2024

Servo à Vis à rouleaux linéaires versus actionneurs à vis à billes

Dans le domaine en constante évolution des avancées technologiques, la technologie des vis à rouleaux est devenue une force majeure dans le...

ATB Automation shares its 25 years of experience in Trio motion control projects by making a template available. The ATB Automation Template is integrated in MotionPerfect, the development environment of Trio Motion Technology.

Main benefits:

The ATB Automation Template will be made available after following the Trio introduction training. During this training, the design and the various options are further discussed and you can experience them yourself.

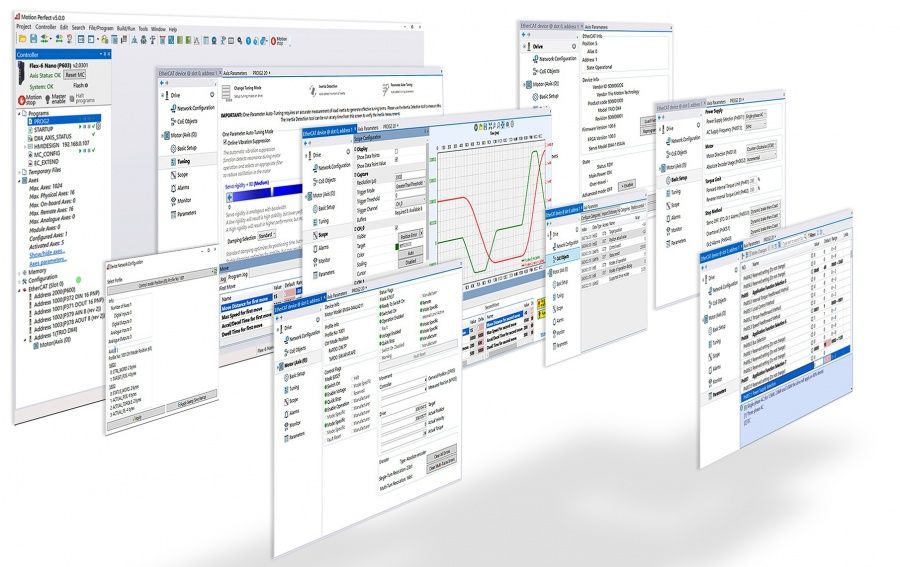

Motion Perfect is the development environment for the Trio Motion Coordinators range including the new Flex-6 Nano and MC6N-ECAT. It provides the user with an easy-to-understand Windows-based interface for rapid application development, controller configuration, and motion and controller function monitoring. In addition to the Trio MOTION-iX programming language, supported IEC languages and editor for HMI pages are available.

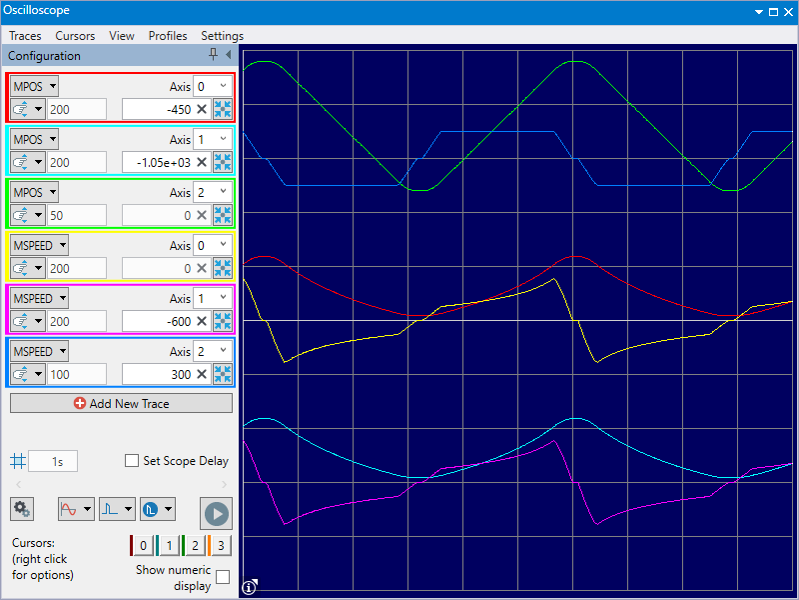

MotionPerfect also has a motion controller simulator and HMI Simulator program for offline programming. A 3D visualization tool is provided in the 2D / 3D oscilloscope to visualize the results.

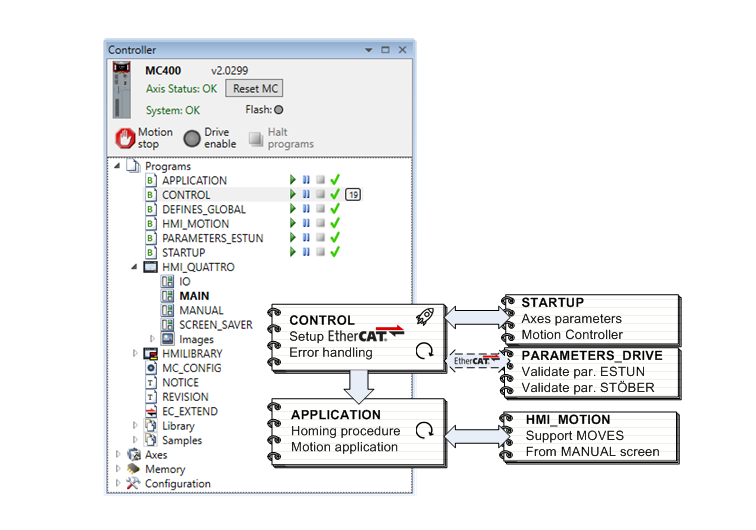

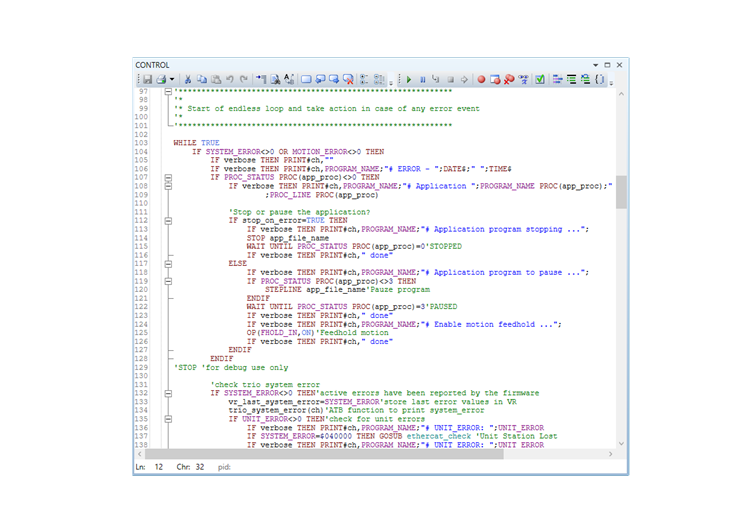

The template is made up of different Trio MOTION-iX programs, each with its own task. The CONTROL program starts automatically when the motion controller is switched on and ensures that the axes are provided with the correct parameters by running the STARTUP program. The EtherCAT connection is set up and checked whether all nodes are present.

Optionally, the drive parameters can be validated. The CONTROL program is always active to report and repair any system and motion errors. When all start-up conditions are met, the motion program APPLICATION is started. Depending on the application, it will first perform the reference procedure, after which the system is ready for production.

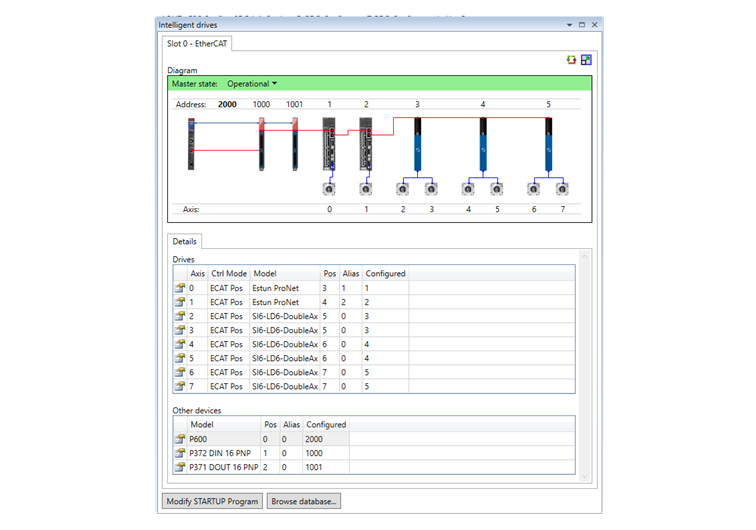

An EtherCAT configuration is provided within the template, so that position control is fully prepared with the brands Stöber and Leadshine. Other brands can also be added.

EC_EXTEND files have been prepared in the ATB Automation template, so that IO and measurement signals from the servo controllers are available in the Trio motion controllers and therefore also in MotionPerfect.

For example, inputs from the controllers can be used to connect, for example, the limit switches and / or reference switches and signals such as measured torque and tracking error from the controllers can be displayed in the MotionPerfect oscilloscope.

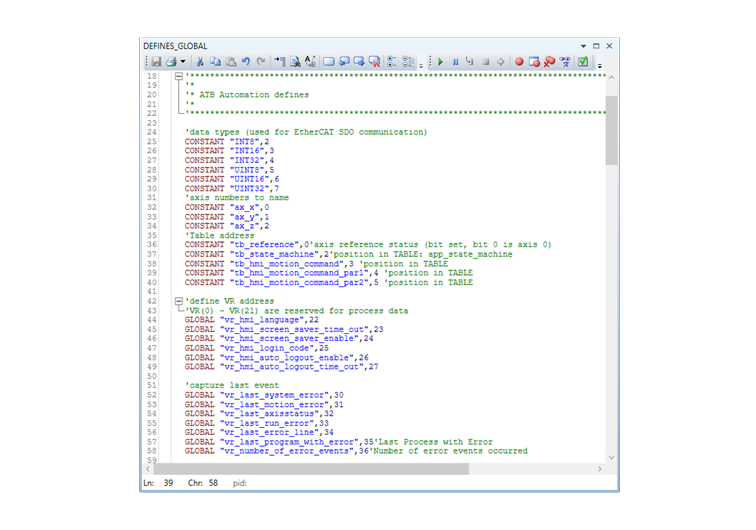

The template is designed with the “single point of energy” in mind. As a result, parameters only need to be entered at a single location and the first motion movement can be performed quickly. All application variables are entered in the Trio MOTION-iX program DEFINES_GLOBAL. And in the program STARTUP the axis parameters of the motion controller are defined.

Using the PARAMETERS_DRIVE program, it becomes possible to exchange a defective drive without having to manually load parameters. Make sure the drive complies with the default parameters when connecting. And all parameters required by the application are loaded by the Trio, after a single restart the drive is ready to use.

The heart of the template is the CONTROL program in which the status and error messages of the motion controller, controllers and application are detected and ordered.

As a result, the status of the events within the project is displayed legibly in the available terminal windows in MotionPerfect.

The status of the establishment of the EtherCAT connection, homing procedure and display of system, motion and application errors, such as limit switches or status emergency stop circuit, are therefore easy to find. This functionality saves valuable time during commissioning.

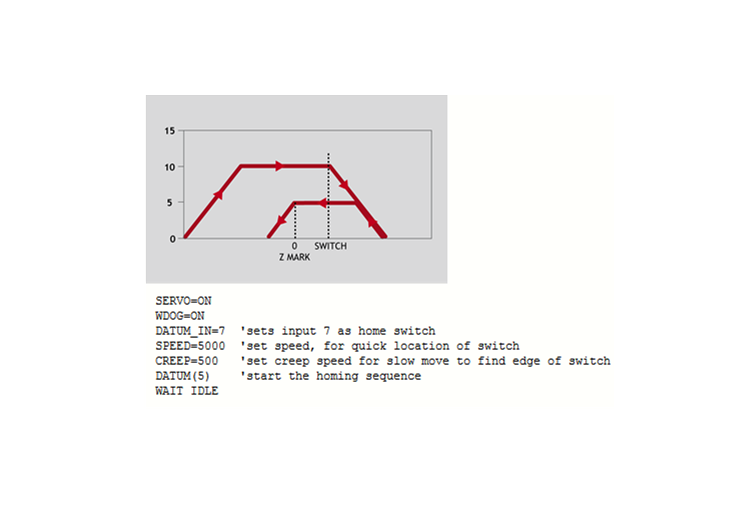

For every motion control application with a positioning issue, the system must be brought into reference at least once. The EtherCAT coupling of the Touchprobe function in the servo controllers makes it possible to use the encoder zero pulse when referencing. This makes all variants of the DATE function available in the motion controller. This feature makes it easy to apply the different methods of the homing procedure. A Trio MOTION-iX program HOMING can be used for this or a subroutine in the program APPLICATION.

In the Trio MOTION-iX program APPLICATION, there is room for the motion application itself in addition to a subroutine for the homing procedure.

This program can be completed by the customer himself using the motion commands described in the help file of MotionPerfect.

This process can be accelerated with training at ATB Automation or by having the entire project carried out by ATB Automation.

In all cases, the template forms a good basis with a consistent structure so that the design and commissioning of the project can be completed efficiently.

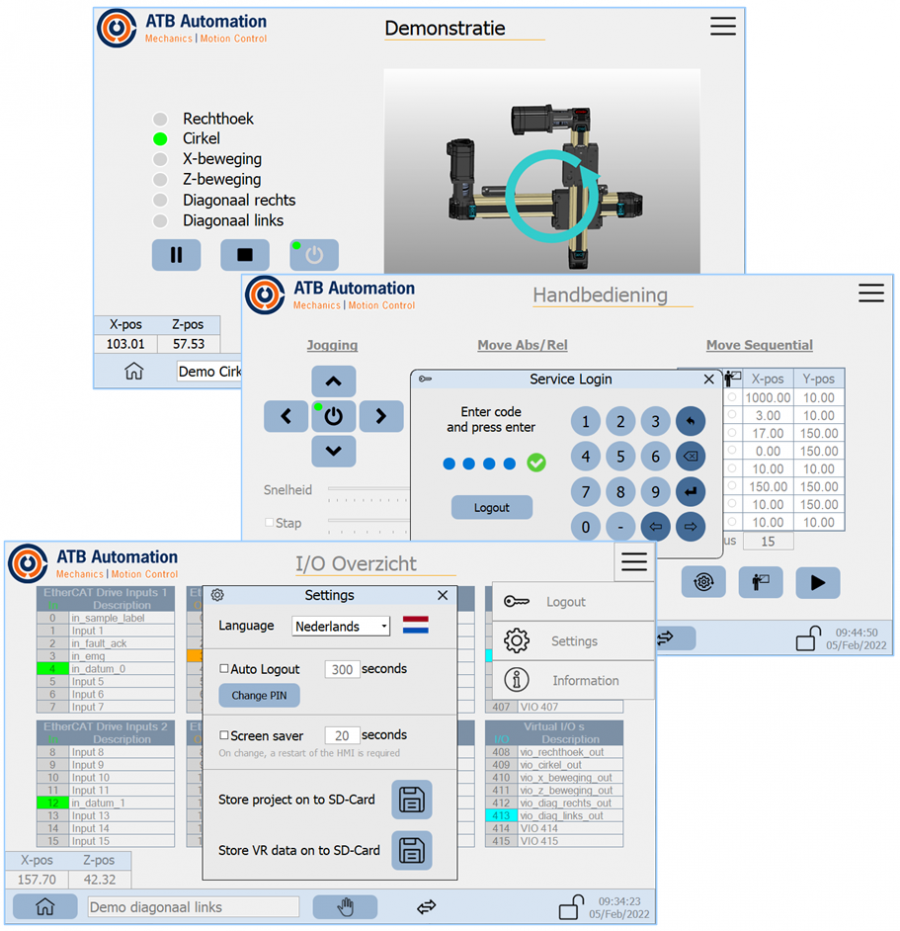

Pages are prepared in the template with a user-friendly and eye-catching layout. By using icons with description it is easy to navigate between pages and the menu. Preparations have been made to display system status in the bottom menu bar and error messages through pop-ups. Switching the interface language and making a backup of the system is possible. Any system settings that need to be protected can be placed behind a pin code.

Nous livrons des couronnes d’orientation, eléments oscillants, eléments tendeurs de stock et nous avons des renvoi d’angles, réducteurs servo et vérins-électromecanique dans notre gamme.

Nous sélectionnons et offrons les bons composants et systèmes pour solutions contrôle de mouvement, par exemple servomotorréducteur, servo-vérins lineaires à systèmes XYZ cartésien complet.

Dans le domaine en constante évolution des avancées technologiques, la technologie des vis à rouleaux est devenue une force majeure dans le...

ATB Automation utilisie des cookies pour le bon fonctionnement du site web.

Si vous utilisez notre site web,nous partons du pricipe que vous êtes d'accord.

Nous utilisons des cookies pour proposer certains de nos services. Un cookie est un petit fichier qui est envoyé avec les pages de ce site et enregistré par votre navigateur sur le disque dur de votre ordinateur. En utilisant ces cookies nous rendons nos services en ligne plus facile à utiliser, parce que ils nous permettent de mesurer et de personaliser. Aussi ils nous permettent par example de proposer des vidéos sur notre site web et de montrer des boutons de média social à suivre.

Les paramètres ci-dessous vous permettent de spécifier quels cookies vous acceptez. Veuillez noter qu'en ne pas acceptant tous les cookies, certaines parties du site ne fonctionneront pas correctement.