2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

Date: 7 April 2015

Exlar produces widely applicable electric linear actuators. Tthanks to the "power" of the Exlar roller screw servo actuator, this is an excellent replacement for pneumatic cylinders in many push and pull applications. For 3 years already, HTMS Mechelen benefits of the advantages of electric actuators versus pneumatic. The Exlar electric actuator has performed the optimal linear motion in their cutting machine these past three years.

With a warm welkcom Ruud Ilegems, technical service of HTMS, showed us their spacious production room and expalins: "The cutting machine is used to cut metal strips for our final product. Previously this was done manually. With the Exlar electric actuator we have automated this process. Of course we also first thought of a pneumatic cylinder. Nevertheless, that has a number of drawbacks for us, which we do not encounter with this electric cylinder. We have a lot of machines in the production area. With these Exlar electric actuators, we limit the noise level in the production environment, because they produce much less noise than pneumatic cylinders."

Ruud Ilegems indicates that in addition also the flexibility of the Exlar electric actuator was an important decision criterion for them. "The Exlar servo actuator is much faster, easier and more flexible set up than pneumatic cylinders. Commissioning them was very simple. If any questions arose, the ATB employees were always immediately available to us."

In the cold forming machine, HTMS also placed an Exlar servo actuator. Both machines are linear pushing and positioning applications, where the qualities of Exlar servoactuators are put to their best use. That is; they deliver a high force and can be set up easily and precisely.

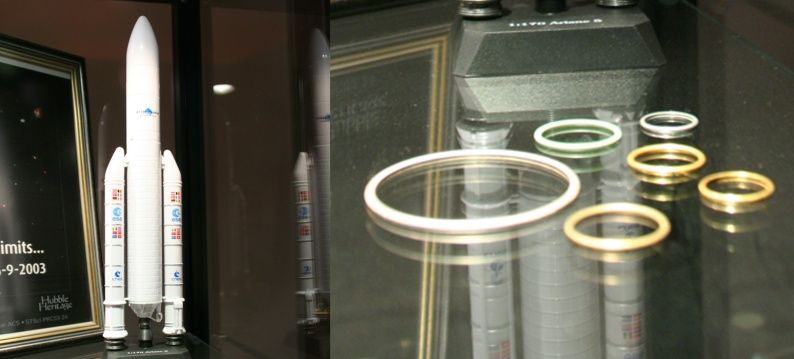

The sealing specialist HTMS in Mechelen produces high-tech metal seals for, among others, aerospace and petrochemicals. More information can be found on www.htms.be.

» Exlar Tritex II servo actuator:

230V brushless servo motor with integrated roller screw, amplifier and positioning control.

Do you also have a push or pull application? Inquire about the possibilities and advantages of Exlar servo actuators »

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.