2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

Date: 10 November 2017

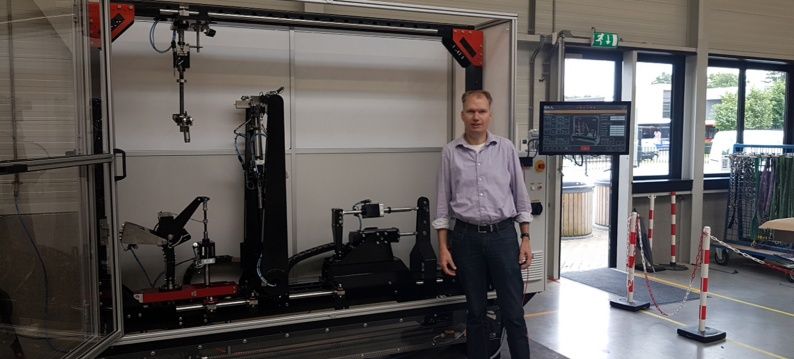

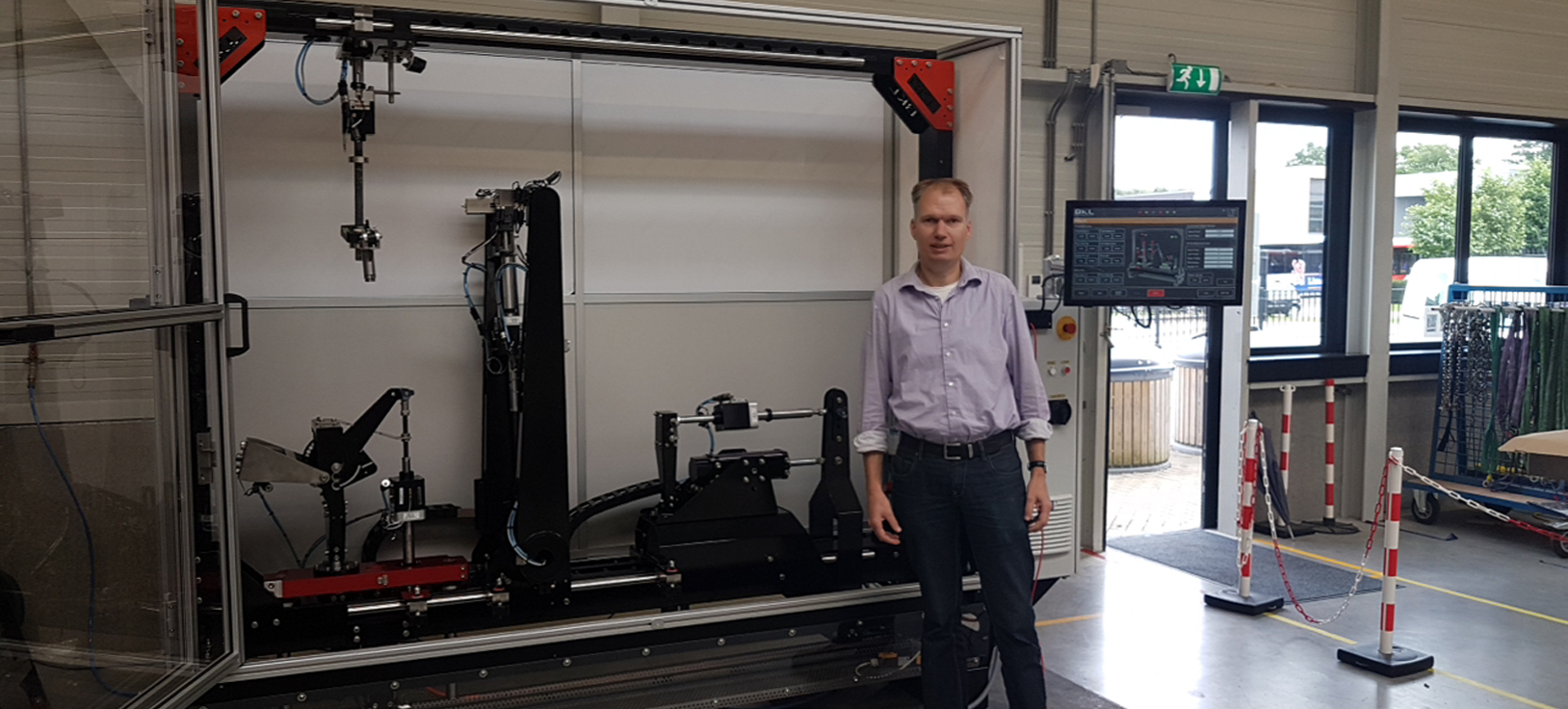

Before a bicycle is sold, there are a lot of tests to ensure the safety of a bicycle. BKL Engineering has been working on a testing machine for bicycle frames on a long-term. This sytem ensures that the quality of a bicycle frame is determined by stiffness and elasticity.

BKL Engineering received a nice challenge from a customer. For testing the frame of a bicycle a test rig had to be developed and built. This test rig must be able to carry out various test concerning the rigidity of a bicycle frame. Important for the customer is also the service and aftercare, as the test system will ultimately be completed in various parts of the world.

On one level

Every project is different and BKL Engineering is therefore looking fort he right components. For example, fort his project BKL Engineering has been looking for a supplier that could help them with good and durable electric actuators. Important in making this choice was that in addition to the delivery of the components, this supplier could also advise on the project. A good advice about dynamics, life time and the control circuit of the drives was crucial. Besides that good support and service throughout the development process are very important. They found all this at ATB Automation, so the first contact was created. "We found the right partner in ATB Automation," says Paul Postma (Project Manager at BKL).

‘BKL Engineering is a project organization and with 4 words they know what you mean at ATB Automation. Because of the open and personal communication at ATB Automation we have experienced the cooperation as a pleasant one and therefore we have done a nice project! "

The bicycle frame test test machine

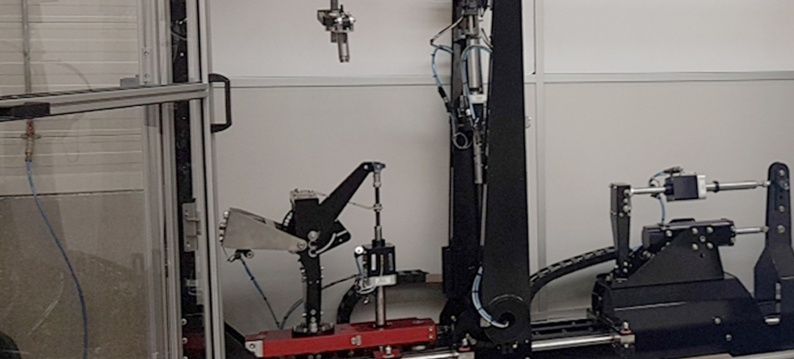

With safety shoes on we enter the workroom of BKL Engineering where the bicycle frame test machine and its operation is being explained to us. Different testsare being performed. Paul Postma says: ‘The norm is to hit 100.000 times against a curb, simulated by pushing against the front fork. The seat on the bicycle frame, the peda land brake loads are tested in the same way. These tests are all performed seperately, most tests take between 6 and 14 hours. The most important of the test machine is that the degrees of freedom of the interfaces of the bicycle frame can be adjusted automatically.

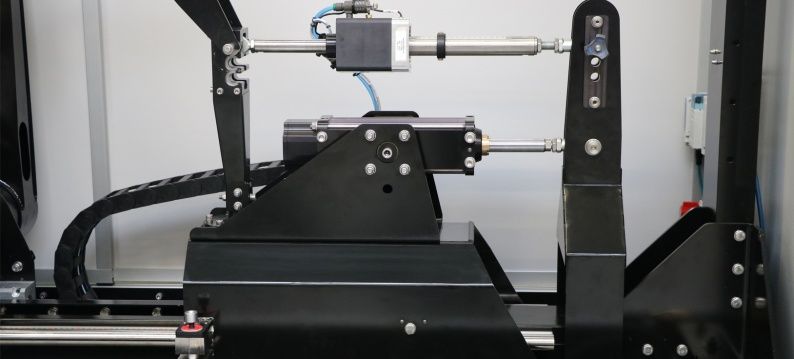

The starting point of the new test machine has been considered carefully. The existing machines were equipped with a lot of pneumatically driven movements. It is well known that pneumatic movements cost a lot of energy. In fact, you always throw away air. This is also a fairly cost item. "The customer wants to be a green company as a bicycle manufacturer," says Paul Postma. The air consumption was significantly and the wastage of the components only increased. The system also had to be more dynamic than the existing test systems. It was important to get a good advice on the stroke frequencies of Exlar linear actuators. Based on the calculations, the choice of lineair actuators from the Exlar GSX series has been made. This compact roller screw servo actuator is very powerful and has a high lifetime, which makes this actuator the ideal choice for this demanding durability test. Besides the reliable Exlar actuator, ATB Automation works with Stöber's highly fast and accurate Digital SD6 servo controllers, which seamlessly connects to BKL Engineering's control.

Who is BKL Engineering?

BKL is a technical service provider in mechanics and mechatronics. We develop high-quality solutions enabling clients to work smarter, more efficiently and above all more safely: hoisting and lifting tools, industrial modules and machines. Our range of services include engineering, inspections, services and manufacturing. We provide services for partial processes and overall solutions.

Your safety, our DNA

The users of your hoisting and lifting tools, modules and machines are your employees, your human capital. Their safety is of paramount importance. That is why we develop machines that can be operated easily, are user-friendly and enable safe working. Moreover, a safe working environment for your employees encourages their sense of enjoyment and commitment; it reduces the chance of incidents and supports continuity.

High-tech solutions

On a daily basis, a team of forty experts work on inherently safe solutions. We operate throughout the world and we are OEM.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.