2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

Date: 24 January 2024

“While in the past a lot of work was done with hydraulics and pneumatics, electric propulsion has taken off in recent years. We closely monitor these developments, which allows us to offer customers added value,” says Rico Godfried, mechanical engineering manager at ATB Automation.

With branches in Belgium and the Netherlands, ATB Automation has been selling drive technology and motion control components from various renowned brands for more than seventy years. “The areas of application are extremely broad. We supply components for the manufacturing industry, steel industry, automotive, food industry, but also for moving stages used in theater halls. In short, we have components in our range for almost all applications that involve movement, from clevises and rod ends, gearboxes, positioning systems, servo technology, couplings to worm gears, and so on.”

The extinguishing turbine on this fire truck is lifted using four NEFF lifting spindles, supplied by ATB Automation.

During Indumation, ATB Automation will showcase the latest products and components on 60 square meters with a large team. Rico Godfried gives us a glimpse of the veil: “We are there with renowned brands in the field of Mechanics and Motion Control. Think of TANDLER gearboxes, Rosta rubber spring elements, and servo systems from Stöber and Leadshine. Various demos of this will be on display at our stand.”

Within the Mechanics group, lifting spindles are also an important product group. “We offer solutions for various industries with lifting forces up to 500kN. One of the brands we will be exhibiting at the fair is NEFF Gewindetriebe. Their spindle lifting elements are of high quality, while communication with this supplier is very close. The company has many production processes in-house. For example, they also produce their own spindles, which not every manufacturer of lifting elements does. This leads to high quality and a better grip on the whole, compared to players who outsource the processes or parts of them. In addition, NEFF Gewindetriebe is a family business. This means they pay attention to their own staff, while also daring to invest in innovation. They are currently expanding their production location and are also implementing new developments, such as telescopic spindles, which can be interesting for applications in smaller spaces.”

The C series from NEFF can also be supplied as a telescopic spindle.

ATB Automation offers more than just components. “We also look at the applications and purpose of companies. We see that interest in electric drives has grown strongly in recent years. The great thing about NEFF lifting spindles is that you can drive them not only by hand, but also with electric motors. ATB Automation consists of both the Mechanics department and the Motion Control department, which makes it easy for us to make the right combinations. The advantage of this is that, if a customer wants to combine a lifting spindle element with an electric motor, we can easily check from our Motion Control range which motor and additional control components best suit the customer's application, in order to create one whole. to make. It is important for us to have short lines and to be quick to our customers. That is why we also have a branch in Belgium.”

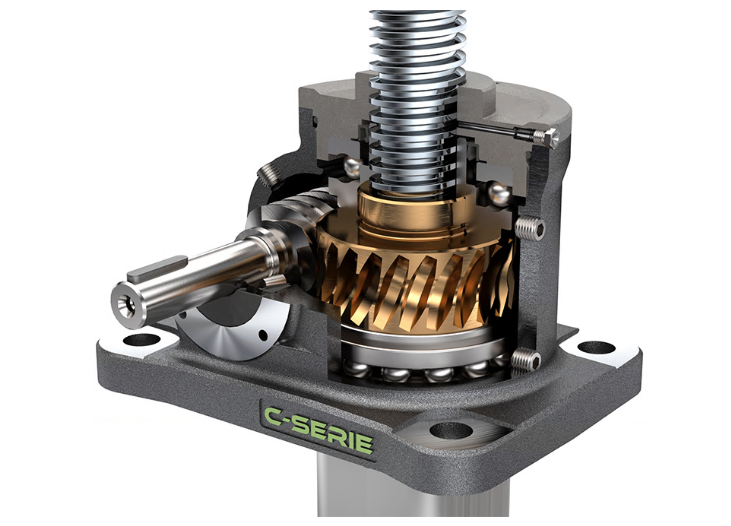

An open image of the C-series spindle lifting element from NEFF.

“What we notice is that it is sometimes difficult for customers to select the right components, especially when it comes to configurations of different lifting and spindle components,” says Rico Godfried. “Customers are not always aware of what is beneficial for the whole to be incorporated. I see it as a puzzle for advanced users. You can save space by installing components more intelligently. We can therefore advise you to arrange spindles smartly. We provide tips that contribute to cost savings. And that leads to a win-win situation.”

Text: Evi Husson

This article is a publication from industrialautomation.be.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.