2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

Date: 27 August 2014

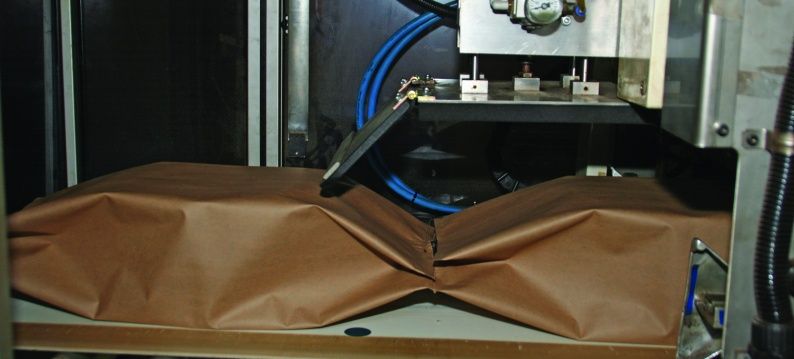

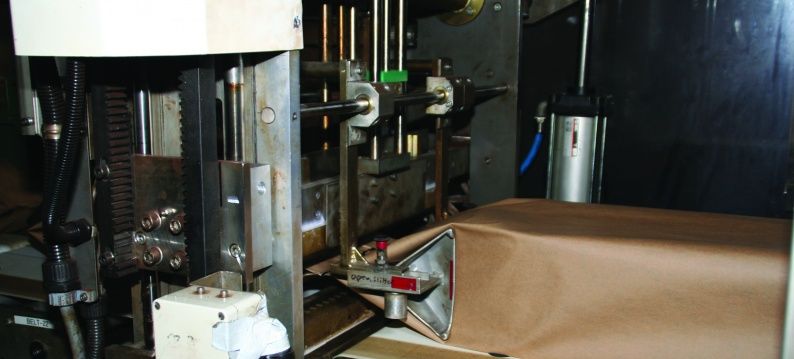

Fuji Photo Film has replace old servo drives in a 20 year old photopaper packaging machine by modern Stöber servo drives. A beautiful job, completed by our project team and as a result a satisfied customer.

Peter Hamersma, project manager at Mijnsbergen - ATB Automation says: "All these various sizes photopaper rolls have been packed lightproof for more than 20 years with this machine. Early 90s these packaging machines were equipped with analog servo controllers from Stöber. Fuji now wanted her machinery up-to-date with the latest generation drives, which are readily available. Therefore, they have asked us at the end of 2012 to do an inventory of this packaging machine. The aim was to modernize the entire machine control, consisting of 12 servo drives. A nice job for our project team, exactly matching our approach.

When our customers require a complete motion solution from us, we always make a thorough assessment of the customer needs. Important here is what the required result should be and the agreements of who-does-what. This results in a project design which is discussed with the client and with which we get started on with a fixed price. Such a project design gives clarity with a clear and feasible planning, from engineering up to delivery and commissioning.

In the packaging machine, the seal motion is executed with a flying saw. Early 90s a remote controller with a separate encoder was required for this. Our analysis showed that the old controller in combination with the old drive could be replaced by one servo drive from the Stöber SDS5000 series. This drive includes all the motion functionalities required for a flying saw application. We coul easily exchange the drives, consisting of servo motors and gear units, because the connecting dimensions of Stöber have remained unchanged during all those years. Further, the drives have become more compact.

With proper preparation, including writing and testing the software, we have realized the mechanical retrofit, installation of the electronics and commissioning of the first three drives within two days. Everything exactly according to plan. Meanwhile, the drives have run a few months now and the plan for the next conversion of the remaining drives is ready. For Fuji, it was important that the project was implemented exactly as planned during the production stop and then immediately the full 100% production could be continued. Together with Fuji we look back at this project full of pride and satisfied."

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.