2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

Date: 23 October 2013

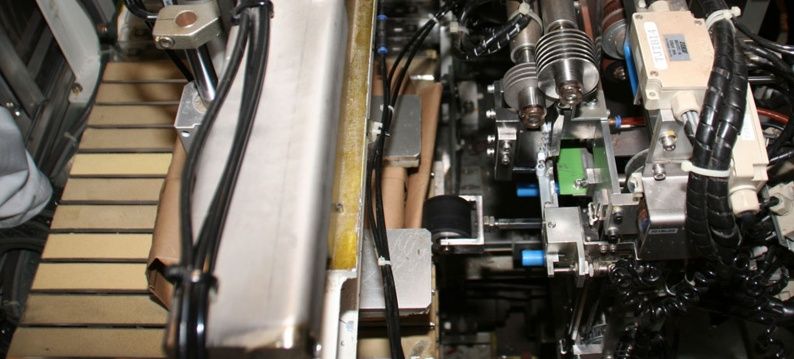

Wrapping photopaper rolls in a lightproof packaging requires attention. Therefore Fuji Photo Film Manufacturing Europe BV in Tilburg again chose IAI electric actuators. "These actuators are the stable and accurate factor in this packaging machine," explaines electrical maintenance engineer Jeroen Aarts. "Pneumatic cylinders are less accurate than electric, because they are going to vary due to leakage and variation in tuning. The IAI servoactuators have an exact speed and can easily be adjusted for different product variations."

IAI is the logical choice: "After 15 years of loyal service without any maintenance, the IAI electric actuators certainly proved their reliability to us. Moreover, thanks to their compactness they fit in the tight space. And we have experienced Mijnsbergen as a reliable partner. They have a lot of knowledge where you can always rely on."

"In 1997 for the construction of this packaging machine IAI electric actuators were chosen. Especially the available installation space for the actuator, the movement of the pressroll to seal the packaging, is very tight. The compact IAI actuators just fit right. Because of the demands of our product and production process, since installation 15 years ago we have had no lubrication maintenance or cleaning of the actuators. Yet, they worked trouble free all the time. For the production reliability we now decided to replace the most critical actuator."

"The IAI actuators are used for all movements which are difficult to achieve with air cylinders. The packaging machine produces different types of products in one line. With air cylinders you are bound to fixed positions. Using the drives of the electrical actuators, we can program the actuators depending on product at speed, position and profiles."

"The drives are incorporated in a special lightproof switch-box that is shielded. The photopaper may not be exposed to any form of light during the packaging process - that therefore takes place in a completely dark production facility. Any kind of status LEDs in the process will damage the photopaper. This actuator does not have any light sources, and could therefore be used without any modification in the machine."

>> To product IAI RCS linear electric actuator with servomotor 230V

For questions about IAI electric cylinders or potential applications, please contact us, or use the contact form below.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.