2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

Date: 27 May 2015

Rosta is well known in general engineering with rubber suspension units and its numerous applications. Rosta is also often used in the food industry as maintenance-free spring element. PIM Machinery is such an example. They are a very satisfied user of Rosta tensioning elements in their vegetable weighing machines and packaging machines.

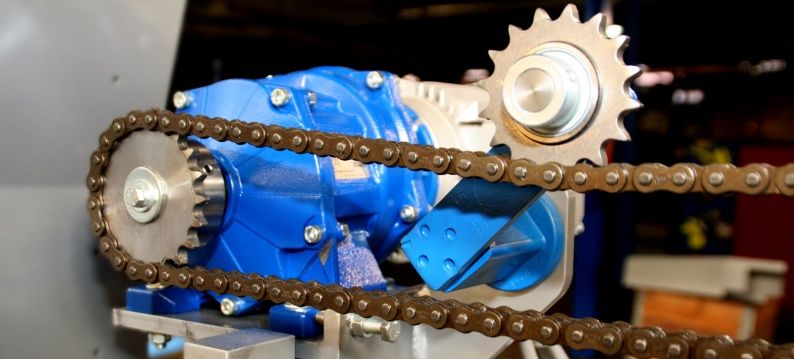

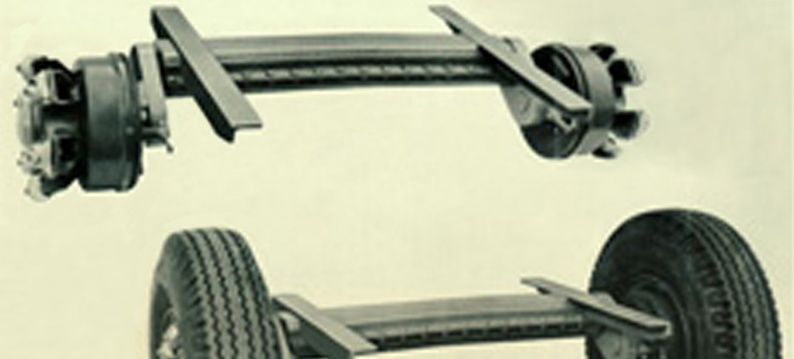

Rosta rubber suspension units were originally built around 1942 as a space-saving rubber suspension for trailer axes. This maintenance-free suspension unit with longevity is designed for loads from 250 kg to 5,000 kg. Later Rosta continued to develop the rubber suspension units for use in general engineering applications. Suitable for tensioning chain drives and belt drives, suspension of feeders, screens and conveyors, and as mounting and damping.

Machinery PIM gratefully uses this continued development of the rubber spring elements. They are reknown as producer of the most accurate vegetable weighing machines and vegetable bag sewing machines. "The choice for the high quality and the longevity of the Rosta chain tensioners in such machines is therefore quite obvious," says René Buunders, project manager at PIM Machinery. "In the greenery machines the chains of the main shaft run continuously. After weighing, the vegetables are packed in the bags sewing machine. There we use a Rosta chain tensioner for the gripper, and two Rosta chain tensioners for the drive of the V-belt. The Rosta tensioner plays an important role in both machines for accuracy. As we cannot afford to slackening of chains or wearing."

» Website PIM Machinery

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.