2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

Compact linear spindle actuators with 24V servomotor with slide and absolute encoder. Ideal for replacing pneumatic cylinders.

Applicable in positioning function, possible in combination with a push-force function. Easy to commission with PC software or a hand control pannel.

Available controllers:

ASEL single or double axis programmable controllers (24Vdc)

- Free programmable

- 1500 positions

- Interpolation (2-axis version)

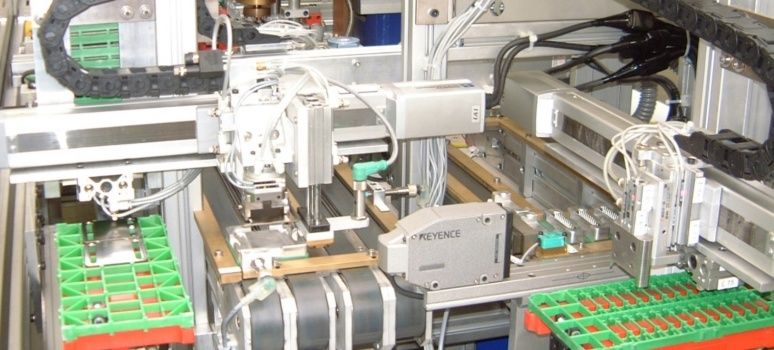

Production automation with IAI RoboCylinder actuators: plastic products are positioned and compressed.

An XY positioning table with two actuators with slider controlled by a 2-axis SEL controller.

The pressing of the products is effected by a ERC2-R RoboCylinder with integrated controller. In the controller is standard a push function that enabled to control the actuator by force.

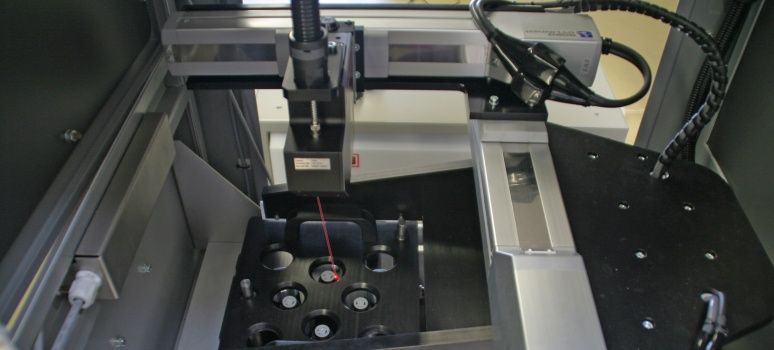

IAI linear units are used for an XY-laser welding unit which welds a range of products to each other using a spotlaser. The laser head follows the contours with a constant speed of preset diameters and a number of circular movements per weld. Via a touch screen, more products can be selected and changed.

The IAI actuators are deliverd with drive and cabling. Specifications of the actuator like forces and number of mm each revolution of the motor are already fixed. Because of this a a quick and safe commissioning is guaranteed.

The software engineers at ATB Automation assist in programming and commissioning via the help desk or on site

Besides control with I/O the drive can also be controlled with EtherCAT and ProfiNet.

The SD6 drive also has the CANopen option available.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.