2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

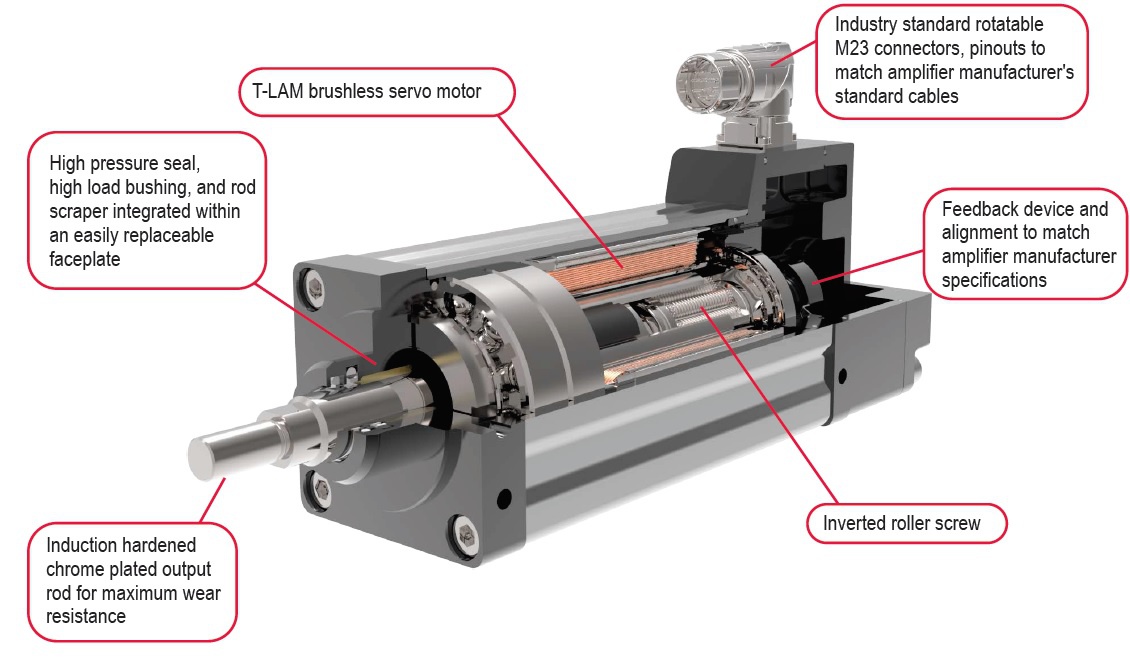

The GTX actuators from Exlar are brushless ac servo motors fitted with an inverted roller screw in the rotor. As a result, the linear transmission is integrated in the servomotor.

The GTX series is available in 3 frame sizes with flange dimensions of 60, 80 and 100 mm.

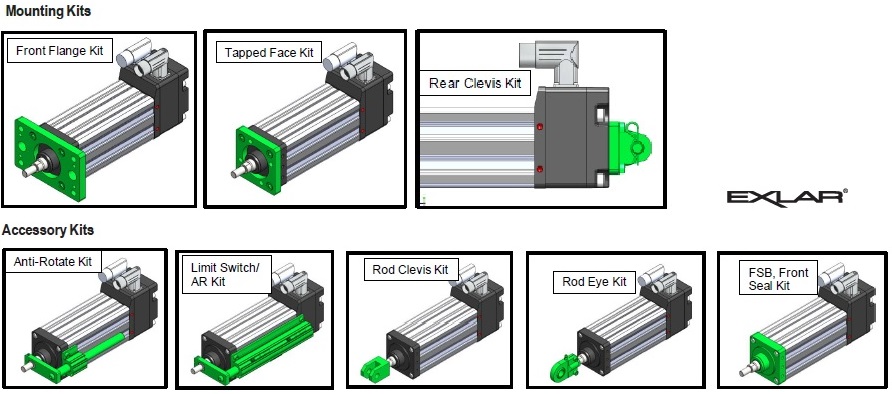

The compact basic actuator can be easily expanded with various options for mounting in the machine.

The GTX is available with resolvers or absolute encoders for suppliers such as B&R, Bosch Rexroth, Siemens, Rockwell Automation and many more. The connectors and pin-out are suitable for use with standard cabling from the relevant supplier.

ATB Automation supplies total solutions in combination with Stöber servo controllers and cabling.

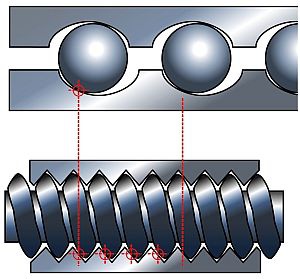

A roller screw is a mechanism for converting rotational torque into linear force and motion. Several helical threaded roller screws are assembled around the linearly moving axis as a planetary system. Compared to other transmissions, a roller screw is very powerful with a long service life. This makes a roller screw actuator the ideal choice for demanding applications with continuous operation.

By design, the number of contact points in a ball screw is limited by the size of the ball. Exlar's planetary roller screw design provides many more points of contact than is possible on a comparably sized ballscrew.

As a result, a roller screw has a greater load capacity plus better stiffness. A roller screw also takes up less space to meet the desired load-bearing capacity. The Load Capacity factor (Cdyn) of roller screws is 2 to 3 times higher than ballscrews of equal size and therefore gives an expected service life of up to 15 times longer.

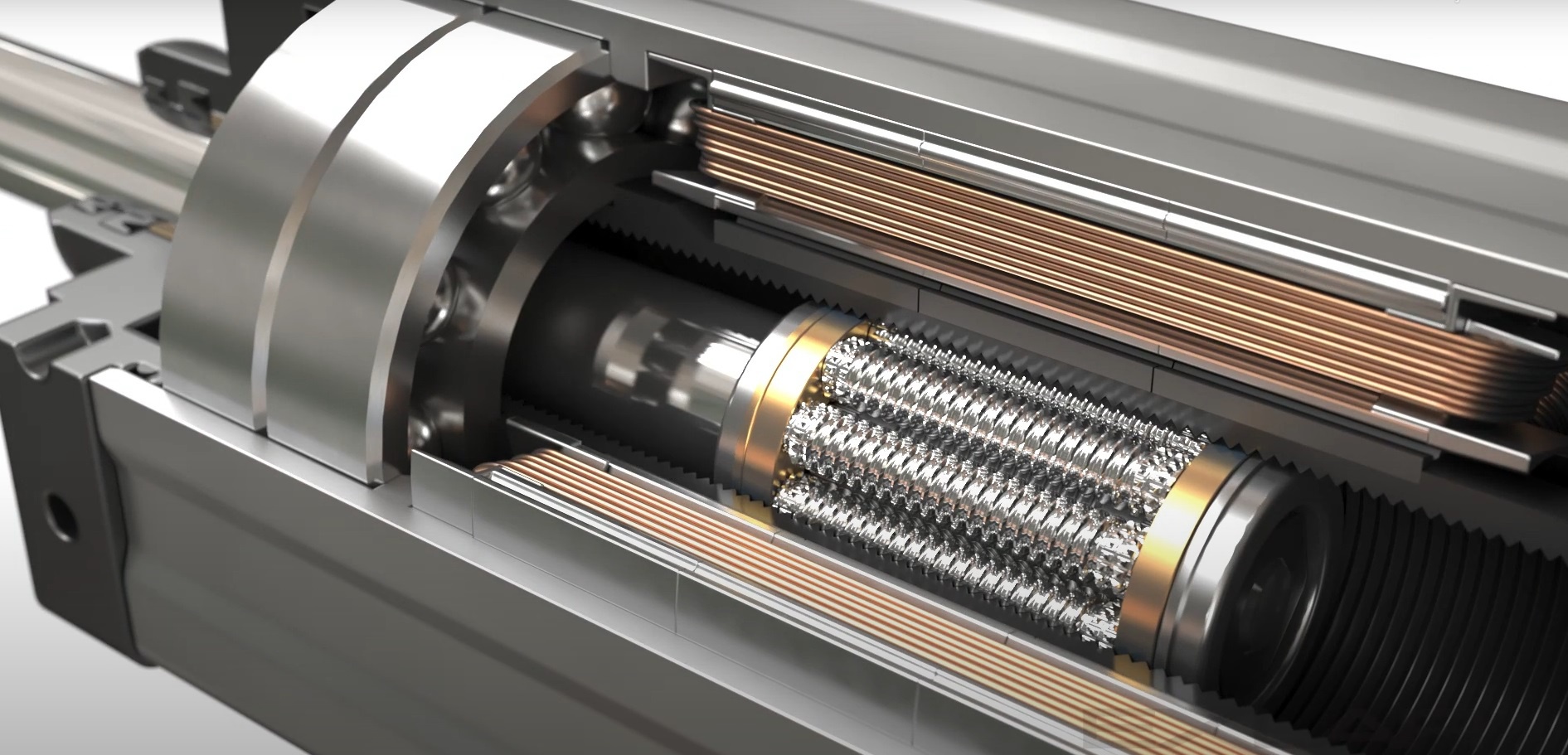

View of the rotor with inverted roller screw. See below the video with the operation of the GTX servo actuator.

In the production of marshmellows, the product is chopped by means of a knife driven by the Exlar GTX servo actuator. Due to the roller screw transmission, the actuator is suitable for a high duty cycle and a long service life is guaranteed. The actuator is equipped with an encoder suitable for control by the Stöber SD6A servo controllers.

With this GTX80 actuator, forces of up to 2 kN can be achieved in combination with a speed of 1100 mm/s.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.