2024

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

The Trio CAN16 Input/Output module offers a compact DIN rail mounted I/O expansion capability for all Trio Motion Coordinators. Up to 16 P319 modules may be connected to the CAN network which may be up to 100m long.

This provides 256 distributed bi-directional input/output channels at 24Vdc level. All input points are high level, (24V = ON) all outputs are short-circuit proof and the I/O is completely isolated from the CANbus.

P319 modules may be mixed on the same bus, with other types in the Trio CAN I/O range. The Trio CANbus I/O expansion can considerably reduce machine wiring.

Sub-project completed by the project team of ATB Automation. Positioning of an injection mold with IAI RoboCylinder actuators from the RCP-R series.

The complete control is programmed in the Trio MC405 motion controller equipped with various I / O modules and a 10 "touch screen.

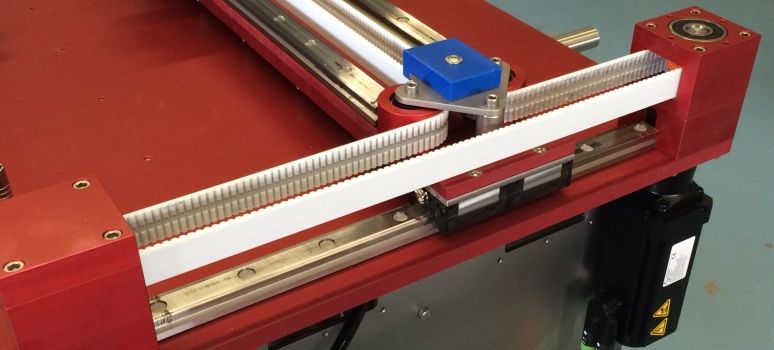

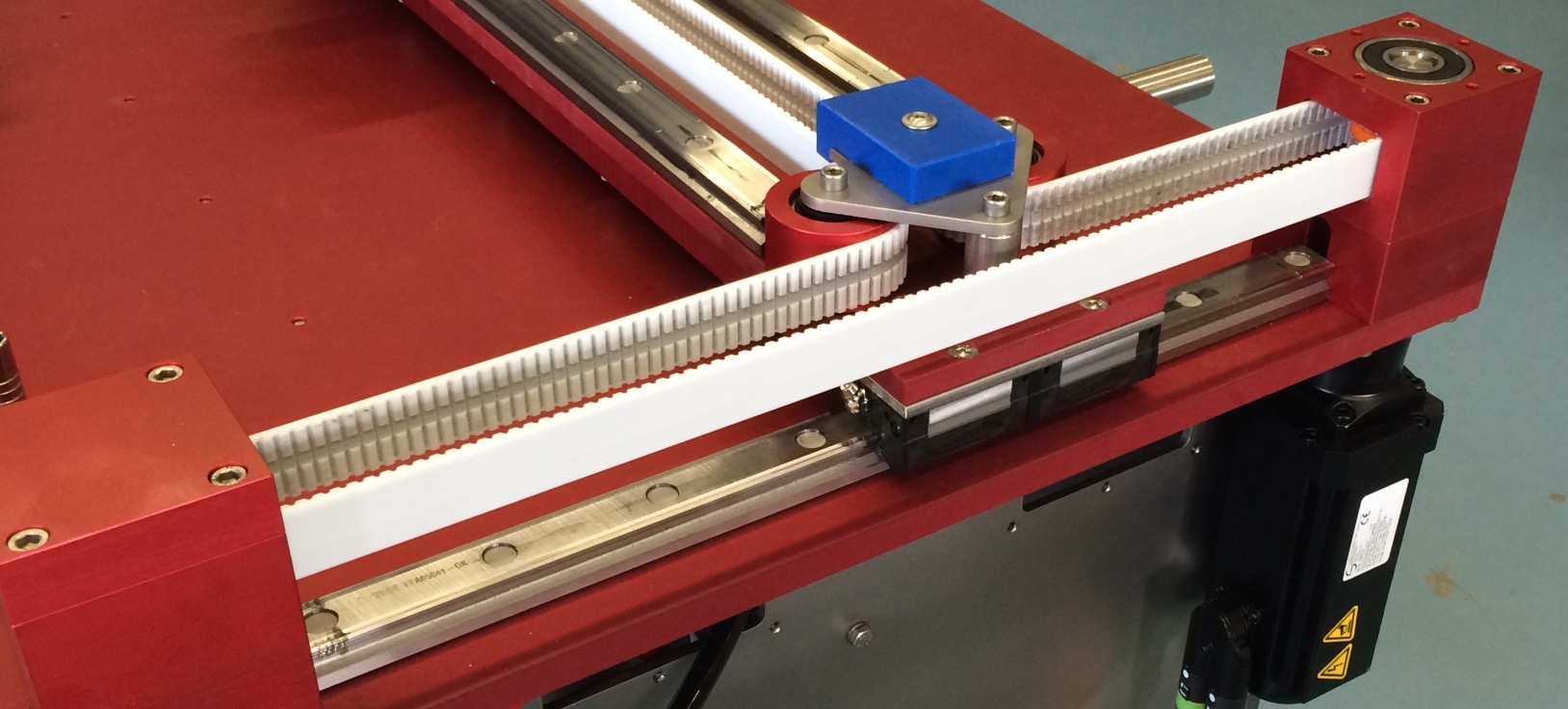

Single belt gantry system in the bakery industry: positioning of a spray installation.

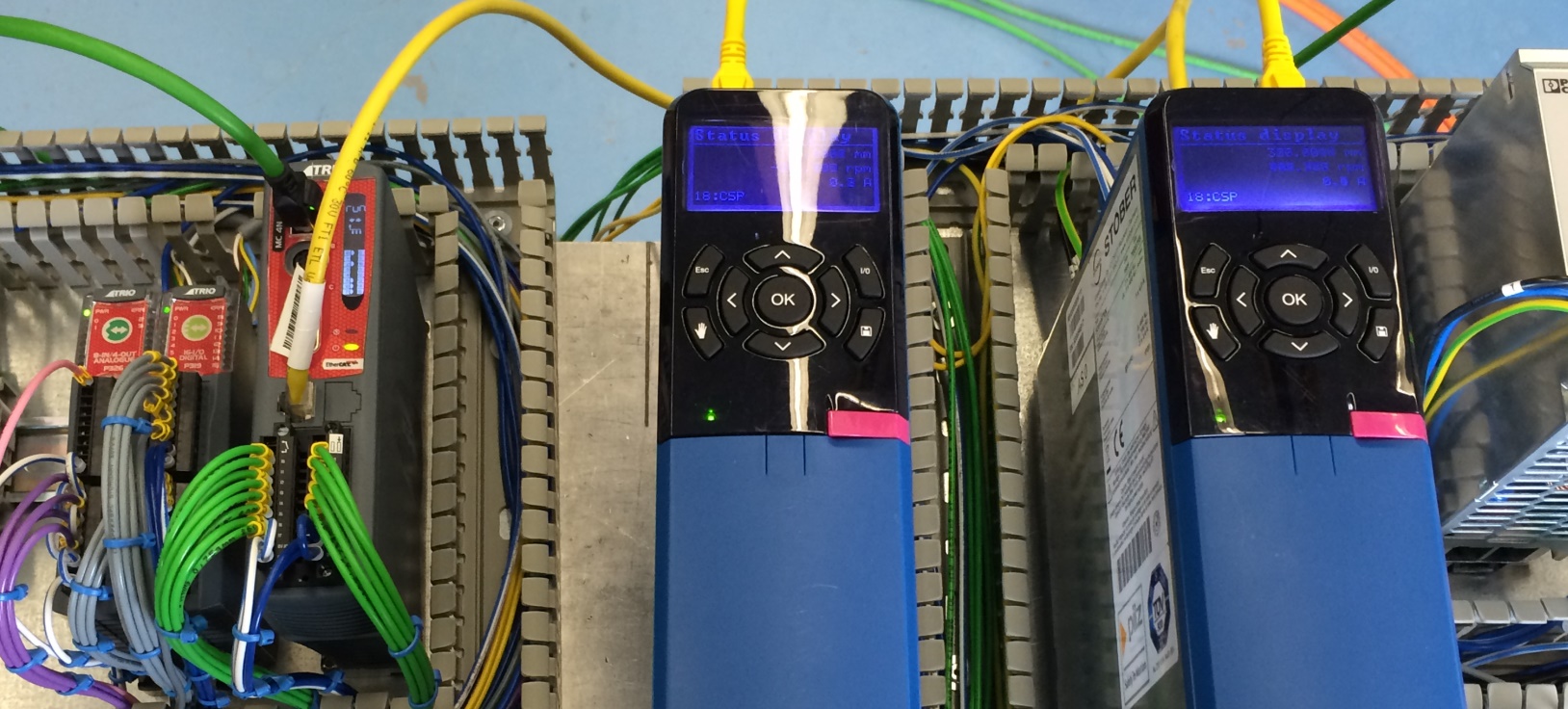

Stober servo system with Trio Motion Controller

The servo system and the control system is provided by ATB Automation. This consists of:

- Stober planetary servo drive, PE-EZ

- Stober servo controller SD6 with EtherCAT

- Trio Motion Controller MC4N with EtherCAT

- Trio digital / analog inputs and outputs

- Trio 7 "Touchscreen, UNIPLAY

Programming and commissioning project team of ATB Automation

In cooperation with the producer of the spray system the Trio MC4N Motion Controller is programmed by ATB Automation.

- Motion software with a gantry coordinate transformation, which makes the positioning easy in X and Y (mm) can be programmed

- PLC functionality programmed in IEC 61131

- Operating software in the control panel

The tuning of the servo system is performed by the specialists of ATB Automation.

This is all conducted according to an advance down project design and planning with a fixed price agreement.

ATB Automation: More than components

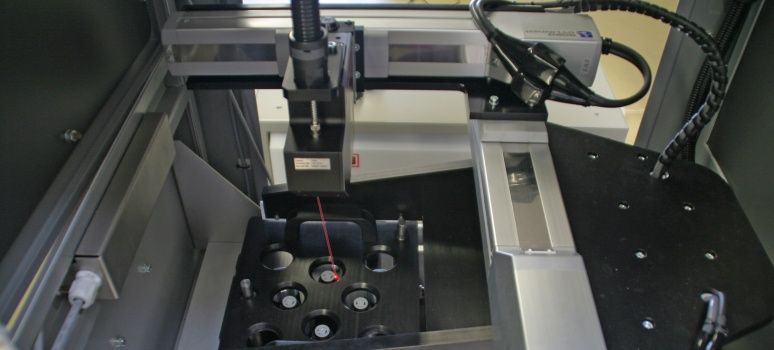

IAI linear units are used for an XY-laser welding unit which welds a range of products to each other using a spotlaser. The laser head follows the contours with a constant speed of preset diameters and a number of circular movements per weld. Via a touch screen, more products can be selected and changed.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.