2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

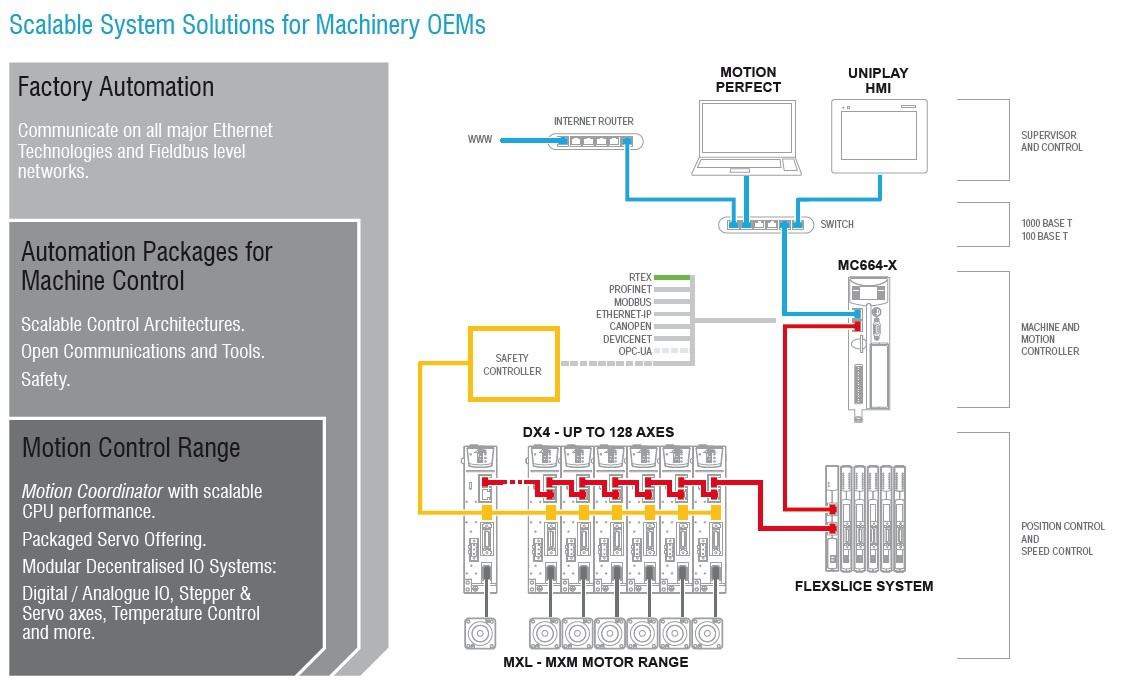

The DX4 is designed to work seamlessly with Trio's EtherCAT controllers and be fully integrated into Trio’s application development tool, Motion Perfect allowing complete machine configuration from one tool; commissioning, diagnostics and programming.

Trio provides total solutions with the Trio EtherCAT motion controllers for central control of up to 128 DX4 servo controllers.

The DX4 drives are equipped with integrated safety with the standard STO input (SIL3/PLe).

In addition, they are equipped with 7 digital inputs, 4 digital outputs and a 2nd enconder input.

The DX4 is used with the Trio MXL and MXM servo motors from 50W to 3 kW.

Portal robot with a working range of 7600 x 400 x 2500 mm in the X-Y-Z plane where solar panels are stacked.

The HSB portal axes from the Gamma series with double guides are the basis of the system.

The X-Y-Z movements are performed with Trio servomotors and Wanshsin planetary gearboxes.

At the bottom of the Z axis is a 3D manipulator driven with the compact servo motors. The mass of the grab and the solar panel, a total of 75 kg, hangs on the Wanshsin planetary gearbox from the WAD series.

Interpolation of the 3D manipulator and the XYZ system is done with the Trio MC4N motion controller. The Estun servo controllers are controlled from the Trio control via EtherCAT control based. The Trio motion controller has been extended with a Touch Screen and additional I / O modules (Trio EtherCAT Flexslice system) for the complete machine control.

Fully automatic laboratory based on a 3-axis servo system for sample analysis in the minerals industry. The pick and place system with a stroke of nearly 5 meters is PC controlled. The control cabinet is designed and implemented by ATB Automation.

A complete solution of ATB Automation has been used for cutting waffles.

Two servo driven lineair systems provide the input and output for plates of waffles. A third axis is used to print a cutting blade.

Central control is doe by the multi-axes Trio MC4N Motion Controller. The movements are recorded and matched in this controller. A Trio Uniplay display is being used for control. The Trio Motion Controller sends the servo drives real-time via the fast EtherCAT box.

The switchboard, programming and start-up of the system has been carried out by the ATB Automation project team.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.