2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

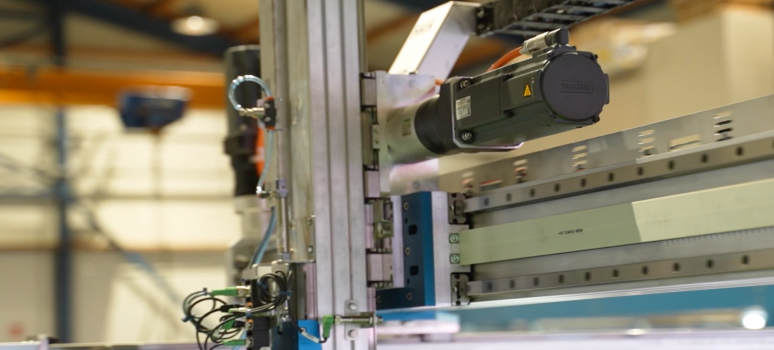

HSB XYZ-systems

Custom made complete solutions in 2 or 3 areas comprising the HSB positioning tables and linear units.

The ATB Automation project team designs and commissions complete linear systems to customer specifications. The basis are HSB linear units in combination with stepper motors, servo motors and possibly motion controllers. In most cases ATB Automation also takes care of the electrical installation and programming.

Including mounting plates and adapters.

Including couplings and line shafts.

Two gantry robots for a repacking line with a working range of 2200 x 2030 x 1900 mm in the X-Y-Z plane where crates are stacked. The capacity of the stackers is calculated on crates of 10 kg and 6 cycles/min. There is also a product transfer unit in the repacking line with a working area of 1700 x 600 mm for handling rejected products.

The basis of the systems are the robust HSB portal axles from the Gamma series with double recirculating ball guides and toothed belt transmission. Due to the limited installation height, telescopic axes for the Z-movement have been used here. The linear modules are equipped with our Stöber planetary gearboxes, flexible for mounting any type/brand of servo motor.

Portal robot with a working range of 7600 x 400 x 2500 mm in the X-Y-Z plane where solar panels are stacked.

The HSB portal axes from the Gamma series with double guides are the basis of the system.

The X-Y-Z movements are performed with Trio servomotors and Wanshsin planetary gearboxes.

At the bottom of the Z axis is a 3D manipulator driven with the compact servo motors. The mass of the grab and the solar panel, a total of 75 kg, hangs on the Wanshsin planetary gearbox from the WAD series.

Interpolation of the 3D manipulator and the XYZ system is done with the Trio MC4N motion controller. The Estun servo controllers are controlled from the Trio control via EtherCAT control based. The Trio motion controller has been extended with a Touch Screen and additional I / O modules (Trio EtherCAT Flexslice system) for the complete machine control.

Conducted by the project team of ATB Automation.

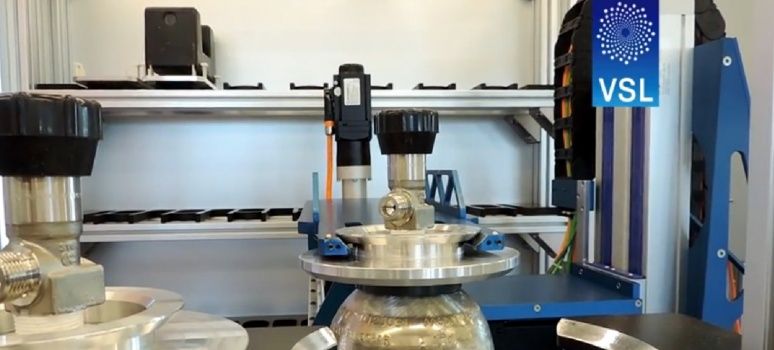

A system composed of XYZ HSB Delta-S linear units with spindle and Stöber EZ-servo motor (X and Z-axis) and HSB-Beta Z linear unit with a toothed belt and Stöber PE-EZ planetary servo motor gear. The system is able to move gas cylinders of 20 kg within a reach of 1000 x 300 x 1000 mm, without external guides.

Central control is the Trio MC4 controller with Delphi communication via OCX commands. The Trio controller controls the Stöber SD6 drives via EtherCAT.

Manual testing of often hundreds of components in the circuit board is replaced by a XYZΦ-positioning system in a PCB scanner. The test time is halved thanks to the speed and accuracy of the machine. The risk of skipping components during the test is nil.

Fully automatic laboratory based on a 3-axis servo system for sample analysis in the minerals industry. The pick and place system with a stroke of nearly 5 meters is PC controlled. The control cabinet is designed and implemented by ATB Automation.

Rail or roller guide in an alu-profile, closed with a cover.

Within the range of the Beta and Delta or Gamma and Sigma modules ATB Automation calculates and selects each gantry

ATB Automation delivers on project basis total solutions with servo systems and controllers.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.