2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

Date: 12 August 2025

"Approximately one third of motors are equipped with friction belt drives. The performance and efficiency of many belt drives can be improved through the addition of dynamic tensioning technology, the resulting reductions in electricity consumption and associated CO2 emissions can be significant."

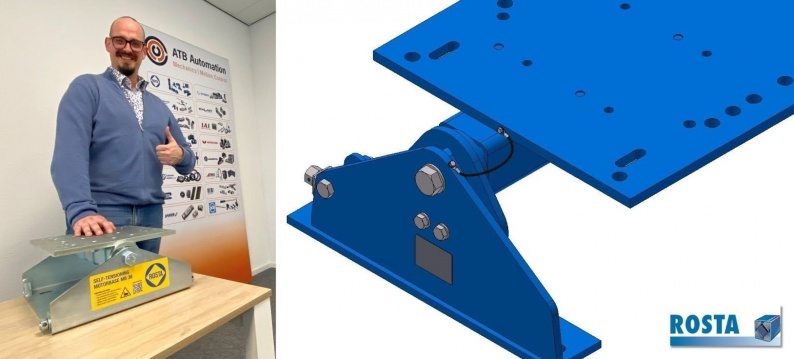

I have been employed by ATB Automation as a sales engineer for 2 years. One of the products that I like to recommend to our customers are the multifunctional Rosta rubber spring elements because they allow drive users to achieve significant savings in terms of durability, cost price and operational reliability.

A good example is the use of a motorbase. A motorbase is a mechanical pre-tensioning unit on which a motor is mounted, which achieves optimum belt tension. It is a self-tensioning system that requires no additional checks or maintenance after installation. The most important result is that the efficiency of the drive system is significantly increased and energy losses are minimal.

At a customer, active in the extraction of raw materials, we carried out a test by calculating an installation in which 4 transport systems are each equipped with an 11 kW asynchronous motor. It has been calculated that more than € 4,000 will be saved in energy on an annual basis by using 4 Rosta MB38 motorbases. If we compare that with the investment of these 4 motorbases, it quickly becomes clear that the investment will be recouped within a year.

In addition to this saving in energy, our customer also saves on minimal wear of the belt and especially on minimal downtime for maintenance or repairs.

Saving costs and optimizing operational reliability is always an important trigger and factor for investments for users. But in recent years there has been a growing realization that saving energy is not only a saving in costs, but above all a significant reduction in CO2 emissions and therefore an important contribution to the preservation of our world. If we further calculate the application of the customer mentioned, it appears that in addition to the saving of € 4,000, CO2 emissions are also reduced by no less than 1.8 tons annually. It is therefore great that with the Rosta rubber spring elements we also contribute positively to a sustainable world for our future.

Would you like to calculate for yourself what your savings in energy costs and CO2 emissions could be? Rosta has published a calculation program, which you can find by clicking here. Naturally, I or one of my colleagues will also be happy to visit you for advice and to calculate the costs.

+32 2 588 80 08

michael@atbautomation.eu

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.