2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

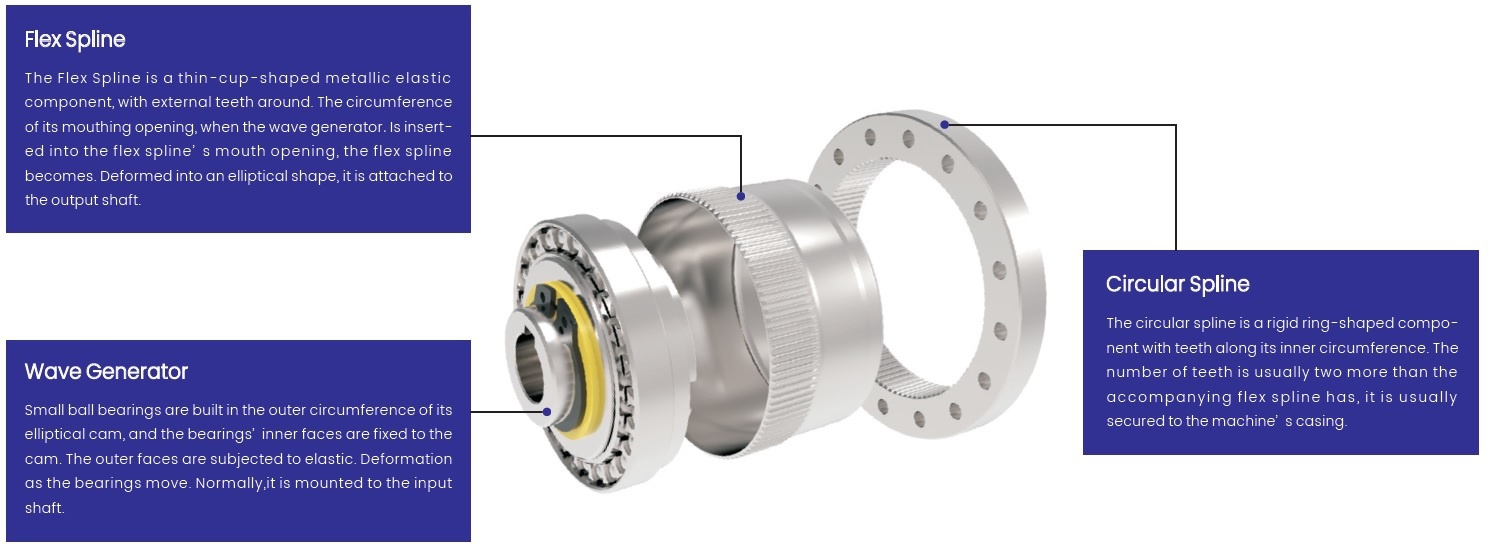

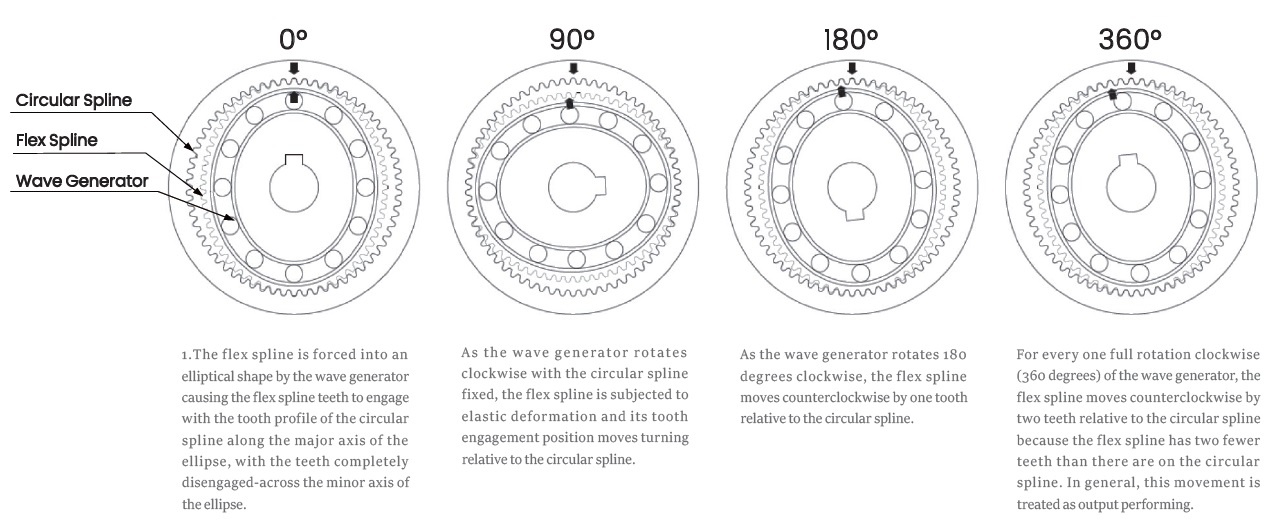

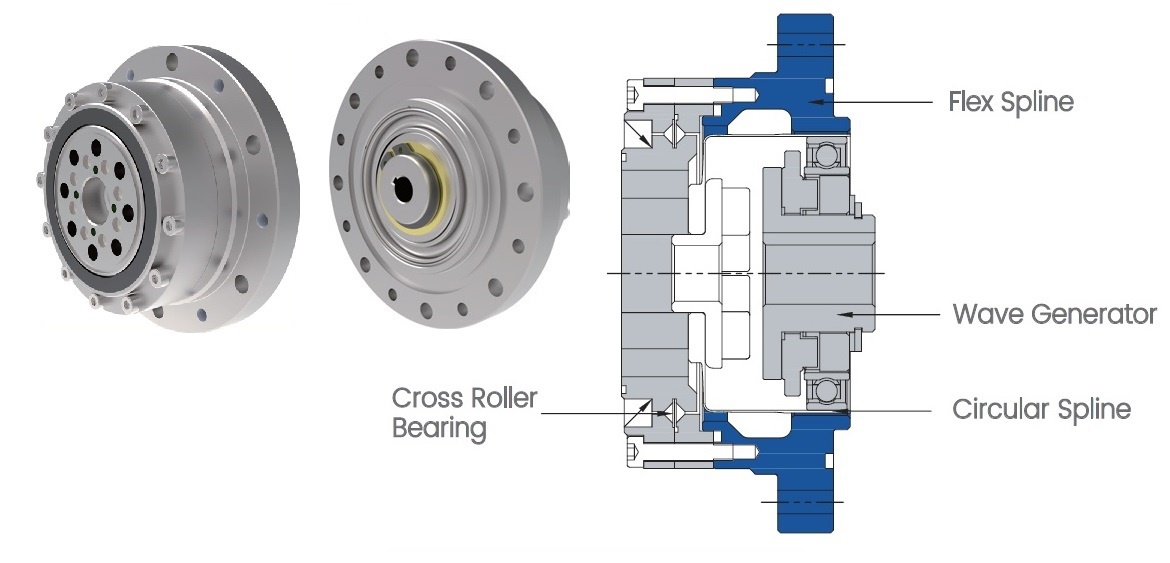

The WCSG series is a compact gear unit based on the Harmonic strain wave principle.

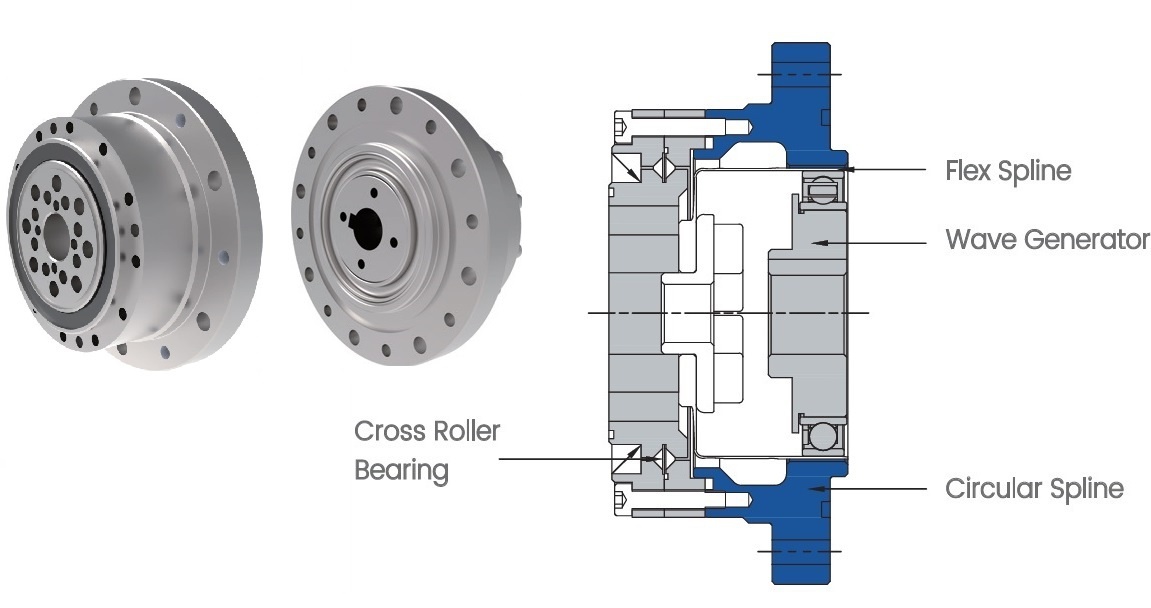

CSG gearboxes are housed component gear sets combined with a precision cross roller output bearing & flange. A highly rigid cross roller bearing is built in to directly support (output bearing) the external load. They are a very compact, robust and easy to use gearhead solution.

Generally, the circular spline end is fixed and the flex spline is the output rotating side.

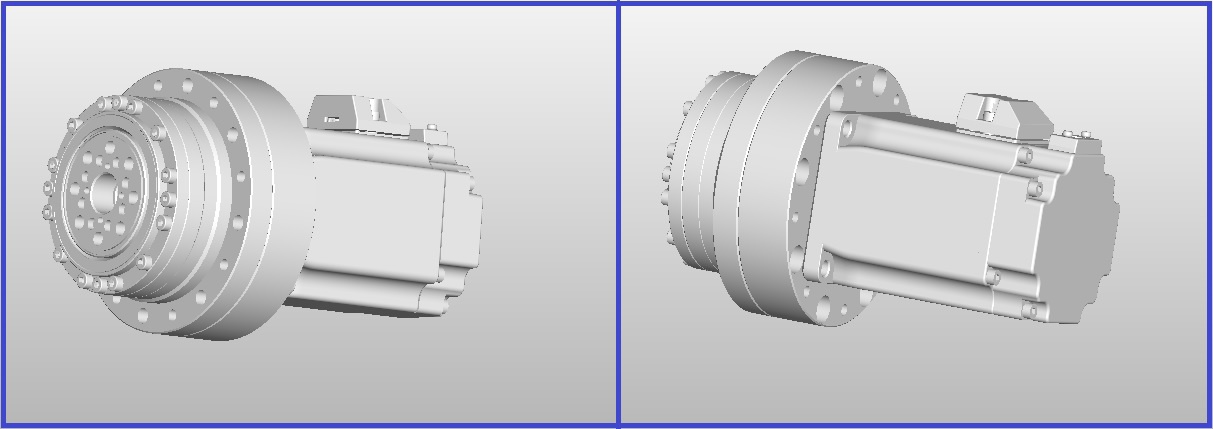

The WCSG series is available in 2 versions.

The input motor shaft is directly connected to the harmonic gear unit by means of a hollow shaft with keyway.

The input motor shaft is connected to the hollow shaft of the harmonic gear unit by means of a coupling.

The WCSG gear unit has the same dimensions and specifications as the Harmonic Drive CSG series.

In addition to the WCSG series, Wanshsin also supplies the WCSF series, interchangeable with the Harmonic Drive CSF series.

ATB Automation supplies these gear units in combination with adapters for servomotors or stepper motors.

Assembly of the gear unit with the servomotor can take place at ATB Automation.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.