Jul

Roller Screw versus Ball Screw Actuators

In the ever-evolving field of engineering, roller screw technology has become a significant force in linear electric actuator motion control....

Date: 5 September 2018

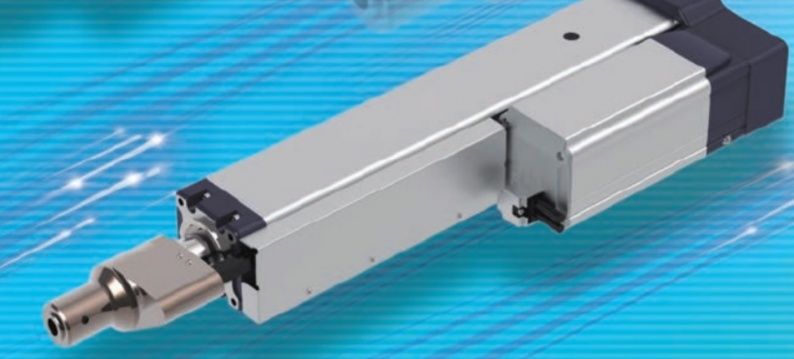

IAI Industrial robots has launched a new range of servo actuators with an integrated load cell: ServoPress actuators.

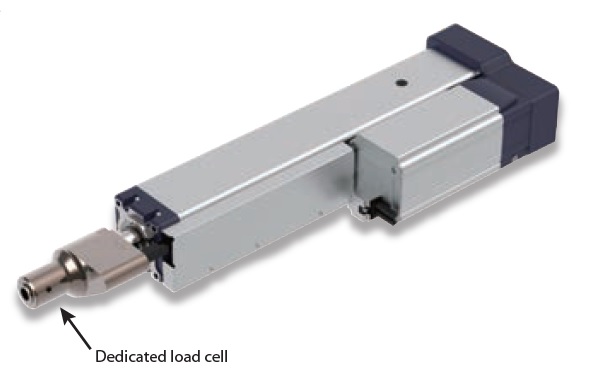

The actuator is composed of a 230V servomotors with absolute encoder, a ball screw spindle and a rod with load sensor.

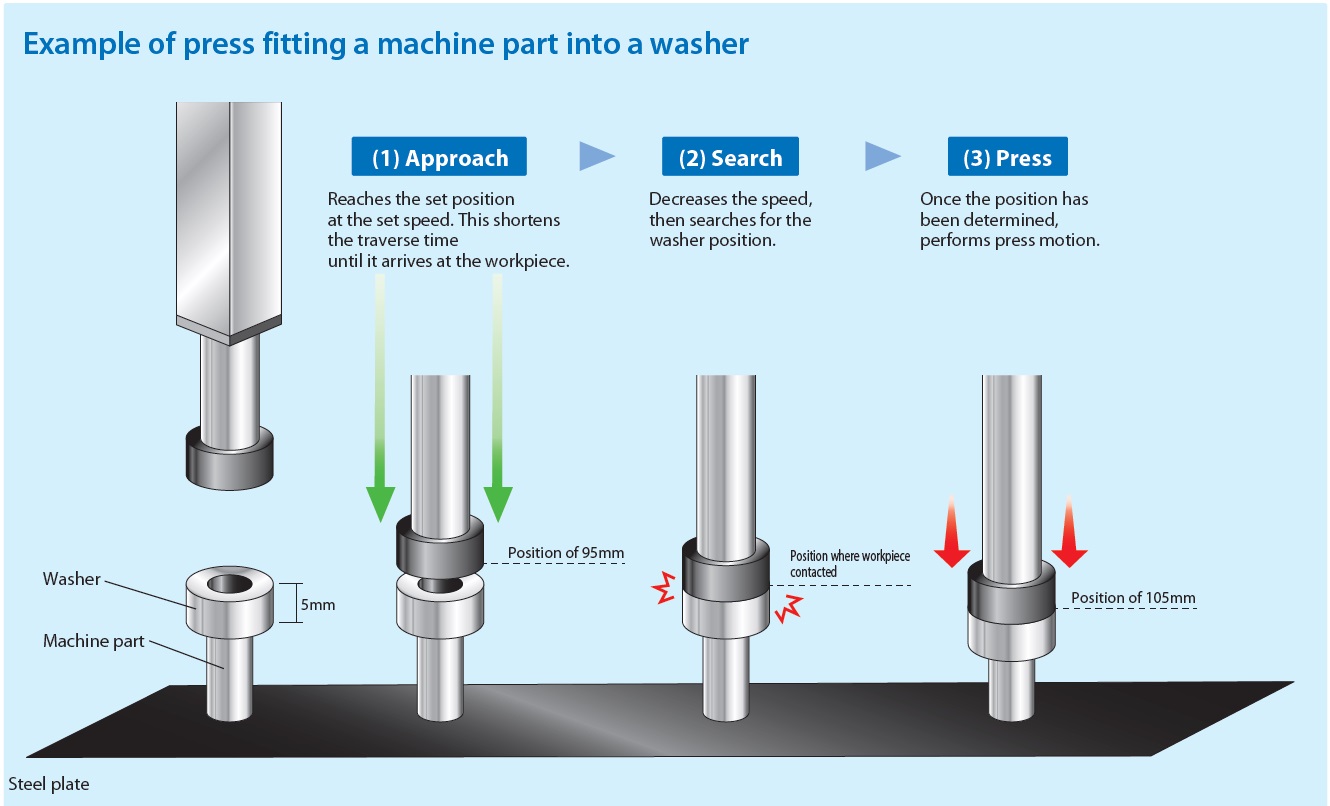

Compared to hydaulic or pneumatic actuators, this electric actuator is easy to realize press applications due to the extremely accurate position control, in combination with a simple setting of a pushing force.

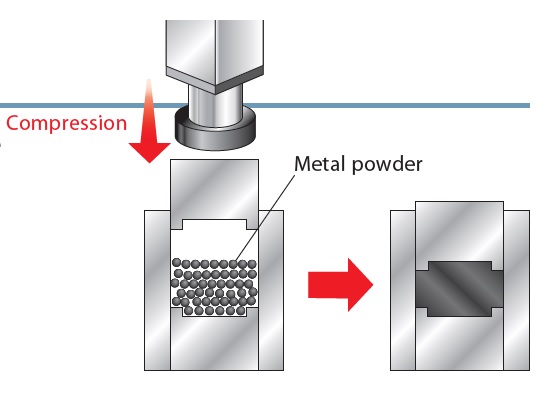

Similar to an air or hydraulic cylinder, the purpose of the pushing movement is to press the rod against the workpiece. The servo press functionality gives superior stability during pressing, making the actuator optimal for simultaneous push and motion. The servo press actuator can be used for a large number of different applications that require a strong pushing force, such as a press fit and sealing.

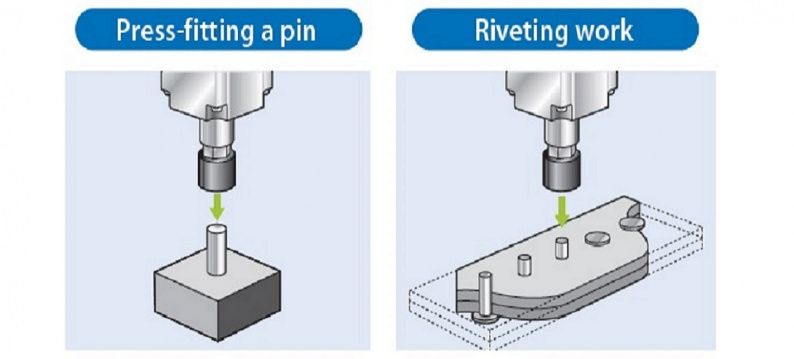

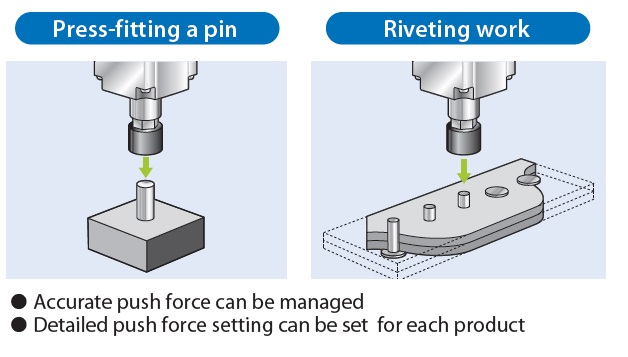

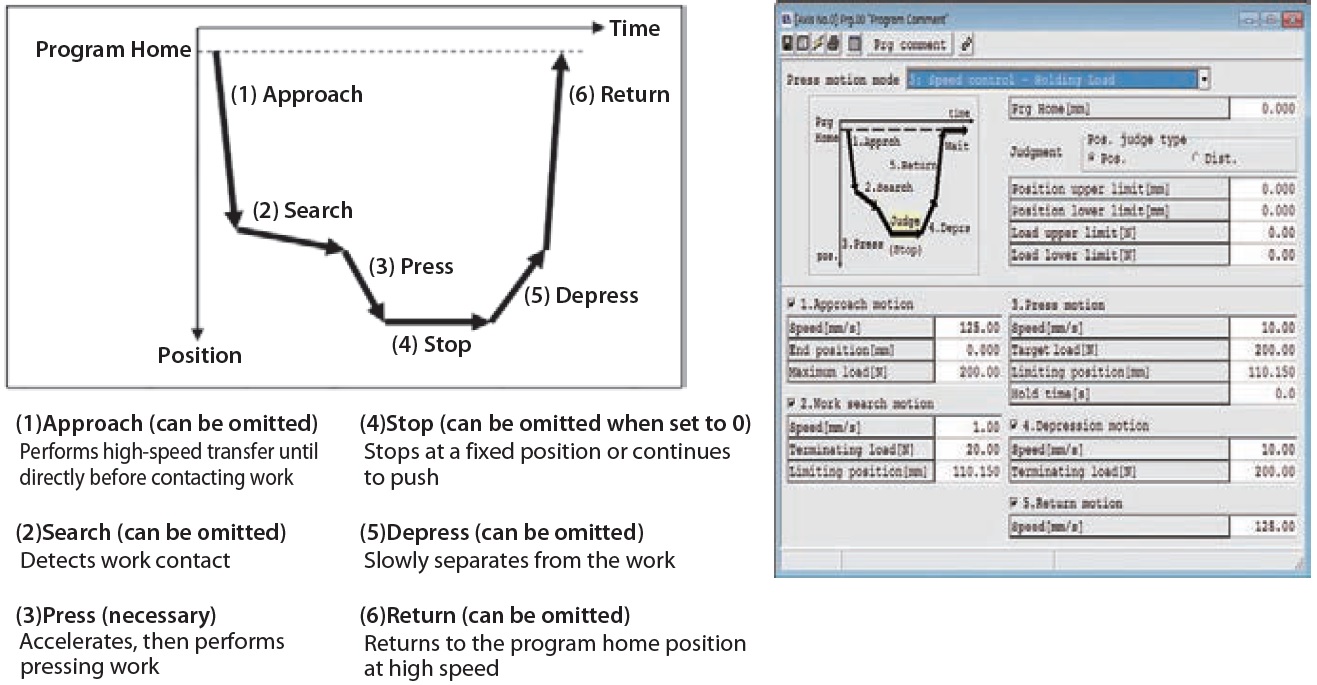

Force Control is a function that can execute very precise pressure force using the feedback data of the special load cell installed in the actuator. With the special press program software from IAI, different push-motion operations can be performed.

The actuator is equipped with a special load cell on the rod tip to detect the load applied to the pressed object. This provides an extremely precise load control with a repeat accuracy of ± 0.5% F.S. (Full Scale).

The RCS3-RA15R / RA20R servospress actuators can reach a maximum pushing force (30000N / 50000N) with a pushing time of 9s / 10s. They can be used for applications where the time is reached until a predetermined pushing force is undetermined, such as:

With the set-up software press-programming one of the two control methods, "Speed Control" or "Force Control", can be selected. In addition, one of the four stop conditions, "Position", "Distance", "Load" or "Incremental load" can be selected as a function to stop. By using a total of eight types of press methods, it is possible to realize a diversity of press movements.

Send an email to iai@atbautomation.eu or call Martin van der Steenhoven (+31 297 38 05 54)

You can also download the catalog here

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.