2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

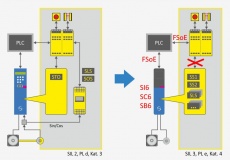

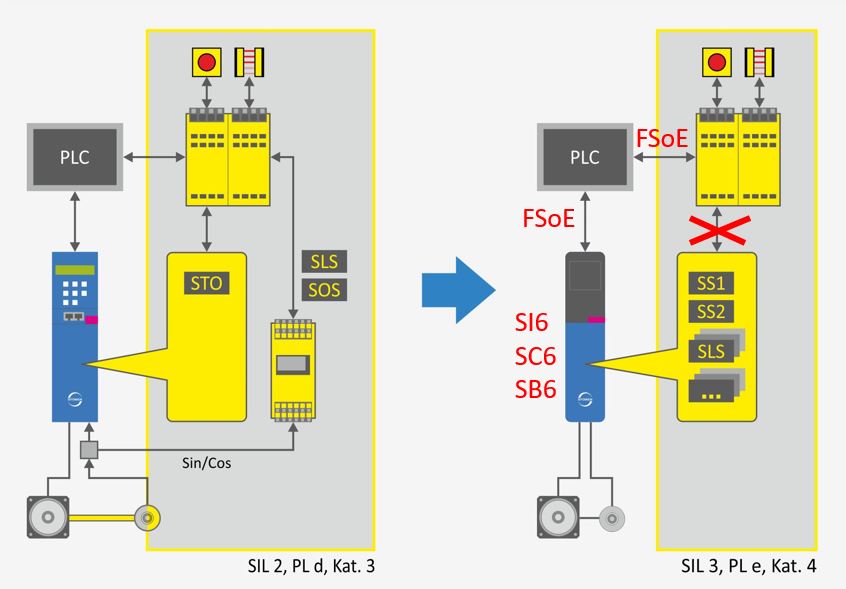

Flexible and affordable expansion of a large number of safety functions for the Stöber SI6/SC6 servo controller in accordance with EN 61800-5-2. With the PASmotion software from Pilz integrated into the DriveControl Suite setup software from Stöber, the specialist knowledge and experience of two worlds come together.

The result is simple and flexible setup of safety functions for STOP, MOTION, MONITORING, BRAKE, RESTART and STATUS in the high-performance stand-alone SI6/SC6 controller from Stöber.

Key benefits:

This saves space, time and costs

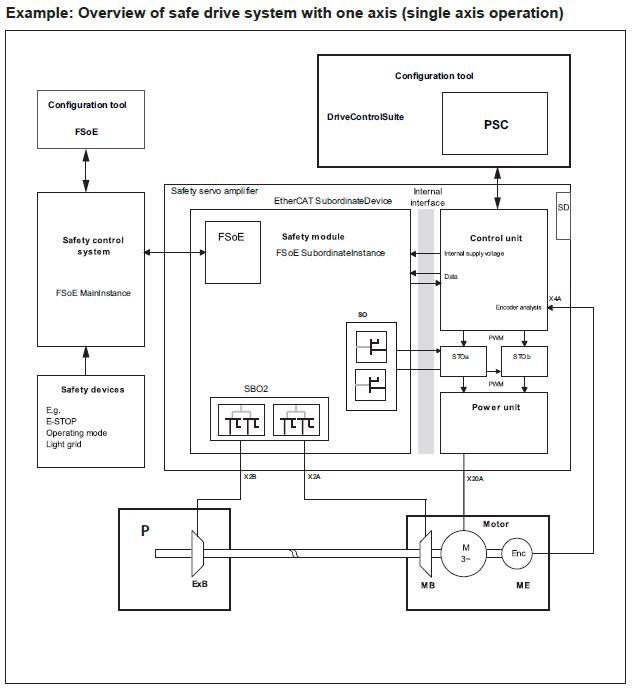

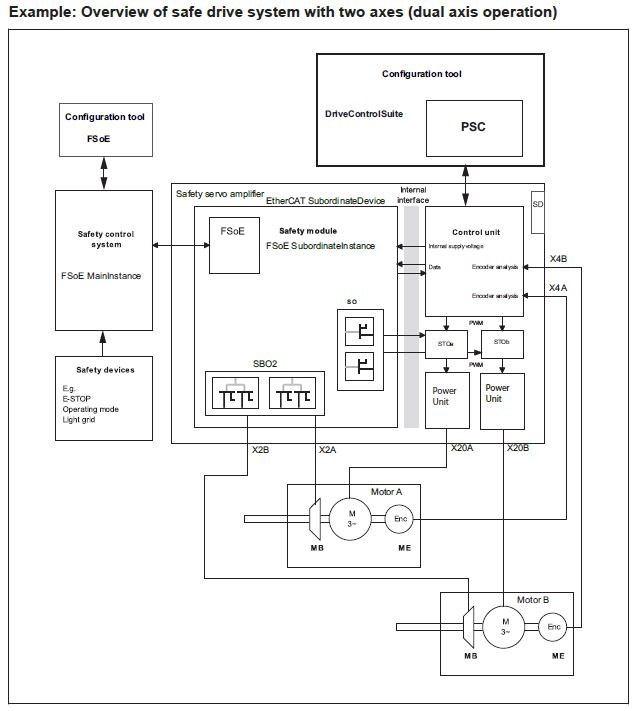

With the SX6 safety module, the SI6/SC6 servo controller can be incorporated into the safety circuit as a “safety related part of the control system” (SRP/CS) for the execution of safety functions (Safe Drive System).

Safety functions (configurable)

Connections

EtherCAT FSoE interface

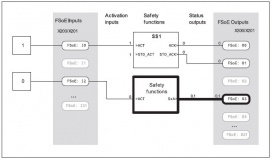

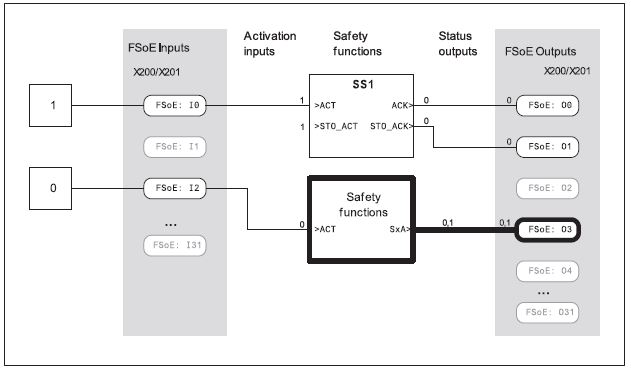

The safety functions can be assigned to the freely available inputs and outputs (EtherCAT FSoE status/control bits) in the configuration tool of the safety module.

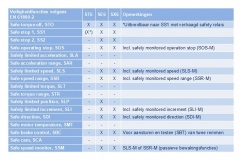

The table below shows an overview of the safety functions according to EN 61800-5-2 and which of them are available with the SX6 safety module. The mentioned ST6 and SE6 are the safety modules that are available for the Stöber SD6 controller.

Safe Drive System structure

A Safe Drive System consists of the following as standard:

Optionally can be added:

The Safety module SX6 (depending on the configuration):

The Control Unit:

The Safety control system (safety PLC)

The PASmotion configuration tool:

Example of activating the safety function (SS1) with error detection by status feedback:

Pilz PASmotion software tool started from Stöber DriveControl Suite

Example of configuring the Safe Operating Stop (SOS) function in PASmotion

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.