Aug

The cheapest energy is the energy you don’t use

"Approximately one third of motors are equipped with friction belt drives. The performance and efficiency of many belt drives can be improved through...

Date: 1 May 2024

A safe machine with minimal downtime, without compromises on performance because safety techniques throw a spanner in the works. “That sounds attractive, but will it certainly cost me a lot of time and money? Let alone the amount of testing and programming work I have to do during the design process?” All unnecessary worries, thanks to Stöber safety technology. I'll explain why.

In this blog I will tell you:

Although I like to think in terms of challenges, some engineers see safety technology as something that can potentially cause problems.

Admittedly, I can imagine that this is not the most favorite part of the design process for some machine builders. They prefer to develop the functionalities of the machine.

But where safety technology is seen as a separate topic, this has a direct influence on the functionality of the machine. Because when safety comes into action, it overrules all actions of the machine and comes to a standstill.

In other words: one (safety) absolutely affects the other (functionality).

The video below explains this principle in 2 minutes:

Allright. So stop = stop, but immediately switching off the power is not always desirable. And if it does happen, it takes a lot of time to put the machine back into service.

But what if I told you that we don't just have to think from a standstill, but that there are many more safety options?

Get to know the SE6 safety module for the SD6 servo drive from Stöber:

The best way to explain what this looks like in practice is through an application at a customer.

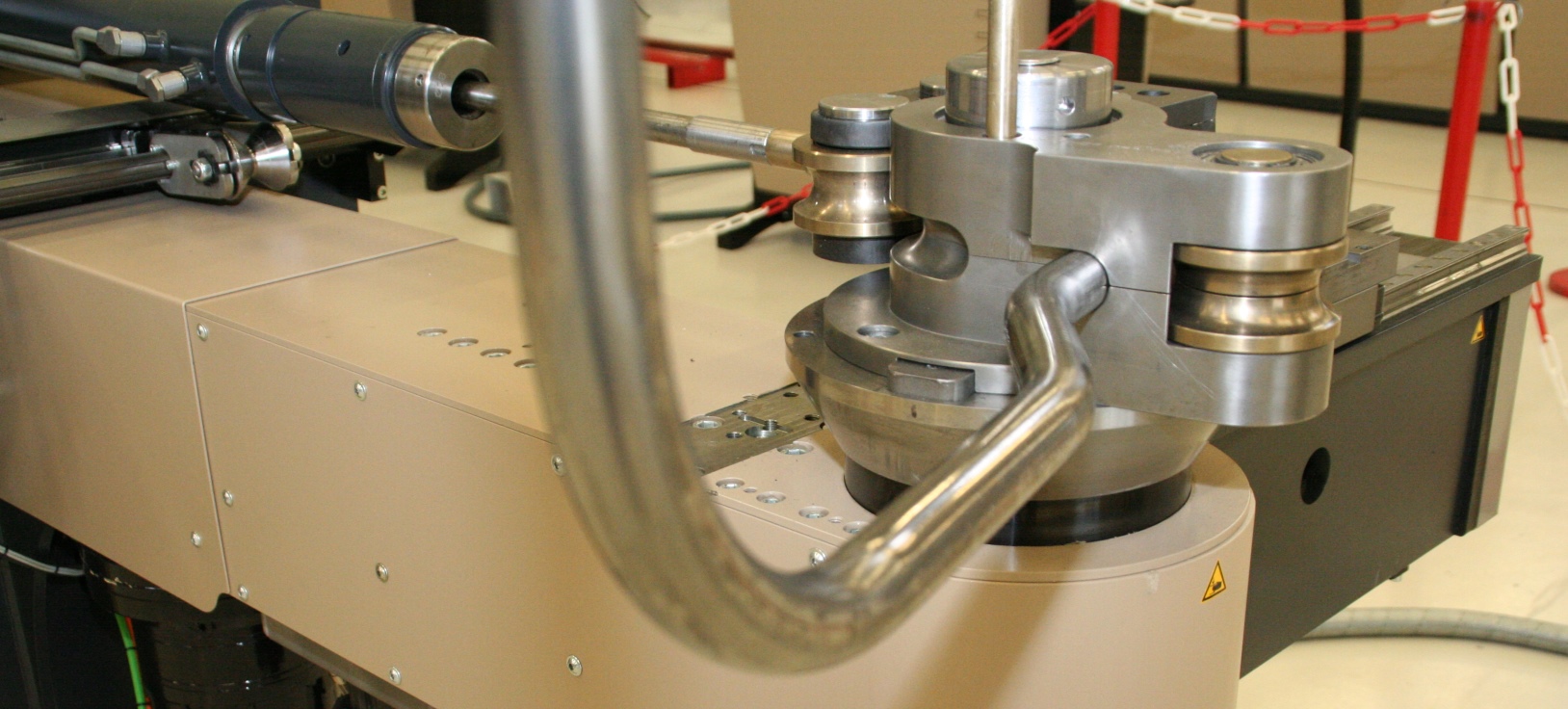

One of our renowned customers is a manufacturer of high-quality CNC bending machines. These machines are used for bending pipes for furniture and automotive applications, among other things.

The SE6 safety module is used in their bending machines for the safety monitoring of movements around the machine.

The machine is equipped with sensors that register when a person is too close to the machine. This slows down the application by means of the safety function Safe Limited Speed (SLS) The safety module SE6 carries out a check and provides immediate feedback: is the person in question within a critical distance of the machine? Or is the machine not fast enough at a safe speed? Then the Safe Stop safety function (SS1 or SS2) becomes active and the machine will stop within the guaranteed response time of <10 ms. to a controlled standstill.

After this controlled stop, the machine can be restarted quickly without valuable time being lost testing and resetting the machine.

This example makes it clear: with this solution you have total control over all safety functions and you will not suffer from unnecessary downtime.

This brings me to another aspect of cost efficiency: by using the Stöber SE6, no additional components are required, such as additional encoders or special motors. If this is the case, in addition to the purchase costs, you will also incur costs for the strictly specified installation of these additional components.

In the event of a machine malfunction, a specialized technician must visit to test the components and replace them if necessary. When you are charged every hour, the costs can increase significantly. What a waste!

Total control over the safety functions, what does that actually look like? All functions are defined in the PASmotion software from Pilz, which is integrated into DriveControl Suite setup software from Stöber

A matter of drag & drop, without complex programming actions. All settings are secure and stored in the software and can be consulted or adjusted at any time after entering a PIN code.

By integrating safety technology into your application, we can make machines more reliable, faster and more efficient. Resulting in less downtime. Last but not least: apart from the many (economic) benefits mentioned above, I think it is important to emphasize that it is ultimately about creating an environment in which humans and machines can work together safely.

Because a properly functioning application is important, but personal safety is the most important thing. So: “Designing for humans”.

Questions? Ideas? Or want to know how you can apply this safety technology in your machine? Contact me.

+31 297 38 05 63

peter@atbautomation.eu

Peter Hamersma has been working at ATB Automation since 2001, starting as a software engineer. Peter is responsible for supervising the motion control projects of ATB Automation and, as a specialist in servo drives and motion controllers, he is also responsible for system integration. With more than 25 years of experience in the field of servo systems and the motion controllers of Trio Motion Technology, Peter is one of the most experienced specialists in the Benelux.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.