Mar

Rosta: solutions for the recycling industry

The recycling industry is constantly innovating. With an increasing amount of waste and the need to process it in a sustainable way, the demand for...

ROSTA was established as a sole proprietorship more than 75 years ago in Hunzenschwil, Switzerland. ROSTA is the leading troubleshooter for bearings, springs, shaking and anti-vibration of machine parts and systems. ROSTA is the world No1 manufacturer for rubber suspension components. ATB Automation is a partner of ROSTA rubber suspension units and responsible for customers in the Benelux.

For over 75 years the use of the ROSTA rubber spring elements have reached many industries. Almost every day we find new solutions where our customers have implemented one or more of our elements in their applications, making them more competitive and profitable.

ROSTA is being used in many industries:

In 1941, the single axis wheel suspension developed ROSTA rubber suspension was combined in a compact construction with the wheel bearing features, suspension and rubber slowness, also those of anti-vibration mounts.

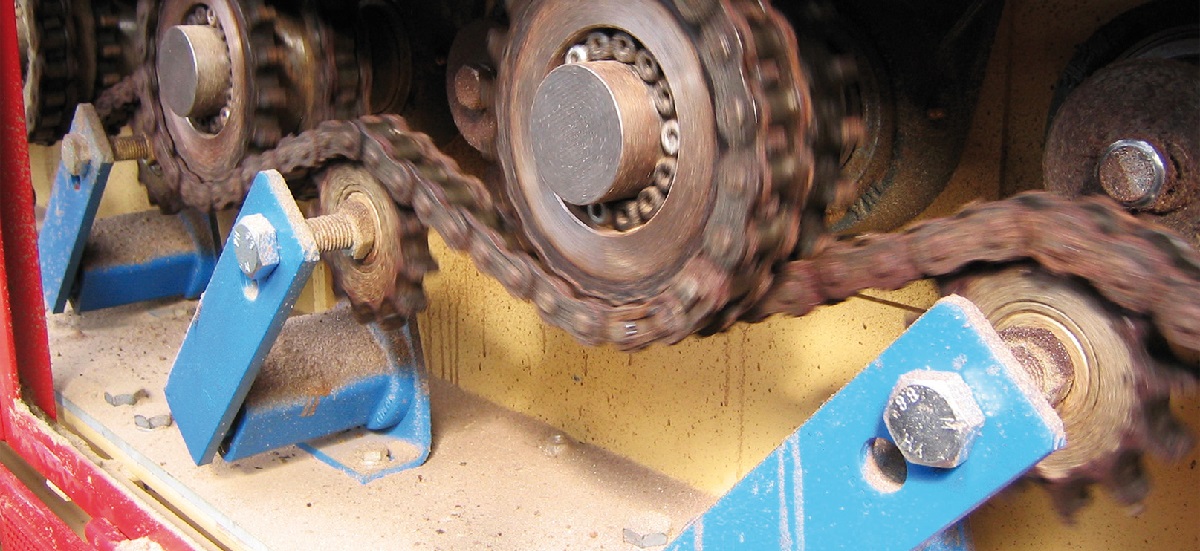

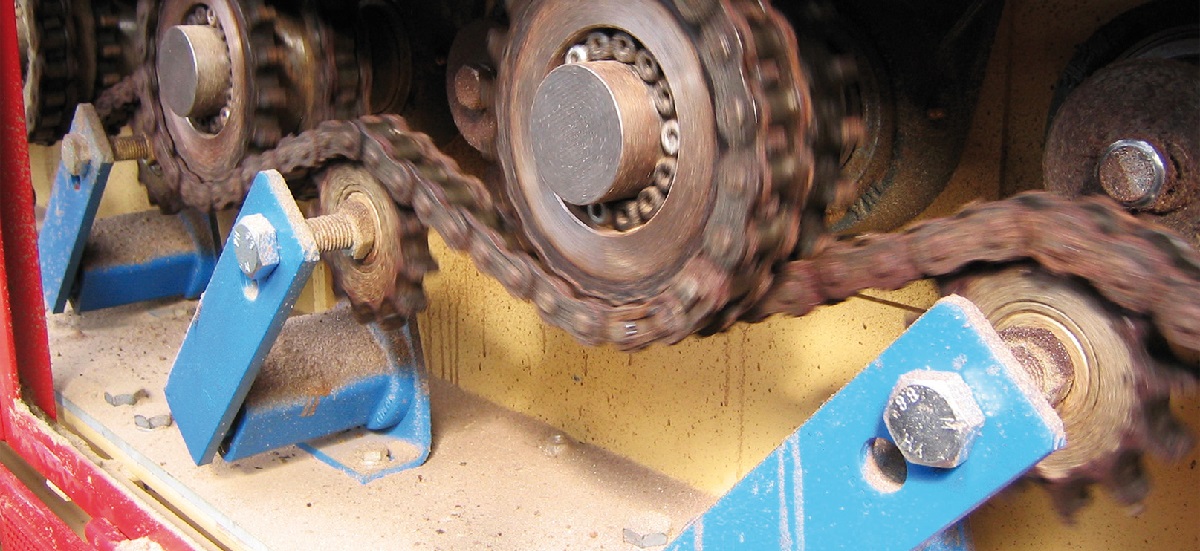

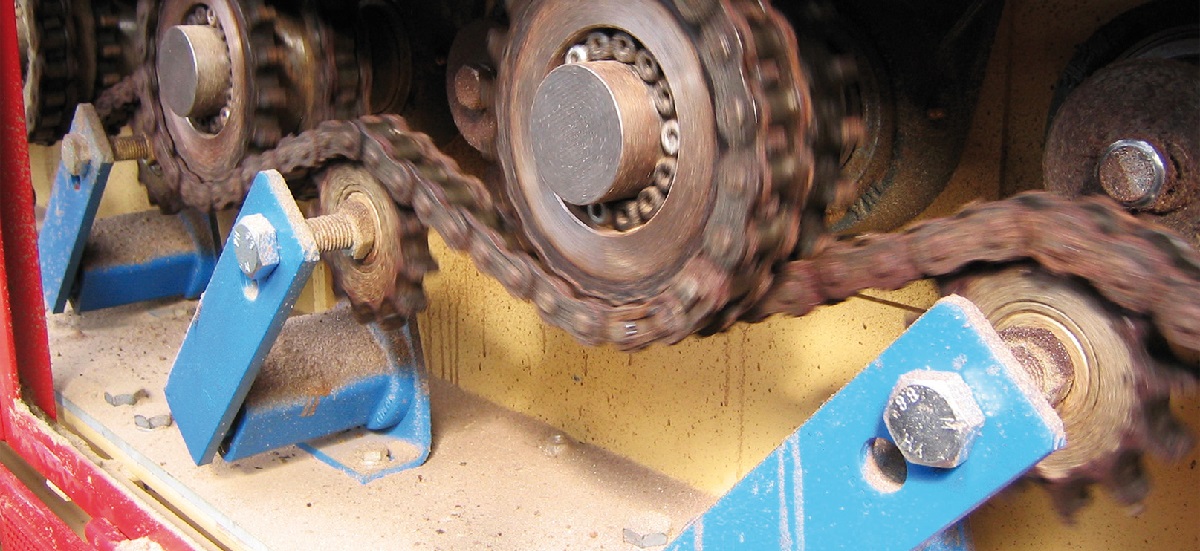

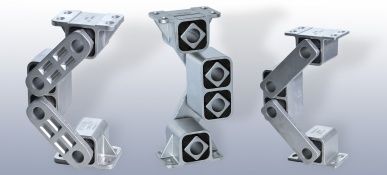

ROSTA has focused on the production of machine components at an early stage. Automatic tensioner devices were the first ROSTA machine components, which were manufactured in large series based on the same suspension principle.

Nowadays the elements for shaking and resilient support for supply and transport tunnels are the main focus in the production of ROSTA AG. Anti-vibration mounts also represent an important manufacturing share.

Many millions of ROSTA elements are used worldwide and show impressively that the ‘ROSTA Blues’ form a recognized industry standard.

With a clear grow strategy, ROSTA is expanding on all levels. ROSTA has besides the headquarters in Hunzenschwil six subsidiaries and over 35 distribution partners worldwide.

ROSTA has a well-equipped Research and Development department that leaves nothing to chance; the material tests that take place before and periodically during the series production are the guarantee for a comprehensive quality standard. Production machines, handling equipments, tooling machines and processing systems are equipped with state-of-the-art technology. Quality validation obtains highest importance at ROSTA.

Ideal ‘building rocks’ for modern engineering

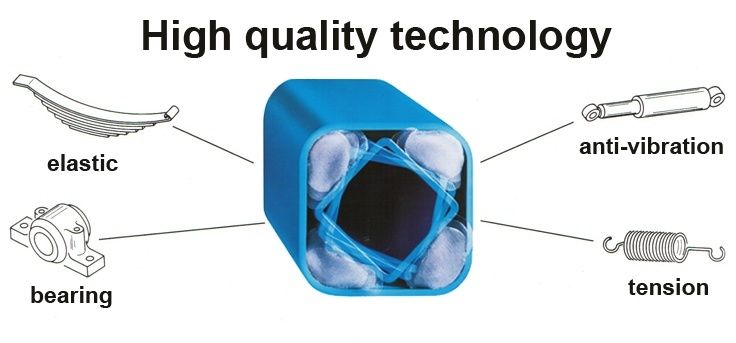

The ROSTA suspension unit is a machine component with a multiple function:

Advantages ROSTA rubber suspension units:

The complete range Rosta tensioner devices, oscillating mountings, rubber suspension units, anti-vibration mounts and motorbases is recorded in a catalog.

The recycling industry is constantly innovating. With an increasing amount of waste and the need to process it in a sustainable way, the demand for...

ROSTA is the world No1 manufacturer for rubber suspension components. Besides the classic construction with 4 natural rubber elements a new element...

This year ROSTA proudly looks back on 75 years of successful company history and innovation. This milestone is celebrated with a new logo. With 120...

After the introduction of the steel HS mountings in 2009, Rosta now has the RVS oscillating mountings for pending oscillating/ tensioning...

The Rosta AB oscillating mountings are the ideal solution for vibrating sieves and shaking conveyors. The simple mounting, the optimal damping of all...

The Rosta ATEX motorbase is a maintenance-free mechanical pretensioning unit, offering the ideal belt tension. This force is developped according to...

Breakage of steel springs in a shaker conveyor or vibrating screen is a common shorcoming. Replacing such a broken steel spring causes irritation and...

Rosta is well known in general engineering with rubber suspension units and its numerous applications. Rosta is also often used in the food industry...

ATT from Aalsmeer has developed a special braking system for for flower cars from Flora Holland. At the flower auction previously when the floorlevel...

"Approximately one third of motors are equipped with friction belt drives. The performance and efficiency of many belt drives can be improved through...

ATB Automation as exclusive ROSTA distribution partner for the BENELUX, has a considerable available stock, in particular the share of stainless...

What a strong headline of a blog! But what do I exactly mean by it? I will try to explain this as optimally as possible. I’m wondering if you...

With great expectations I was looking forward to it. I went to Rosta in Switzerland for a basic product seminar. On Monday, June 26th, I left from...

Many of our customers use belt scrapers for rubber conveyor installations. Not only end users, but also the machine manufacturers. The need for belt...

Location Netherlands

Vermogenweg 109

NL-3641 SR MIJDRECHT

THE NETHERLANDS

Contact information:

Tel +31 297 28 58 21

Location Belgium

P. Basteleusstraat 2 - Unit 11

B-1600 SINT-PIETERS-LEEUW

BELGIUM

Contact information:

Tel. +32 2 588 80 05

Benelux

ATB Automation

Vermogenweg 109

NL-3641 SR MIJDRECHT

NETHERLANDS

Benelux

VAT NL 003226591B01

Chamber of Commerce 30100549

IBAN NL93 HAND 0784 5271 80

BIC HANDNL2A

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.