2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

Date: 27 October 2016

Since 2011 I have been working at ATB Automation. From the start I was positively surprised and enthousiastic about the many products and solution within the delivery program. Choosing one in particular, I'd like to highlight the roller screw actuator of Exlar with it's many advantages.

25 years ago Exlar developped the patented electric servo actuator with inverterd roller screw. A revolutionary development, with the roller screw spindel integrated in the rotor of the servomotor. Compared to the existing solutions, like pneumatic and hydraulic actuators or actuators with ball screw, the roller screw solution of Exlar has brought many advantages upon the market:

The Exlar roller screw actuator is an electric servo drive with position feedback and closed position loop. Compared to a hydraulic or a pneumatic drive, the Exlar actuator can be controlled better and more precise for positioning. As a result a higher and better output of a machine. Furthermore, the actuator can position at any given position, resulting in fast and flexible switching of position, i.e. product.

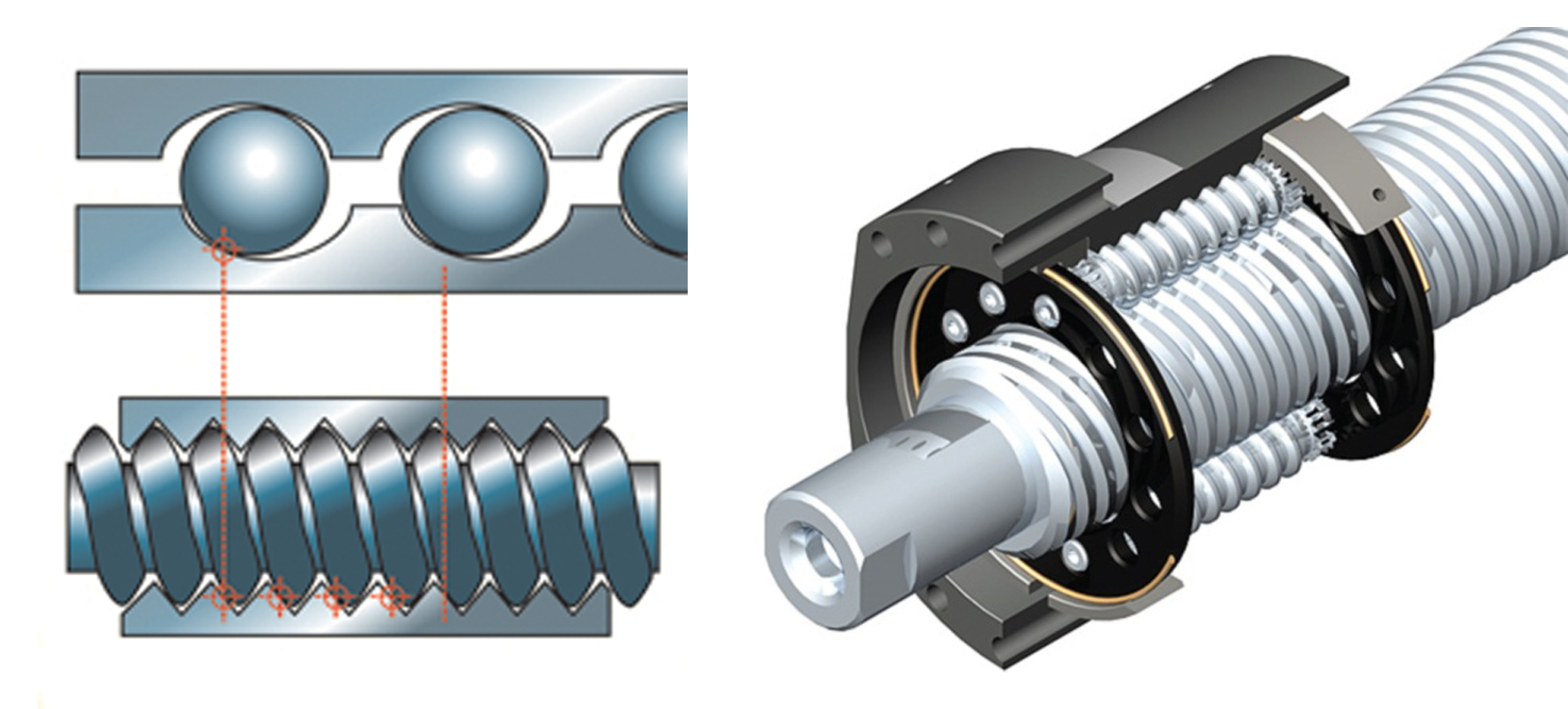

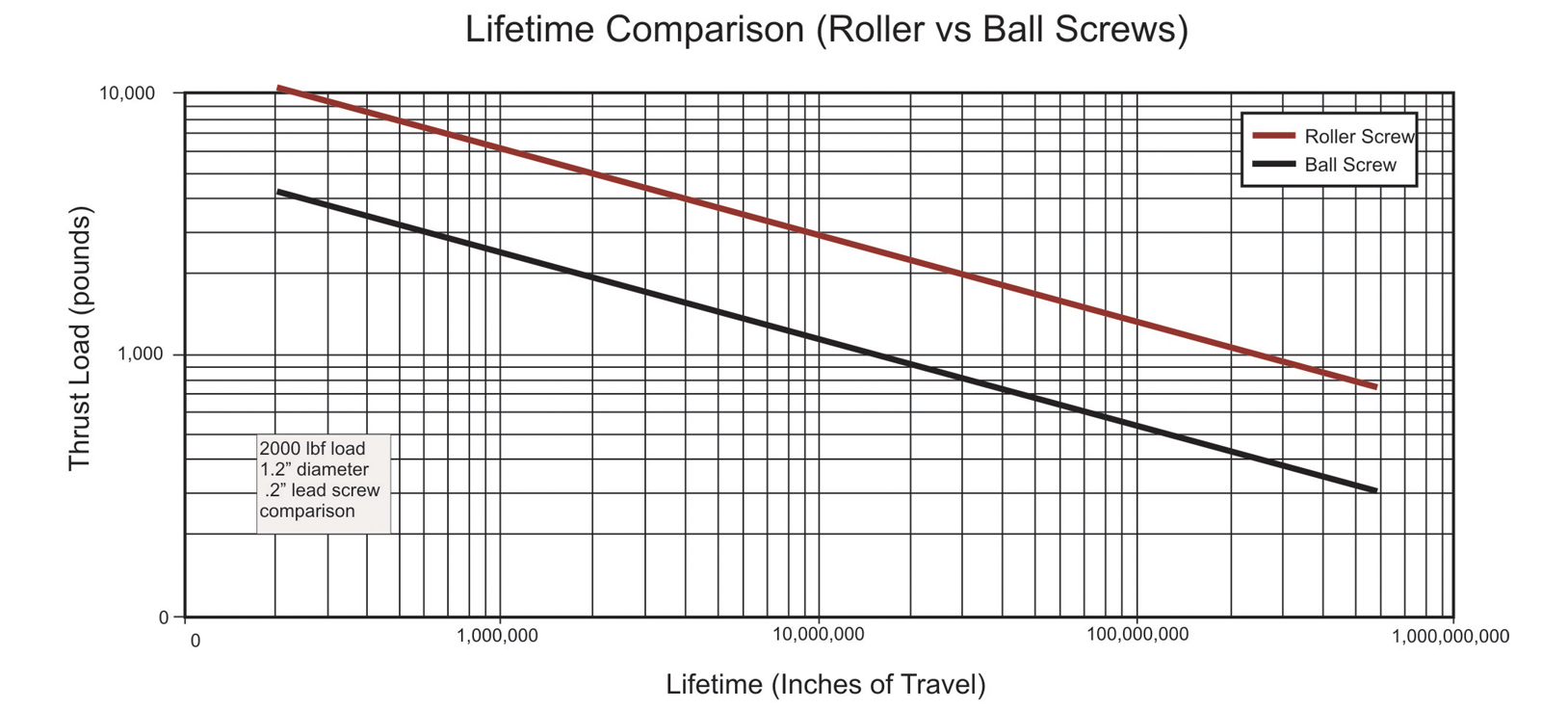

The contact surface of the roller screw is larger than with a ball screw. The dynamic load rating is thus two to three times larger. The actuators with roller screw therefore have a lifespan up to 10 to 15 times longer than actuators with ball screw.

10 to 15 time longer lifespan thanks to larger contact surface of the roller screw.

10 to 15 time longer lifespan thanks to larger contact surface of the roller screw.

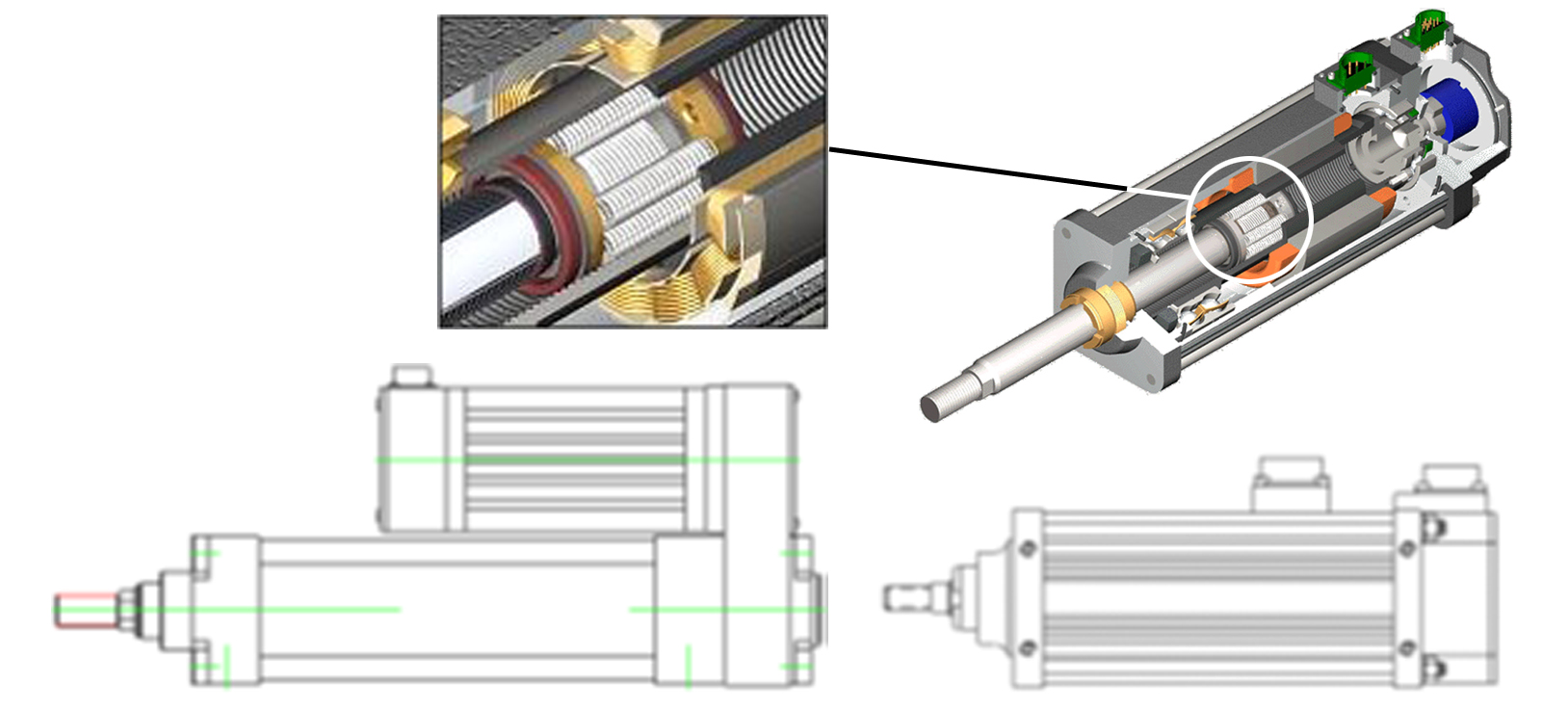

Exlar developped this special patented constructions, where the roller screw is integrated into the rotor of the servomotor. The roller screw converts the rotative motion directly into a powerfull linear motion. A much more compact construction than actuators with a parallel or in-line mounted motor.

Much more compact construction thanks to the integrated servomotor with roller screw in the actuator.

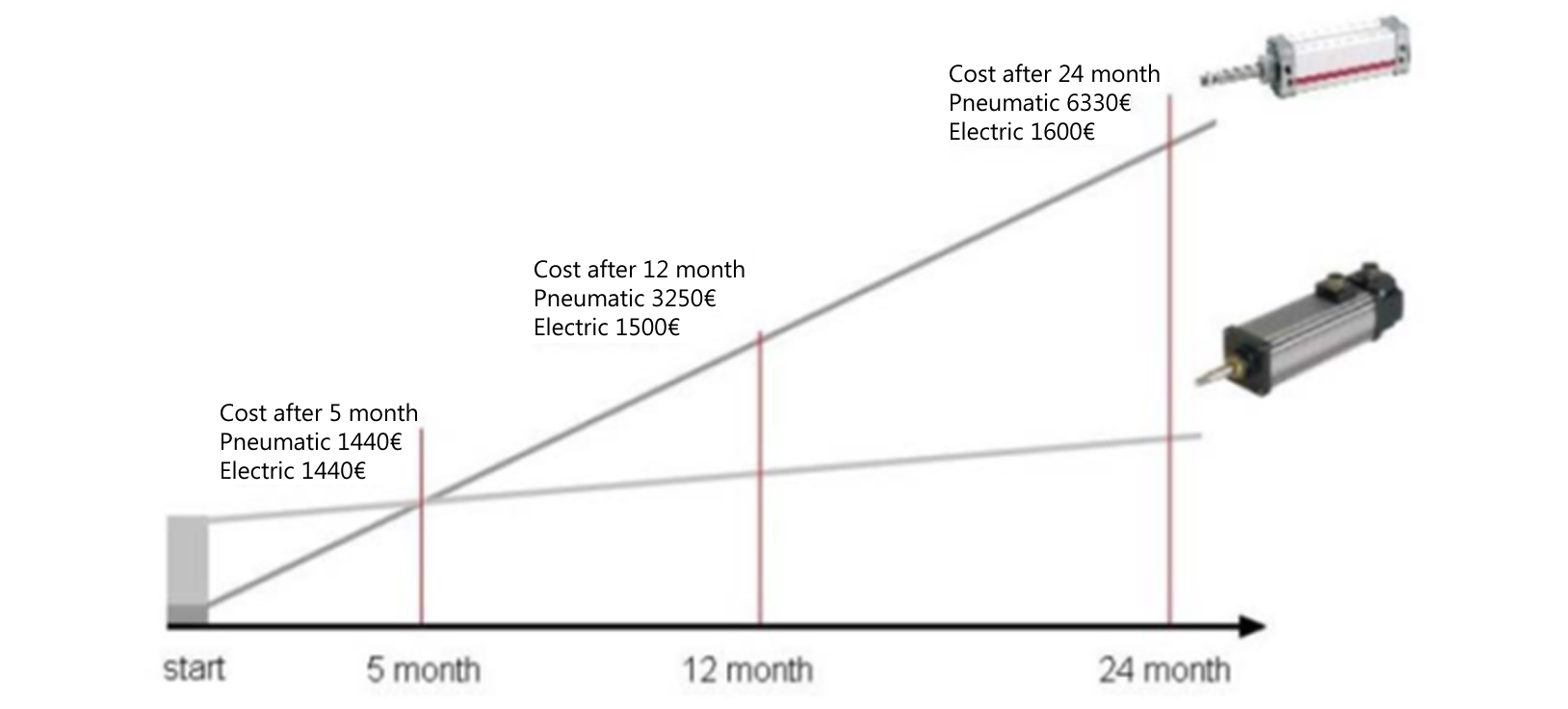

Though the roller screw actuator has a higher initial cost price than pneumatic or hydraulic drives, they offer considerable cost savings in the long term.

An electric drive only uses power under load, whereas a pneumatic or hydraulic drive uses constant energy.

Comparable realistic situations have shown that the energy consumption can come down with a factor 15 lager.

The environment of course benefits from a lower energy usage. But also disadvantages like oil leakage or noise nuisance through air in a production environment belongs to the past, when using Exlar roller screw servo actuators.

The Exlar roller screw actuator is available with encoder or resolver for any type and brand servo drive. Exlar tests the actuator for the most common drives worldwide. The actuators are supplied with connectors according to supplier specification of the drive, suitable for standard cabling.

And for one-axis positioning applications Exlar has launched the Tritex actuators, a complete roller screw actuator with integrated drive, where can be positioned point to point throuhg digital I/O or a bussystem.

As a result of these advantages, the Exlar roller screw actuators have been deployed in many markets and applicaitons such as:

Interested in seeing and experiencing an Exlar roller screw actuator with your own eyes and hands?

Call or mail me for an appointment.

+31 297 38 05 54

martin@atbautomation.eu

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.