2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

Date: 2 June 2015

Every company has its specialties and qualities. I got to experience this too at the high-tech company IGS GeboJagema, which has a large number of highly educated and skilled precision engineers. They excel in the design and manufacture of high precision injection molds. Our partnership with IGS GeboJagema is a great example of a partnership between two companies that complement each other, each with their own specialty: IGS in precision engineering and Mijnsbergen in motion control and drive components and systems.

For me it is a challenge in every project to gain a clear insight in what exactly are the customer's needs. With the IGS project the key priorities were flexibility in settings and control over the process. When those needs are clearly defined, it's my biggest challenge how to realize a constructive contribution to the manageability and reliability of the process. The added value for IGS of the cooperation with Mijnsbergen is readily apparent, as we not only supply the components, but also provide the complete solution. We approach cooperation as a partnership where we present a total package of "unburdening".

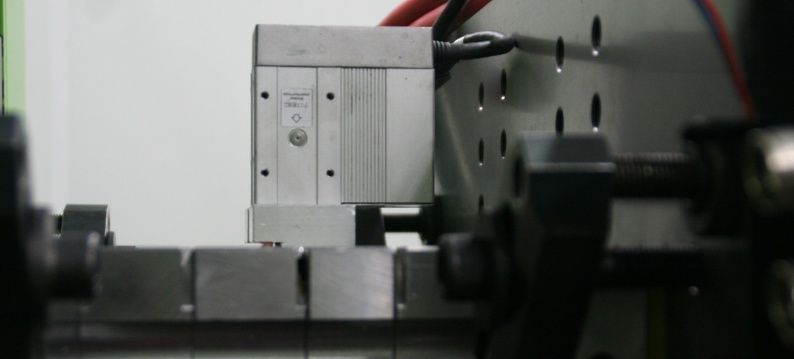

We have previously supplied IAI electric actuators to IGS for a prototype with a motion between fixed positions and with fixed speed. Now IGS required a complete motion control system with control cabinet and touch screen control panel, which enables multiple options. We have implemented with the development of the display and designing and assembling the control cabinet. IGS can flexibly adjust everything via the control panel IGS, so that they can configure the process all the way to suit their needs.

Companies may be reluctant to outsource a design and development of a complete system by a third party. Often because they expect high costs. Our experience teaches that the customer ultimately saves time and money, by entering into cooperation. Where customers often have to build up the experience with motion control and / or control systems, we can draw on our many years of accumulated experience. We have good designing software at our disposal, we can design and develop the control cabinet and make a risk assessment. Ultimately this saves many revisions and adjustments during the project due to inexperience. This may not be foreseen prior or at the start of the project, but will become evident afterwards when all the extra hours and resources for solving unexpected problems are included.

I/O communication is very important for the connection between the motion control system and the injection molding machine. In the control cabinet we have made for IGS, a safety circuit is included for emergency stop buttons and door switches. Additionally the Trio motion controller controls up to four drives, which each control one actuator. We have built the connection between the control cabinet and the machine to customer specifications according to the Euromap 67 standard (the standard for injection molding machines).

Our experience in the past 15 years is that customers can safely put the responsibility for the motion part of a system with us, so they can concentrate to what they excell in. Resulting in a collaboration between two specialists, with great money and time savings.

» Learn more about motion control project design? Please contact Peter Hamersma.

+31 297 38 05 63

peter@atbautomation.eu

Peter Hamersma has been working at ATB Automation since 2001, starting as a software engineer. Peter is responsible for supervising the motion control projects of ATB Automation and, as a specialist in servo drives and motion controllers, he is also responsible for system integration. With more than 25 years of experience in the field of servo systems and the motion controllers of Trio Motion Technology, Peter is one of the most experienced specialists in the Benelux.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.