosta AG. He welcomed us and introduce dus tot he people who were going to accompany us during the seminar.

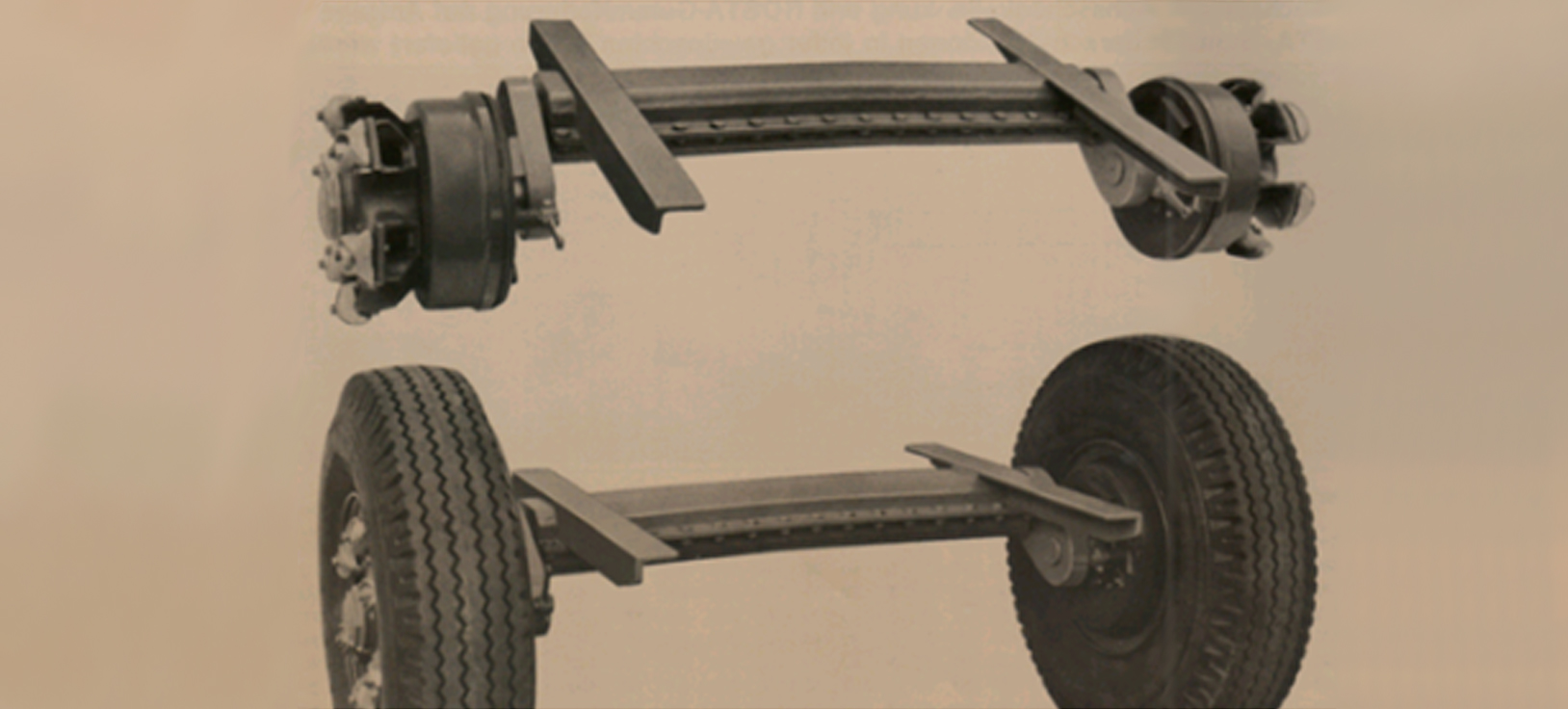

The factory was founded in the mid-forties 1941 by Mr. Ernst Rohr in the village of Staufen (ROSTA). It all began when he was chosen to develop a simple and economic solution to support axles of truck trailers. The three main functions (to support, to dampen and to suspend) lead to the Rosta rubber suspension units.

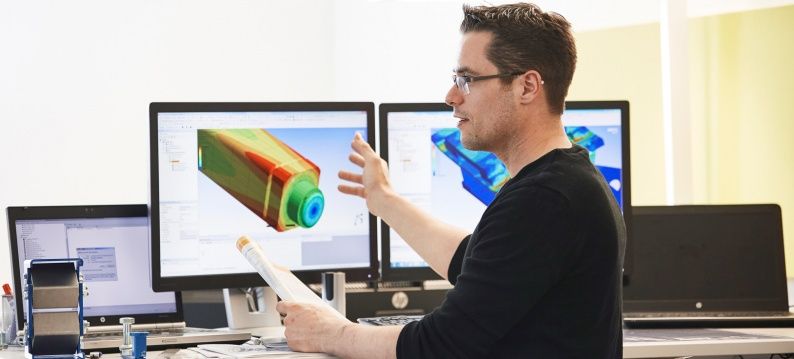

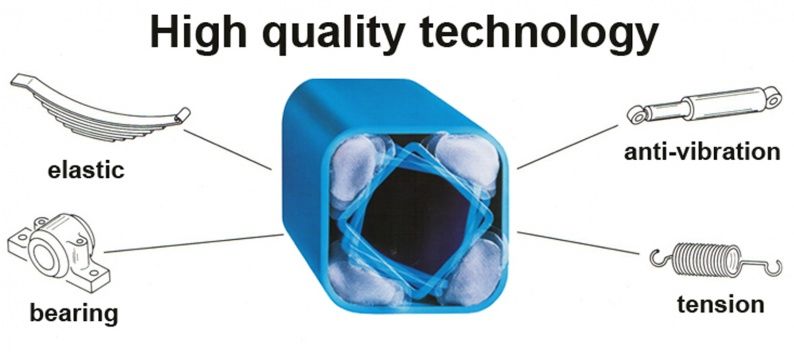

After some history about Rosta Mr. Philippe Matter (Marketing and Sales manager) started with our first lesson: The technology of rubber suspension. He explained the characteristics and the expected lifetime of the rubber suspension units. He also showed us some applications in which rubber suspension units can be used and in which situations. It soon became clear that the quality of the rubbers is very important.

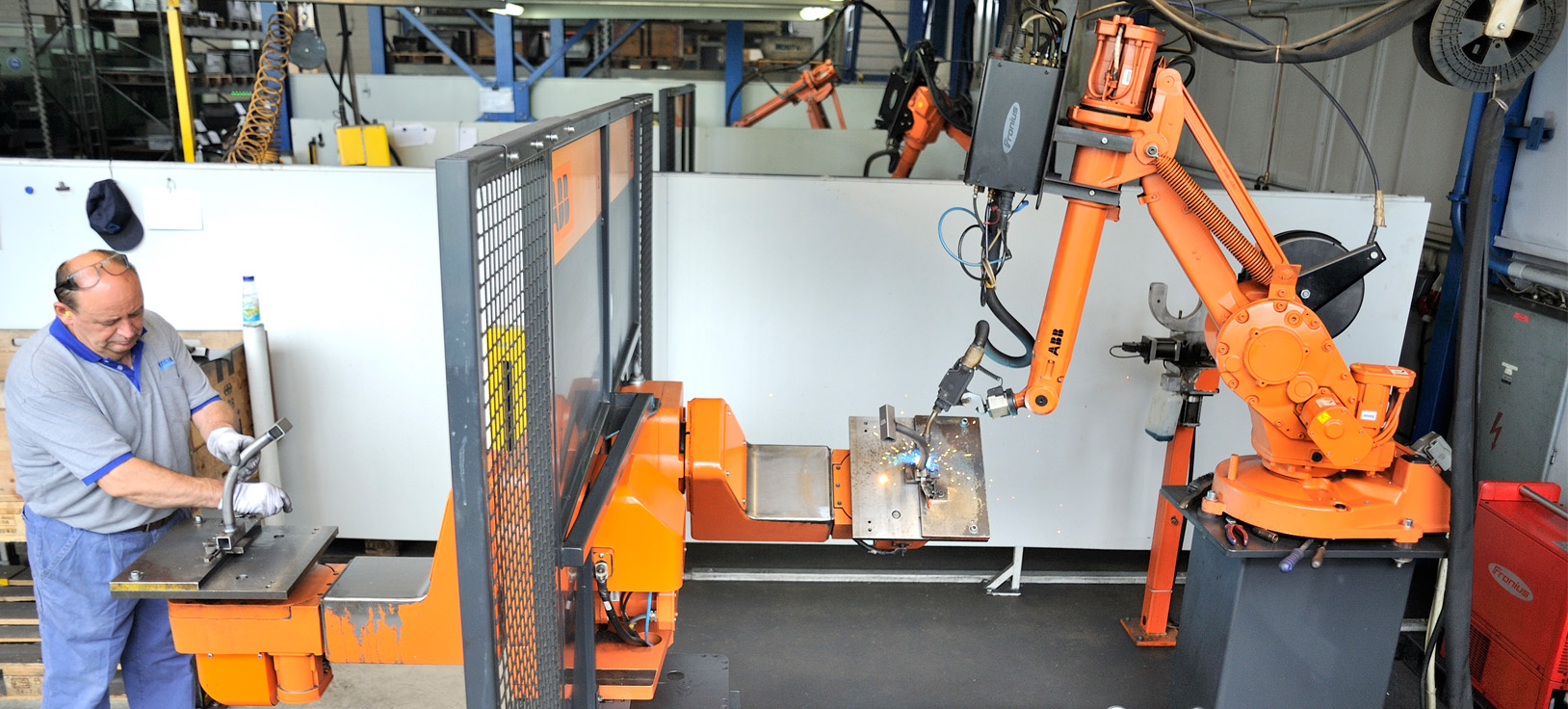

After an educative mornig it was time for lunch. After lunch we had a tour in the Rosta factory. There we have been able to see the production from base till end product. They have a large stock of rubbers and steel pipes. Occasionally they take an element of production and measure them to see if they meet the requirements. Also in the laboratory these elements are tested for all kinds of forces and in different conditions. What one can say about Rosta is that they know what they are selling.

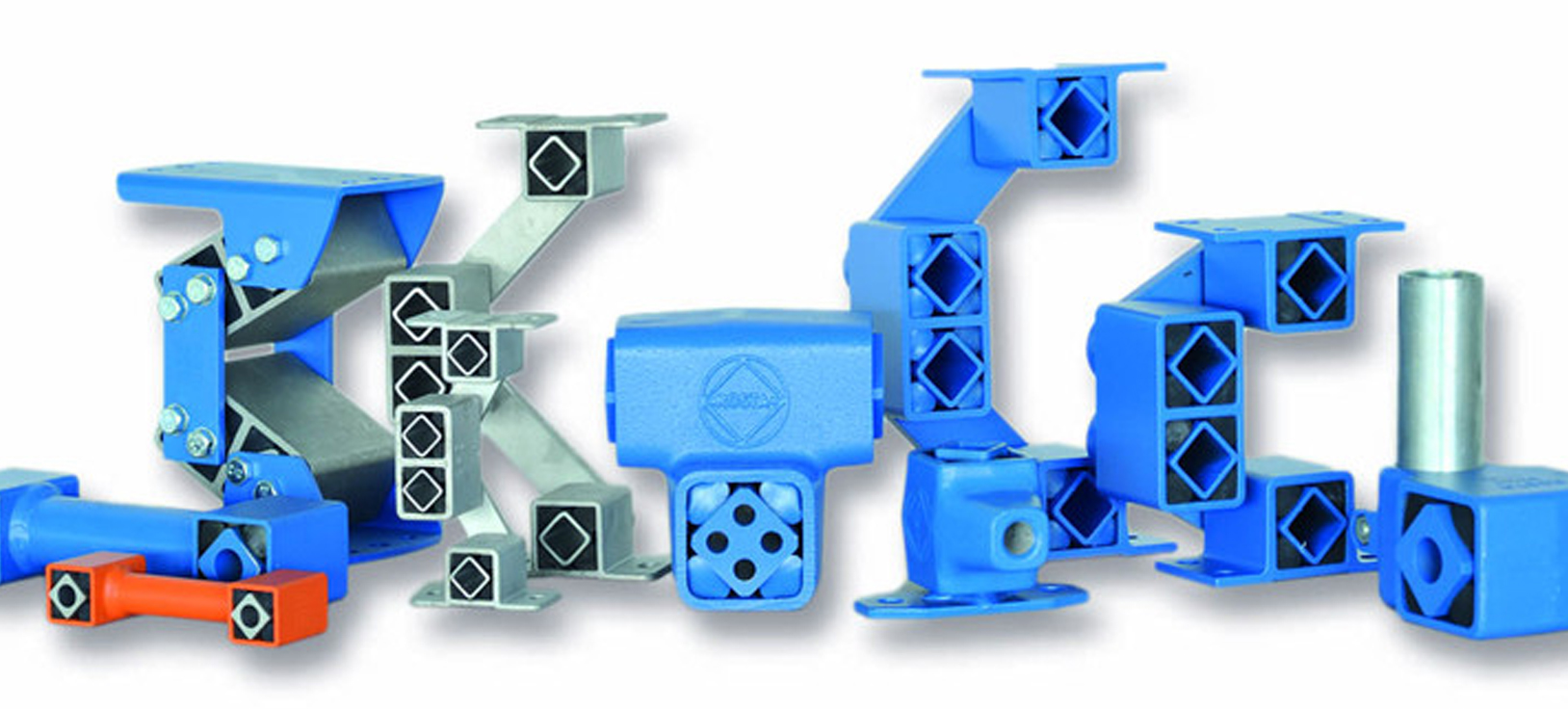

After our tour the lesson was resumed, but this time it was about the anti-vibration mounts of Rosta. We also took a look at the characteristics and how to choose the right anti-vibration mount.

Original Rosta versus copies

Dag 2 started with a test of what we saw the previous day. This was very educational. After that we started with the presentation of Rosta tensioner devices and then proceeded with motorbases. With more thane 75 years of experience Rosta features good and reliable quality. Rosta does what it has to do! Both the tensioner devices (SE) and the motorbases (MB) were discussed. There are a lot of brands that copy Rosta and that is normal, because Rosta is a well-known and reliable brand. It is well-known that ‘popular’ brands are copied by other companies to also have a piece of the cake. But as we all know most copies are not of the same quality as the original ones. We have experienced this in the showroom of Rosta where several copies were standing next to each other with the same dimensions and were installed at the same time all bearing the same load. Also the original components of Rosta were among the lucky ones. One by one we could test the differences between all the tensioner devices. Soon everybody came tot he conclusion that Rosta was the winner of the test. Most of the tensioner devices felt stiff and were more soaked than the Rosta tension element. Also the suspension unit was much more robust than the element of Rosta.

This afternoon we did not only got theory and test the rubber suspension units, but we also actively participated in compilating tensioner devices and motorbases First we had to decide which rubber suspension unit we could use. Then how to install and tighten the rubber suspension unit.

Closure

The last day of the 3 day seminar was already there and at Rosta they put us throught a second test of everything we sa wand learnt on day 2. Afterwards we went through the test together and we were able to give our feedback. Given the short time that remained, we got to learn something about oscillating mountings (AB). Before I was dropped off at Zurich Airport they invited me and the other representatives for a nice dinner as a closure of the seminar. After dinner I said goodbye tot he group and took the plane to Zaventem. I had an educational and fun seminar at Rosta!

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.